Eurol equipas de motos, carros e camiões prontas p...

No Dakar 2026, a Eurol estará presente com uma ampla representação. Com quatro camiões, quatro carros e uma motocicleta, promete ser uma edição emocionante.

9 de maio

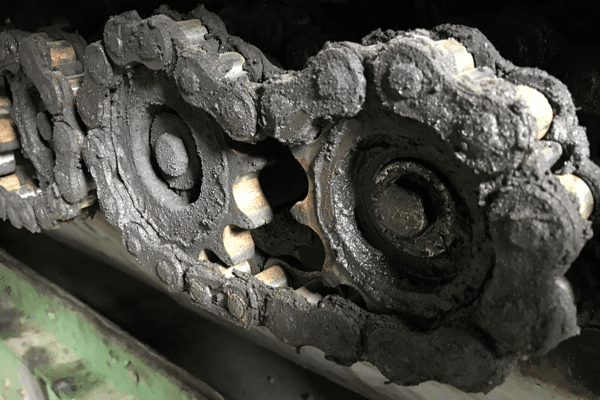

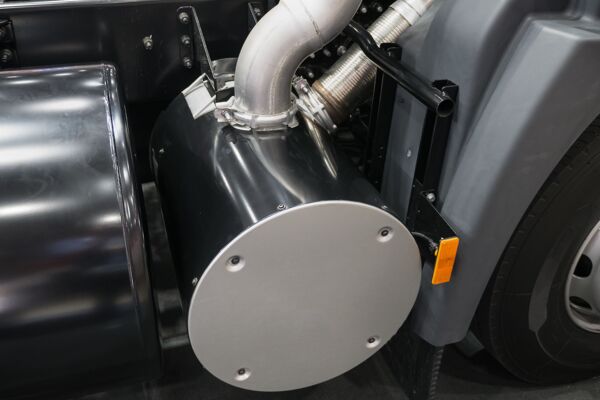

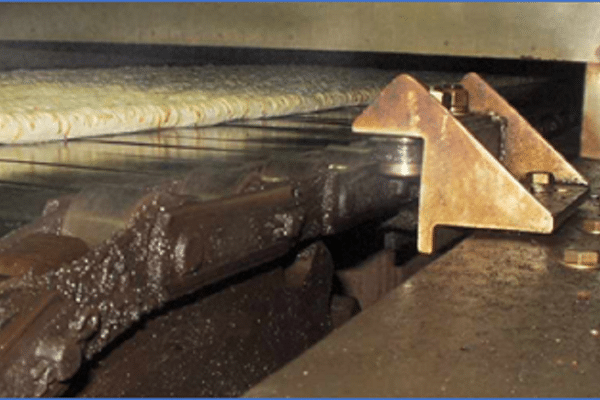

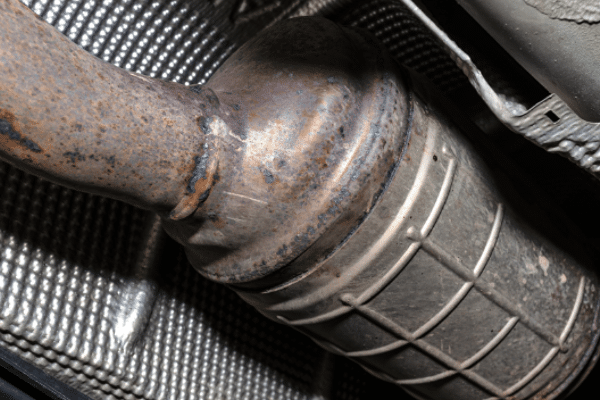

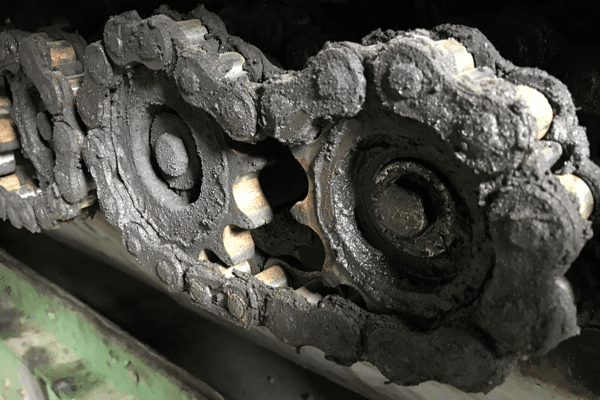

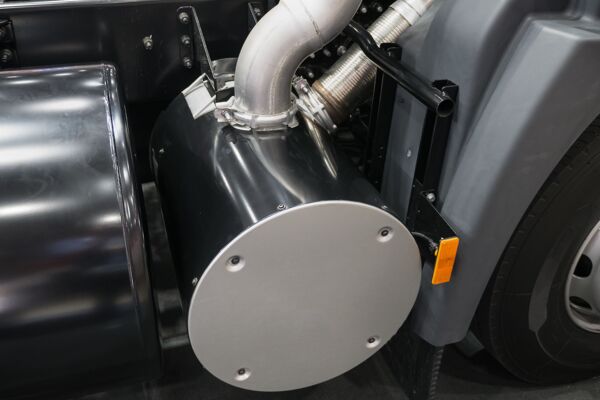

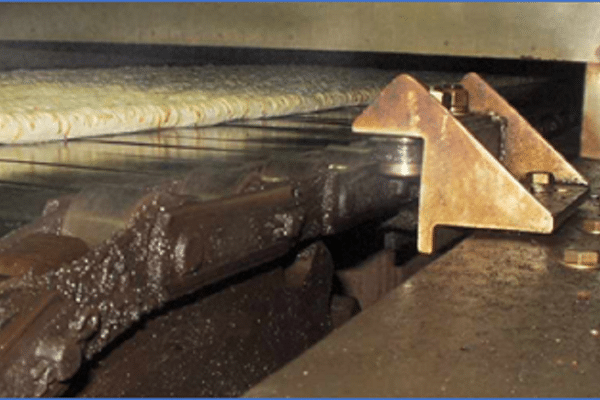

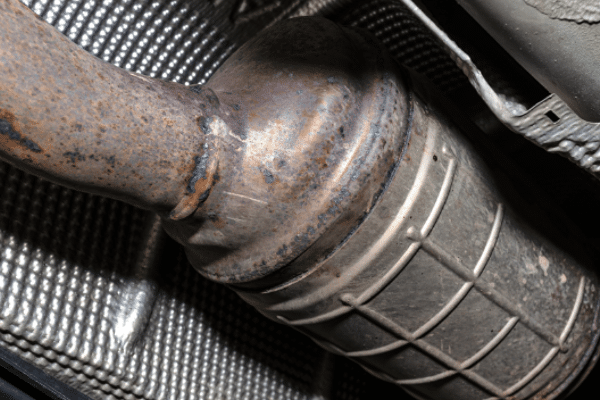

Muitos camiões estão equipados com molas parabólicas, cujas extremidades são lubrificadas para permitir um movimento suave. No entanto, durante o processo de regeneração do filtro de partículas (DPF), o calor irradiado pelo sistema de escape gera temperaturas extremas, provocando o ressequimento e endurecimento da massa lubrificante convencional. O óleo separa-se da massa devido ao calor intenso e acaba por vazar, o que é visível como acúmulo de sujidade e óleo em torno do ponto de articulação. Como consequência, a mola parabólica deixa de se mover livremente, fica presa e quebra com frequência sob cargas de choque.

| Mercado | Camionagem e Transporte |

| Ponto de Lubrificação | Molas Parabólicas |

