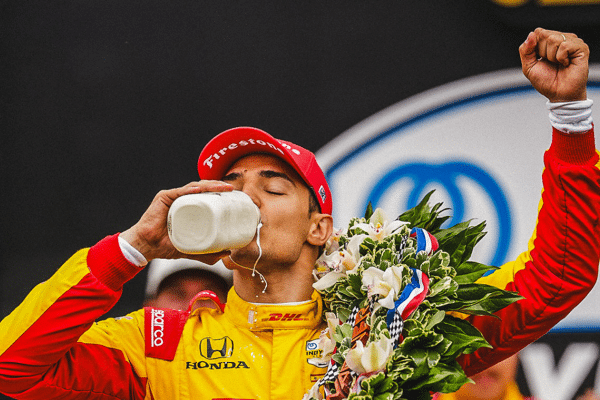

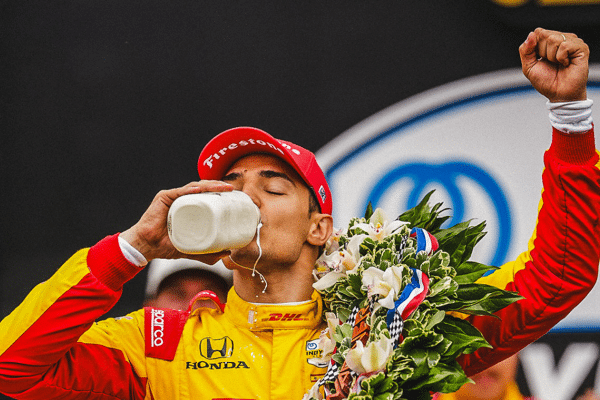

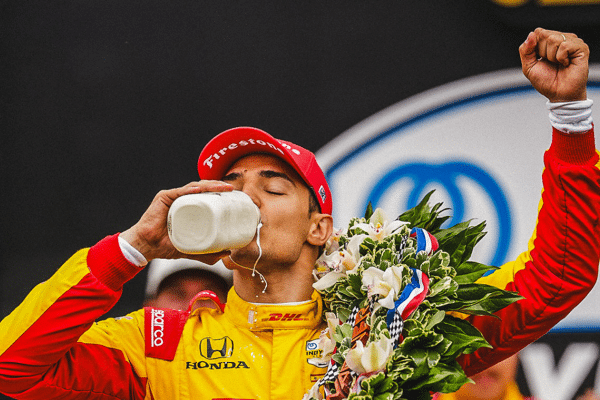

Chip Ganassi Racing gewinnt das 109. Indianapolis ...

Alex Palou gewinnt die 109. Indianapolis 500 für Chip Ganassi Racing. Eurol hat als technischer Partner einen wesentlichen Beitrag zu dieser Leistung geleistet.

26. März 2020

All eyes were on the first hybrid truck in the Dakar Rally, manned by pilot Gert Huzink, navigator Rob Buursen, and initially mechanic Martin Roesink, who had to drop out just before the start of the sixth stage due to a broken vertebra. This last issue was a setback for the team, but the Riwald Dakar Team's Renault C460 Hybrid Edition bravely fought its way through the desert and reached the finish line without insurmountable technical issues. Given the completely new, experimental technology on board, this can be considered a significant achievement. However, helmsman Huzink seems unimpressed with the 24th place in the final standings. "We had tested everything extensively because we wanted to play it safe. On the other hand, no matter how thorough your preparation, Dakar remains unpredictable. If you roll over six times on day one, the party is immediately over. Either way, we are confident that there is plenty of potential in the hybrid technology and in the truck as a whole to perform even better next year. The speeds were higher than ever."

A year and a half ago, the Riwald Dakar Team came up with the idea of adding a green touch to their participation in the monstrous rally. "Within my business, Riwald Recycling, we always try to be at the forefront of our industry in terms of sustainability. If you strive for that all year round, it's hard to justify participating in a two-week rally that emits a lot of gases. We wanted to turn it around and make the Dakar adventure a business card for the company. We considered other options besides hybrid drive, but those are either not feasible or still too risky or costly. Natural gas carries too much risk, hydrogen is in its infancy, and electric has the problem that the batteries don't last in terms of capacity if you cover 700 to 1000 kilometers per day under full load. Yes, you could install a larger battery pack, but then the truck would weigh ten tons, and you would no longer be a serious contender. Besides the green business card, competition is our other main goal."

Technical partner MKR Technology in the Czech Republic took on the hybrid project together with the Riwald Dakar Team, fully supported by Eurol, Hendrickson, AxleTech, and Renault Trucks. Huzink: "This fits in with the goals of these companies, as the transport sector needs to make a leap in terms of sustainability, and this is obviously the ultimate test. So, we are doing important development work for commercial goods transport. Not only in the Dakar Rally, but we are also using the Renault C460 Hybrid Edition in the Morocco Desert Challenge, the Silk Way Rally from Russia to China, and the Rallye du Maroc. In the next rally, we hope to benefit from the technical improvements that came to light in Saudi Arabia. Oddly enough, these had nothing to do with the new hybrid components but rather with the tried-and-tested technology on board, like the axles and the differentials."

