The cooling strategy of Volvo heavy duty engines

Why local heat is decisive for the cooling strategy of Volvo heavy duty engines and what this means for coolant selection and maintenance.

February 1, 2024

Lubricants based on these technologies not only provide energy savings but also offer improved protection against wear and leakage, prevention of downtime, and lower maintenance costs.

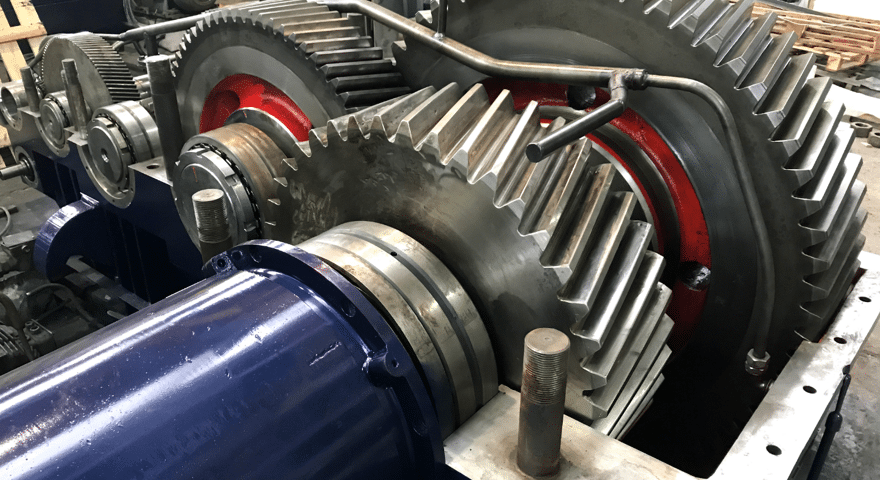

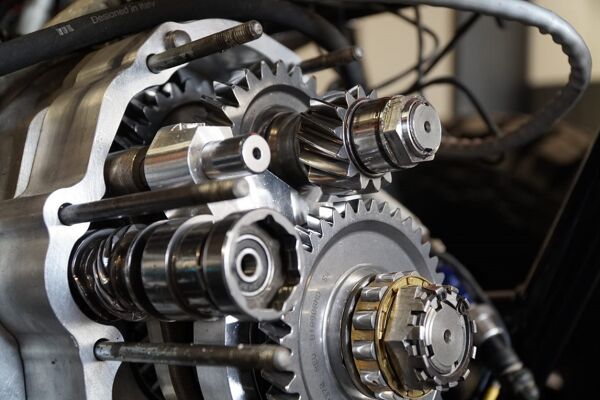

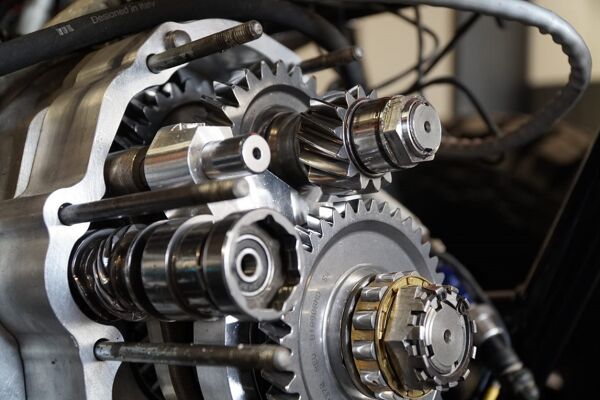

We offer the 'Eurol SYNGIS Technology' in our Specialty lubricants. This technology has been specially developed to combine energy savings with high anti-wear properties. Eurol Additive-S oil additive contains this SYNGIS Technology. By adding this product to a regular ISO 220 gearbox oil, the friction in the gearbox is reduced by up to 15%. This oil additive significantly reduces friction, resulting in a gearbox consuming less energy and therefore producing less heat. Infrared thermal imaging is an effective and simple way to observe these improvements.

For energy-efficient lubrication of gearbox bearings, Eurol E Heavy Duty Grease HY-2/103-S with SYNGIS Technology is suitable. The use of this grease leads to a reduction in friction, which in turn results in significant energy savings. The bearings are not only lubricated more efficiently but are also much better protected against wear, thereby extending their lifespan and preventing unexpected downtime.

For those considering switching from oil lubrication to grease lubrication of the gearbox, the new liquid grease Eurol E Heavy Duty Grease HY-000/101 is a good choice. This liquid grease with Eurol SYNGIS Technology is specially designed to combine energy savings with high anti-wear properties. Additionally, this switch from gearbox oil to liquid grease as gearbox lubrication offers an added advantage: a much lower risk of leakage through the gearbox seals.

Why local heat is decisive for the cooling strategy of Volvo heavy duty engines and what this means for coolant selection and maintenance.

Industrial gearboxes require reliable lubrication to prevent energy loss, wear, and downtime. In this article, you will learn how modern lubrication strategies – from advan...

In the first editions of the Dakar Rally with The Beast, a standard 75W-140 transmission oil was used. This resulted in a rather large amount of wear particles (iron and co...

Using Eurol Assembly Paste HT/FD for drilling equipment in the steel industry prevents carbonization, extends machine lifespan, and reduces downtime, saving over €50,000 an...

Why local heat is decisive for the cooling strategy of Volvo heavy duty engines and what this means for coolant selection and maintenance.

Industrial gearboxes require reliable lubrication to prevent energy loss, wear, and downtime. In this article, you will learn how modern lubrication strategies – from advan...

In the first editions of the Dakar Rally with The Beast, a standard 75W-140 transmission oil was used. This resulted in a rather large amount of wear particles (iron and co...

Using Eurol Assembly Paste HT/FD for drilling equipment in the steel industry prevents carbonization, extends machine lifespan, and reduces downtime, saving over €50,000 an...