| Produto | Eurol Grease CS-2/101 |

| Número do Artigo | S005110-180KG |

| Utilização do Produto | Massas Lubrificantes |

Contacte-nos para obter o aconselhamento certo para a sua situação específica.

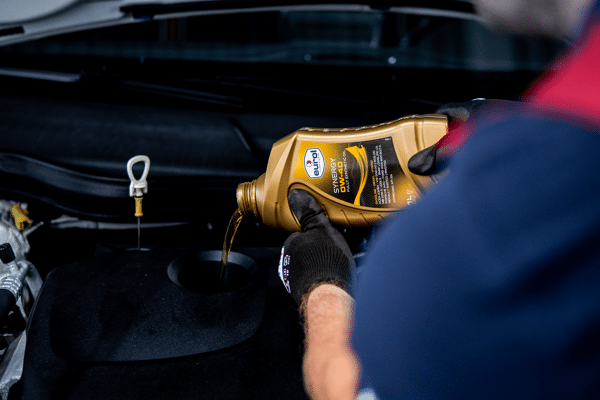

A Eurol Specialty SYNGIS Grease praticamente não liberta óleo, resiste a temperaturas elevadas e não seca. Graças à sua formulação avançada, o ponto de articulação permanece flexível, evitando que as molas parabólicas fiquem bloqueadas e se partam sob cargas de choque. Isto aumenta significativamente a fiabilidade dos camiões e reduz o tempo de inatividade desnecessário.

Muitos camiões estão equipados com molas parabólicas, cujas extremidades são lubrificadas para permitir um movimento suave. No entanto, o calor irradiado gerado durante o processo de regeneração do filtro de partículas (DPF) provoca temperaturas extremas em torno do mecanismo. A massa lubrificante convencional seca, endurece e perde a sua eficácia. O óleo separa-se da massa e escapa devido ao calor excessivo, o que se manifesta como um acúmulo visível de sujidade e óleo no ponto de articulação.

Como resultado, a mola parabólica deixa de funcionar corretamente e parte-se frequentemente sob cargas de choque.

