Lubrificação de fusos

Lubrificação confiável de fusos com Eurol Grease CS-2/502-S. Evite desgaste, vazamentos e ressecamento com a proteção duradoura da SYNGIS Technology.

8 de fevereiro

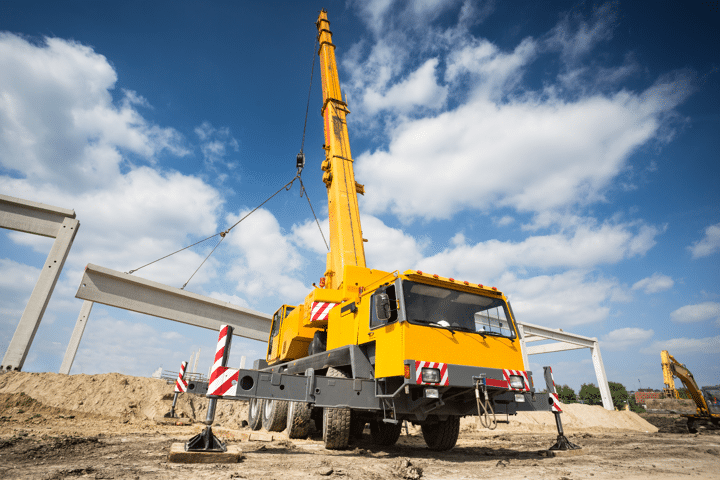

Escolher massas lubrificantes tradicionais para a lubrificação das seções telescópicas e dos cabos de gruas traz várias desvantagens:

1. Perda excessiva de óleo e consistência inadequada

Massas antigas, como as pretas, tendem a perder óleo — fenómeno conhecido por oil bleeding. Isso torna a massa mais espessa e menos eficaz, especialmente em dias quentes. Este problema é facilmente visível nos tambores de massa, onde o óleo se separa da estrutura.

2. Propriedades anti-desgaste insuficientes

As massas antigas não suportam adequadamente as cargas pesadas a que as partes deslizantes das gruas estão sujeitas. Isso causa desgaste excessivo, encurtando a vida útil dos componentes e aumentando os custos de manutenção.

3. Fraca resistência à água e corrosão

Sob a massa, pode surgir corrosão nas partes deslizantes da grua, especialmente em ambientes húmidos ou costeiros. Este tipo de dano implica reparações dispendiosas e paragens não planeadas.

4. Contaminação do ambiente e da oficina

As massas pretas tornam a manutenção das gruas suja e difícil. As mãos, ferramentas, roupas de trabalho e a oficina ficam contaminadas, criando um ambiente de trabalho desagradável.

Para a lubrificação das partes deslizantes de gruas telescópicas, ainda se utilizam frequentemente rolos ou pincéis tradicionais. Isso resulta numa aplicação irregular da massa e num trabalho sujo, com excesso de produto a escorrer. Uma solução inovadora é a pistola de massa por pressão de ar da Eurol. Esta ferramenta avançada permite uma aplicação uniforme e limpa da massa nas superfícies telescópicas, tornando o processo de lubrificação simples e eficiente. Reduz o desperdício, garante uma camada homogénea de lubrificante nas partes deslizantes e contribui para um ambiente de trabalho limpo.

FPara proteger e lubrificar cabos de aço, a Eurol oferece o Lube PL. Este produto — disponível em jerricans, bidões e spray — penetra profundamente no cabo e forma um filme lubrificante limpo, transparente e resistente à água. O Eurol Lube PL protege contra a corrosão e mantém o cabo flexível, além de facilitar a inspeção visual quanto a ferrugem ou danos.

Para a lubrificação das partes deslizantes de uma grua telescópica, a Eurol oferece a Grease CS-2/103-S, uma massa moderna de cor clara que pode ser pulverizada nas superfícies com uma pistola de ar comprimido. Esta massa não liberta óleo (sem oil bleeding) e tem uma elevada resistência à água. Adicionalmente, existe o Eurol Lube CL-F, uma alternativa em óleo líquido para clientes que preferem este tipo de lubrificante. Ambos os produtos oferecem elevada proteção contra corrosão e desgaste, mesmo em ambientes marítimos, graças à Eurol SYNGIS Technology incorporada nas duas formulações. Para quem procura soluções ecológicas, a Eurol também disponibiliza alternativas biodegradáveis.

Para garantir uma lubrificação eficaz, as partes deslizantes das gruas telescópicas devem ser limpas cuidadosamente antes da aplicação do novo lubrificante. A remoção da massa antiga e sujidade incrustada é essencial para assegurar a eficácia do novo produto. A Eurol desenvolveu o Eurol Swift Clean 110 precisamente para esta finalidade. É importante certificar-se de que eventuais resíduos do agente de limpeza não interfiram negativamente com as propriedades do lubrificante aplicado de seguida. Para quem prefere um agente de limpeza biodegradável, a Eurol também dispõe de alternativas apropriadas.

A importância de uma lubrificação moderna e adequada para gruas telescópicas e gruas montadas em camiões não pode ser subestimada. A utilização de massas pretas e de gerações antigas traz desvantagens significativas. Ao optar por lubrificantes modernos, como os mencionados lubrificantes Eurol Specialty, é possível melhorar o desempenho dos equipamentos pesados no transporte vertical, resultando numa maior eficiência e fiabilidade operacional.

Lubrificação confiável de fusos com Eurol Grease CS-2/502-S. Evite desgaste, vazamentos e ressecamento com a proteção duradoura da SYNGIS Technology.

As caixas de engrenagens industriais exigem uma lubrificação fiável para evitar perdas de energia, desgaste e paragens não planeadas. Neste artigo ficará a saber como as es...

O sal e as cargas pesadas causavam falhas no sistema de carga da Bolk Transport. Com o Eurol Lube CL-F Spray, tudo voltou a funcionar sem problemas.

A má qualidade do gasóleo provoca injetores contaminados e problemas no motor no setor dos transportes. Descubra como uma adição inteligente ao combustível não só reduz as ...

Lubrificação confiável de fusos com Eurol Grease CS-2/502-S. Evite desgaste, vazamentos e ressecamento com a proteção duradoura da SYNGIS Technology.

As caixas de engrenagens industriais exigem uma lubrificação fiável para evitar perdas de energia, desgaste e paragens não planeadas. Neste artigo ficará a saber como as es...

O sal e as cargas pesadas causavam falhas no sistema de carga da Bolk Transport. Com o Eurol Lube CL-F Spray, tudo voltou a funcionar sem problemas.

A má qualidade do gasóleo provoca injetores contaminados e problemas no motor no setor dos transportes. Descubra como uma adição inteligente ao combustível não só reduz as ...