According to Huzink, the conventional components of the drivetrain in particular were heavily stressed during this Dakar edition. "This was due both to the long distances and the fact that we were now driving at 95% instead of 85 to 90. You always have to keep some buffer for unexpected situations, like a pothole or a cliff you didn't see coming. In addition to the competition, we were keen to finish the rally to gather enough information about the functioning of the hybrid concept." The fact that the Riwald Dakar Team dared to narrow the margin to the ultimate limit is remarkable, especially with such experimental technology on board. "For starters, we could demand more from the diesel engine—a 11.0-liter six-cylinder from Volvo with a single turbo—since its power has been reduced from 1050 to 850 hp, which is compensated by the electric motor. This means less wear and tear and at the same time lower consumption, regardless of the impact of the hybrid system."

The Renault C460 Hybrid Edition is also much easier to handle than its predecessor, the K520, Huzink points out. "It's lighter, a bit wider and lower, which is beneficial for the center of gravity. Believe it or not, it drives almost like a buggy. You can throw it around and drift wonderfully." A lower mass is the last thing you'd expect from a vehicle with a heavy battery pack on board, especially knowing that the complete hybrid system adds some 650 kilograms. "Nevertheless, this Renault weighs a ton less than its predecessor, namely the exact minimum allowed in the Dakar Rally: 8.5 tons. We have a completely newly constructed truck, where weight savings were applied on all fronts, down to the smallest parts. To my knowledge, we are the first team in our category to use a chassis made of steel and aluminum, bonded together using a new process. The cabin must not deviate from the model for the commercial market by regulation, but Renault is the only truck manufacturer that provides carbon doors, so we have those."

The German company ZF supplied the CeTrax Lite RS electric motor and the automatic transmission, which was slimmed down by MKR Technology. "It is now lighter and more compact, converted from seven to six gears," said Gert Huzink. "Six years ago, we were the first truck team in Dakar to drive with an automatic transmission; now competitors do it too. Thanks to the paddle controls on the steering wheel, you can switch gears lightning fast, which saves you under difficult conditions, like in the dunes. During a climb on loose sand, you don't want the power to be interrupted for too long, as you will get stuck faster." Compared to the perpetual dominance of Kamaz – the factory team that can test all year round on its own grounds – the Riwald Dakar Team had an advantage in Saudi Arabia: the constant torque of the supporting electric motor. "There's no more turbo lag, and you feel the power immediately increase after a corner or uphill. Even after a dip, you always make it to the top the first time and don't need to circle around for a second attempt."

Overall, the speeds were higher than ever, reaching up to 110 km/h on certain trials. Considering that we consumed over thirty percent less fuel during this Dakar edition and therefore needed to carry less on board, you can say that we have taken a big step forward in both competitiveness and sustainability. These were precisely our two goals."

While an electric motor generally doesn't require lubrication, the drivetrain of the Renault C460 Hybrid Edition received special attention from Eurol, a project partner and also a supplier for the other Dakar trucks prepared by MKR Technology. "Due to the insanely high torque of the electric motor, much more force is applied to the final drive," said Dirk van der Veen, Business Development Manager at Eurol Specialty Lubricants. "The transfer case has to handle 24,000 Nm. We use a liquid grease, Bio Grease SI-000/101-S, which keeps the metal temperature 20 degrees lower and drastically reduces wear. Previously, the team had to regularly replace the complete set of planetary gears during Dakar; now, the wheel hubs last the entire rally."

"This edition in Saudi Arabia was technically demanding. The long distances and high speeds were a challenge for the differential, putting a strain on the lubrication used. We are currently investigating how to improve it in this area," said Van der Veen. According to him, the lubricant manufacturer from Twente has already made significant progress in collaboration with MKR Technology. "For the wheel bearings and the universal joints of the drive shafts, we use Eurol Grease CS-2/103-S, which largely keeps out sand and water. If they do penetrate, they are neutralized, and the lubricating effect remains intact. This makes a huge difference in terms of wear. For engine oil, Eurol Geo-Max 10W-40 works excellently, although it is used in combination with Additive-S Engine, which significantly extends the lifespan of the rotating parts under extreme stress. Previously, the team had to revise the piston rings and cylinder liners every 8000 to 9000 kilometers. Now, they don't even show wear at that point. We have another innovation in the pipeline, but I can't talk about it yet."

Alex Palou gewinnt die 109. Indianapolis 500 für Chip Ganassi Racing. Eurol hat als technischer Partner einen wesentlichen Beitrag zu dieser Leistung geleistet.

Nach fünf harten Dakar-Etappen genießen die Eurol-Teilnehmer einen wohlverdienten Ruhetag. Beide Teams erlebten Erfolge und Rückschläge.

Eurol wird als technischer Partner im INDYCAR SERIES-Saison 2025 mit Chip Ganassi Racing zusammenarbeiten.

Eurol unterstützt Top-Teams, die bereit für die 47. Ausgabe der Dakar-Rallye sind, die vom 3. bis 17. Januar 2025 in Saudi-Arabien stattfindet.

Alex Palou gewinnt die 109. Indianapolis 500 für Chip Ganassi Racing. Eurol hat als technischer Partner einen wesentlichen Beitrag zu dieser Leistung geleistet.

Nach fünf harten Dakar-Etappen genießen die Eurol-Teilnehmer einen wohlverdienten Ruhetag. Beide Teams erlebten Erfolge und Rückschläge.

Eurol wird als technischer Partner im INDYCAR SERIES-Saison 2025 mit Chip Ganassi Racing zusammenarbeiten.

Eurol unterstützt Top-Teams, die bereit für die 47. Ausgabe der Dakar-Rallye sind, die vom 3. bis 17. Januar 2025 in Saudi-Arabien stattfindet.