Remko van Keulen, Diretor da Garage Rinsma (Berlikum & Drachten): "Enquanto empresa de transportes, é fácil calcular quanto isto representa em poupança. Valorizamos ter um parceiro que procura ativamente soluções para os nossos problemas. A Eurol dá-nos um ótimo apoio e garante entregas rápidas."

(Situação anterior: O óleo separava-se da massa convencional e secava devido ao calor extremo.)

No Dakar 2026, a Eurol estará presente com uma ampla representação. Com quatro camiões, quatro carros e uma motocicleta, promete ser uma edição emocionante.

A lubrificação e a proteção anticorrosiva melhoradas aumentaram a fiabilidade, reduziram os custos de manutenção e diminuíram o tempo de paragem em aplicações exigentes de ...

Descubra como os motores modernos de dois e quatro tempos evoluem devido às normas de emissões e o que isso significa para a manutenção e escolha do óleo.

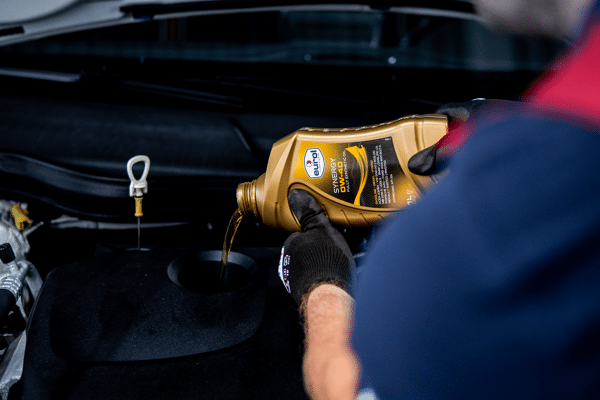

A Eurol introduz o Actence 0W-16, desenvolvido para os mais recentes motores híbridos e a gasolina da Renault e Dacia.

Descubra como o Eurol Grease CS 2 103S evita desgaste grave e tempo de paragem num rolo CNC Haeusler com lubrificação resistente à pressão e comportamento de fluxo estável....

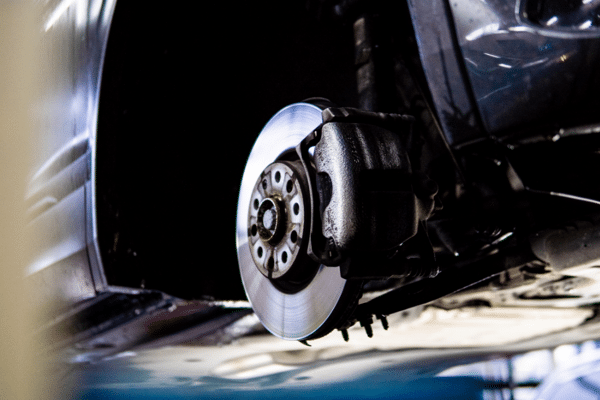

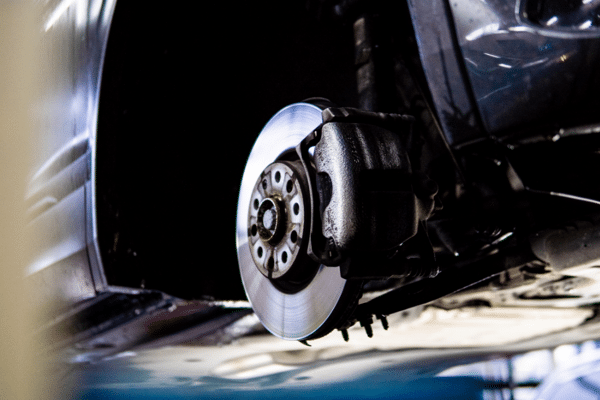

A formação de espuma em sistemas de travagem húmidos pode causar perda de pressão, desgaste e avarias. Saiba como isso ocorre, quais as consequências e como evitá-lo.

Rocco Coronel, júnior da Red Bull, conquista o título do G40 Junior Championship com 11 vitórias e 19 pódios.

Lubrificação confiável de fusos com Eurol Grease CS-2/502-S. Evite desgaste, vazamentos e ressecamento com a proteção duradoura da SYNGIS Technology.

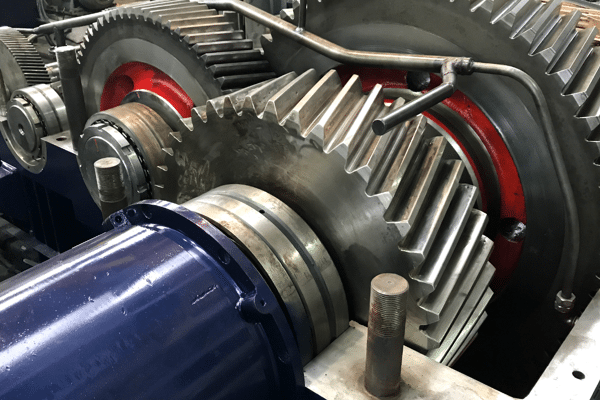

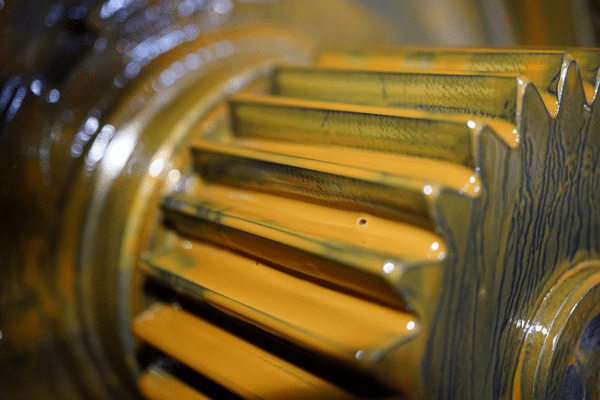

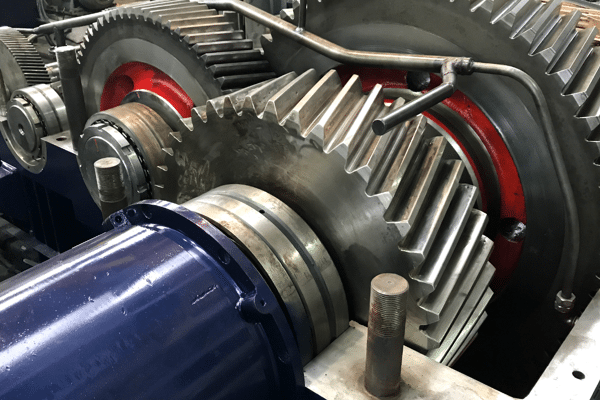

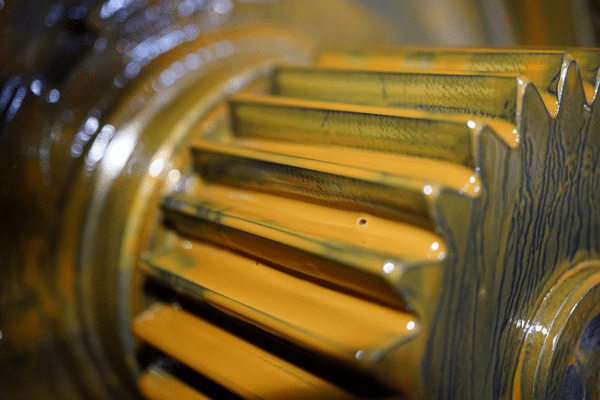

As caixas de engrenagens industriais exigem uma lubrificação fiável para evitar perdas de energia, desgaste e paragens não planeadas. Neste artigo ficará a saber como as es...

A Eurol e a Invicta Racing iniciam uma parceria técnica de F2 com SYNGIS Technology para mais desempenho, eficiência e fiabilidade na Fórmula 2....

O TBN indica a capacidade de neutralização de ácidos de um óleo. Essencial quando se utiliza combustível rico em enxofre e em condições severas, para proteger contra corros...

Ao mudar para Eurol Grease CS-2/103-S, uma empresa de reciclagem de entulho poupou 9 horas de dīkstāve por semana, com arranque automático suave do tambor e sem necessidade...

O fluido de travões é muitas vezes negligenciado, mas crucial para o funcionamento seguro do sistema de travagem. Este artigo explica o que considerar na sua escolha e subs...

A Eurol apoia Ian Olthof, o único motociclista neerlandês no Dakar Rally 2026. Ian confia nos produtos Eurol há muitos anos e representa a marca no rali.

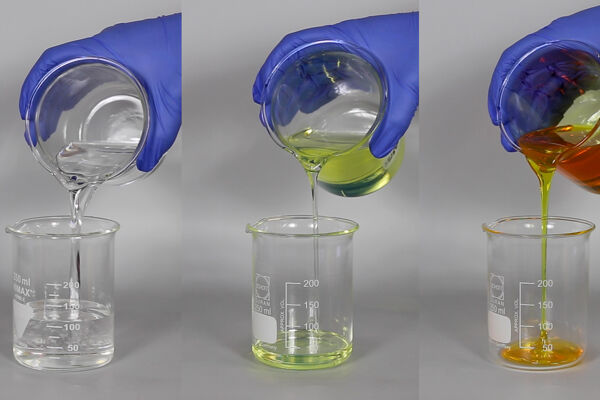

Lubrificação potente e sustentável para aplicações exigentes. Descubra três novos biolubrificantes com SYNGIS Technology que oferecem desempenho máximo em todas as condiçõe...

O Additive-S BIO reduz a temperatura do óleo do Toro Greensmaster, permitindo um corte mais eficiente e sustentável com menos manutenção.

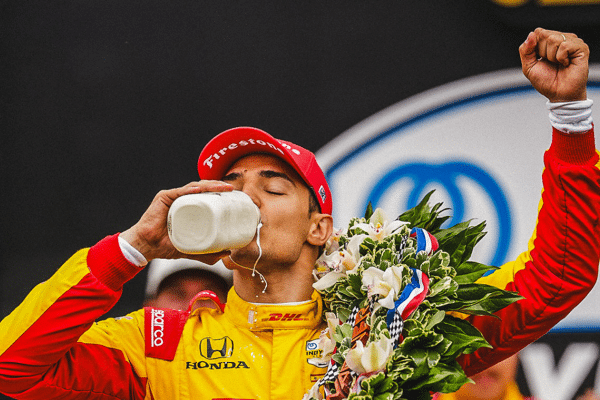

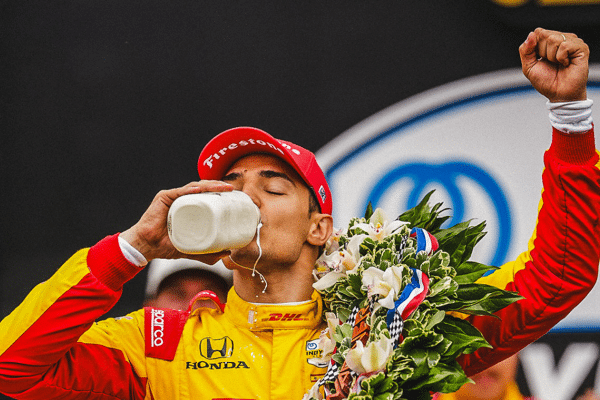

Alex Palou vence a 109.ª edição das 500 Milhas de Indianápolis pela Chip Ganassi Racing. A Eurol, como parceira técnica, deu um contributo essencial para esta conquista.

A má qualidade do gasóleo provoca injetores contaminados e problemas no motor no setor dos transportes. Descubra como uma adição inteligente ao combustível não só reduz as ...

O sal e as cargas pesadas causavam falhas no sistema de carga da Bolk Transport. Com o Eurol Lube CL-F Spray, tudo voltou a funcionar sem problemas.

Evite danos causados pela ferrugem no seu atrelado com a proteção adequada e prolongue a vida útil dos componentes essenciais.

Uma carrinha ligeira com problemas de arranque, perda de potência e aumento do consumo é reparada de forma rápida e especializada na nossa oficina.

A Lama Chemie é o distribuidor com maior crescimento em lubrificantes sustentáveis e Specialty da Eurol em 2024.

A lubrificação especializada prolonga a vida útil e melhora a eficiência das dragas de sucção com funil de arrasto, mesmo sob condições extremas.

A Noroil vence o prémio Eurol Specialty Dealer of the Year 2024 graças ao forte crescimento nas vendas de lubrificantes industriais e fluidos técnicos na Noruega.

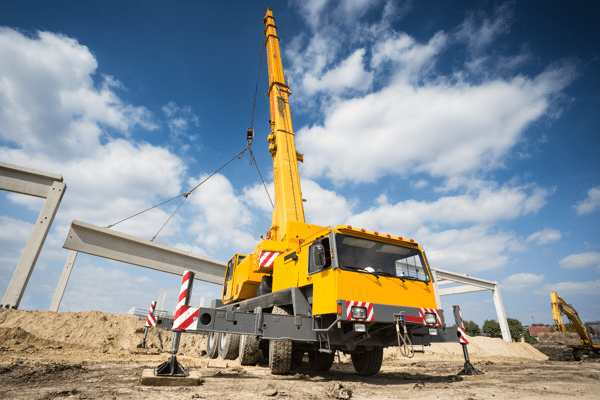

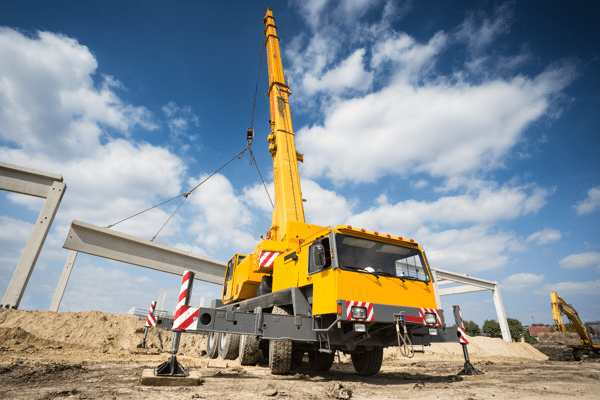

Uma empresa de gruas enfrentava uma corrosão severa nos cabos da lança das suas gruas torre móveis, o que resultava em elevados custos de manutenção e inspeções complexas.

Uma pergunta frequente é se uma corrente deve ser lubrificada com massa lubrificante ou com óleo. Neste artigo, explicamos as diferenças entre ambos e damos conselhos sobre...

Descubra as Eurol Swift Clean HD Wipes para uma limpeza fácil e sem necessidade de água, e o Swift Clean 130 — agora também disponível em embalagem de 20 litros, ideal para...

Uma empresa de táxis, com uma vasta frota de veículos equipados com transmissões automáticas, está a registar um número crescente de queixas sobre o comportamento das mudan...

A aprovação NSF garante a segurança quando o produto é utilizado corretamente, mas não significa que seja "Foodsafe" para contacto direto com alimentos. Compreender as dife...

O Rali Dakar 2025 termina com sucesso para as equipas Eurol: Mitchel van den Brink e Henk Lategan brilham ao garantirem ambos o 2.º lugar na classificação final!

Devido ao downsizing dos motores de combustão interna, um novo fenómeno ocorre com mais frequência: a pré-ignição em baixa rotação (LSPI). O LSPI não é audível nem previsív...

Após cinco duras etapas do Dakar, os participantes da Eurol desfrutam de um merecido dia de descanso. Ambas as equipas viveram sucessos e contratempos.

A Eurol será parceira técnica da Chip Ganassi Racing na temporada de 2025 da INDYCAR SERIES.

A Eurol apoia equipas de topo preparadas para a 47.ª edição do Rali Dakar, que se realiza de 3 a 17 de janeiro de 2025 na Arábia Saudita.

A Eurol lança o Lube PL-S Spray, um lubrificante seco versátil com SYNGIS Technology, agora atualizado e expandido com variantes sustentáveis.

A Eurol reforça a sua parceria com o jovem talento do automobilismo Rocco Coronel, que, além das suas atividades no karting, passa agora também a contar com apoio no Ginett...

As condições extremas na mineração provocam desgaste e tempo de inatividade. A Eurol oferece soluções para melhorar a durabilidade e a eficiência dos equipamentos.

A Eurol apresenta quatro novos produtos, desenvolvidos para diversos tipos de veículos, incluindo automóveis de passageiros modernos, camiões e veículos comerciais ligeiros...

O novo Eurol Screenwash Safe Storage oferece uma solução sem restrições de armazenamento, é seguro de utilizar e garante uma limpeza excelente.

A utilização da Eurol Assembly Paste HT/FD em equipamentos de perfuração na indústria do aço previne a carbonização, prolonga a vida útil das máquinas e reduz o tempo de in...

Estamos a lançar a Carbon Neutral, uma linha de lubrificantes totalmente neutros em CO₂.

Vai de férias de carro? Evite avarias durante a viagem com estas 5 dicas inteligentes para verificar os líquidos do veículo. Assim parte bem preparado e tranquilo rumo ao s...

Apresentamos o Fultrax 75W-90 LS, um óleo de transmissão totalmente sintético com propriedades limited slip.

A utilização de um aditivo de limpeza do motor aquando da mudança de óleo é uma forma simples de prevenir e corrigir a contaminação do motor. Requer pouco tempo e oferece m...

Na produção de pavimentos decorativos pré-fabricados, uma grande escova automática de aço, responsável por manter os moldes limpos, desempenha um papel crucial na garantia ...

Organizações de vários setores estão a considerar os óleos hidráulicos biodegradáveis devido à sustentabilidade e às regulamentações, apesar das dúvidas do passado.

Apresentamos o Transfluid ATF-CVT, uma revolução na tecnologia de fluidos de transmissão. Este é o primeiro óleo de transmissão totalmente sintético adequado tanto para tra...

Apresentamos o Eurol Coolant -36°C G12 EVO, um líquido de refrigeração de última geração desenvolvido com base na tecnologia LOBRID PSi-OAT, especialmente para veículos da ...

O distribuidor Valtec, da Roménia, recebeu o prémio International Eurol Specialty Distributor pelo terceiro ano consecutivo.

No setor do transporte vertical, a lubrificação adequada das partes deslizantes e dos cabos de aço é crucial. Massas lubrificantes desatualizadas podem causar avarias e aum...

Atualmente, existem soluções modernas e especializadas que permitem poupar energia e, ao mesmo tempo, proteger de forma ideal os redutores industriais contra o desgaste e a...

Os códigos de cor dos lubrificantes são uma parte essencial para manter um ambiente de trabalho industrial seguro e eficiente. Saiba mais neste artigo do centro de conhecim...

Reduzir a pegada de CO₂ dos processos industriais está a tornar-se cada vez mais importante. Neste contexto, a poupança de energia desempenha um papel crucial.

A Toyota GAZOO Racing procurava soluções para aumentar a durabilidade dos seus carros de competição e melhorar o desempenho.

A Eurol anuncia o lançamento do Ultrance ST 0W-20, um óleo de motor totalmente sintético e com fórmula avançada para poupança de combustível.

A limpeza das partes deslizantes com limpa travões era um processo intensivo e desfavorável do ponto de vista da saúde ocupacional. O trabalhador tinha de se proteger contr...

A lubrificação das partes deslizantes é frequentemente feita com massa lubrificante padrão. Esta massa, ao contrário do óleo, não é fácil de aplicar com um pincel.

Descubra como um lubrificante inovador transforma a eficiência e a sustentabilidade de equipamentos de transporte e construção rodoviária, como gruas de carga, garras, cami...

Os sistemas hidráulicos destas máquinas de cravação estavam constantemente sujeitos a cargas elevadas, o que resultava numa vida útil reduzida da bomba.

As massas Eurol Specialty CS-2/501 e CS-2/101 contribuíram para uma redução significativa do desgaste nos veios de hélice.

Existem várias razões para desativar temporariamente máquinas. Seja devido aos elevados custos de energia, que levam algumas empresas a abrandar a atividade, ou ao armazena...

Em equipamentos pesados de movimentação de terras, a lubrificação das ligações pino-bucha desempenha um papel crucial na manutenção do desempenho e da vida útil das máquina...

Para os prestadores de serviços agrícolas, a fiabilidade dos seus equipamentos é fundamental para garantir uma operação bem-sucedida e eficiente.

A SMESH desenvolveu um eixo modular elétrico com motor elétrico integrado, conjuntos de embraiagem e sistemas de engrenagens planetárias.

A Eurol apresenta o E Heavy Duty Lube 46 BIO, um óleo hidráulico inovador desenvolvido especialmente para escavadoras elétricas.

Apresentamos o E Heavy Duty, uma nova geração de lubrificantes desenvolvida especialmente para a lubrificação eficiente de máquinas e veículos pesados eletrificados.

Numa fábrica de reciclagem de plástico e gestão de resíduos, surgiu um desafio: falhas repetidas nos rolamentos de trituradores e secadores.

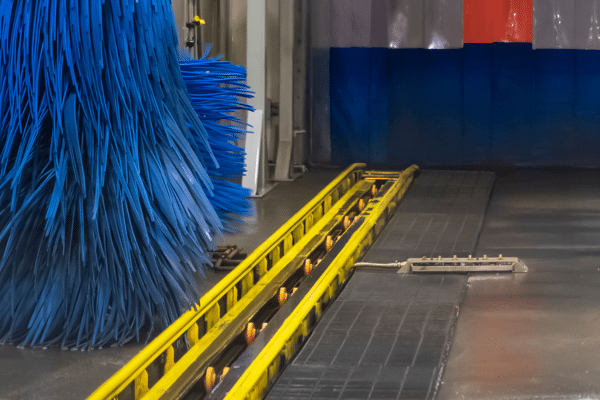

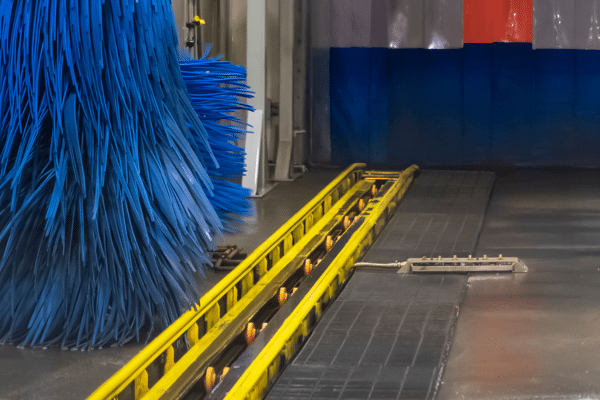

Determinados agentes de limpeza podem danificar as correntes transportadoras e as engrenagens das lavagens automáticas. Estes agentes são tão agressivos que dissolvem os lu...

Numa construção com betão armado e cabos de aço pré-esforçado, utilizam-se “âncoras” — ou grampos de aço — para tensionar e fixar os cabos.

Os rolamentos dos discos de corte do injetor de estrume estão sujeitos a cargas pesadas e entram em contacto com estrume, areia e água. A amónia presente no estrume provoca...

Numa instalação agrícola dedicada ao processamento de feno e palha, os operadores detetaram problemas nas correntes de transporte. As correntes estavam húmidas e pegajosas,...

Recentemente, houve desenvolvimentos significativos em relação à norma de emissões Euro 7 para veículos de passageiros, comerciais ligeiros e comerciais pesados.

Num campo de golfe, são normalmente utilizados cinco tipos de corta-relvas para manter em boas condições os diferentes tipos de relva e terrenos.

Nas operações de manuseamento e transferência de contentores nos portos, é frequentemente utilizado um Reachstacker. Esta máquina está equipada com componentes deslizantes ...

Sob a pressão de exigências cada vez mais rigorosas em matéria de emissões na indústria automóvel, os motores turbo leves, de alta rotação e baixa cilindrada tornaram-se o ...

O impacto da nova norma Euro 7 é significativo. Os fabricantes de camiões e autocarros terão de cumprir regras rigorosas desta norma ambiental para reduzir drasticamente as...

É preciso algum tempo para nos habituarmos à nova temporada da TCR Europe Series. Nesta época, vemos Tom Coronel competir, pela primeira vez, não com o tradicional Audi RS ...

O impacto da nova norma Euro 7 é significativo. Neste artigo técnico, pode ler tudo o que precisa de saber sobre a nova norma Euro 7 e o papel dos lubrificantes.

Um caso prático de um produtor da indústria alimentar que passou a poupar até €20.000 por ano graças à redução da manutenção e do tempo de inatividade, tudo devido aos prod...

Na prática, a lubrificação correta do equipamento agrícola é frequentemente negligenciada. Pontos de lubrificação essenciais não são lubrificados ou são mal lubrificados. O...

Provavelmente já lhe aconteceu: chega a um semáforo e o motor desliga-se. Felizmente, volta a ligar-se automaticamente quando vai arrancar. Irritante ou inteligente? O sist...

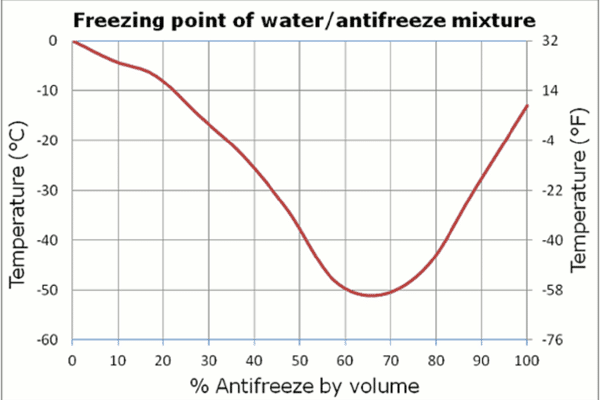

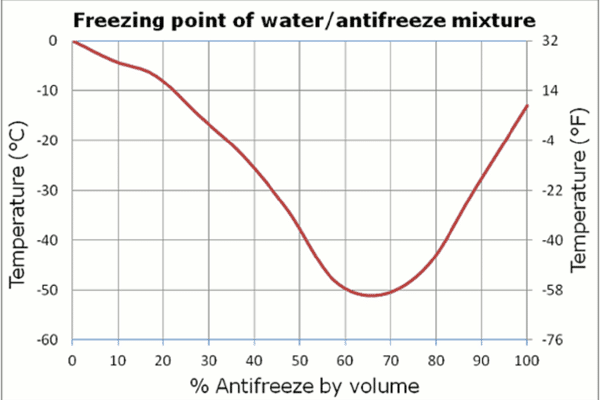

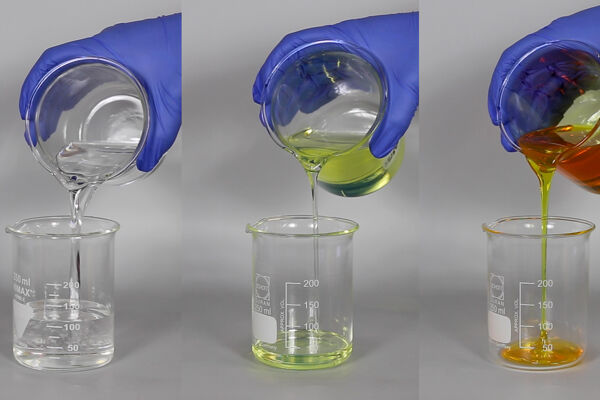

O que faz realmente um líquido de refrigeração? Quais são as diferenças entre as tecnologias existentes e que propriedades oferecem? E por que razão já não é possível escol...

Os camiões estão sujeitos a regulamentações ambientais cada vez mais rigorosas. Não só é necessário reduzir as emissões de substâncias nocivas, como também é essencial dimi...

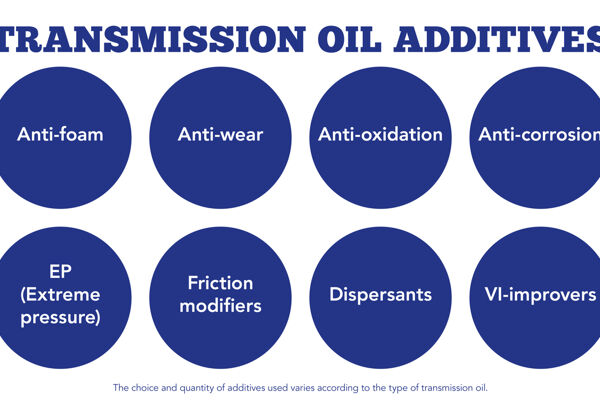

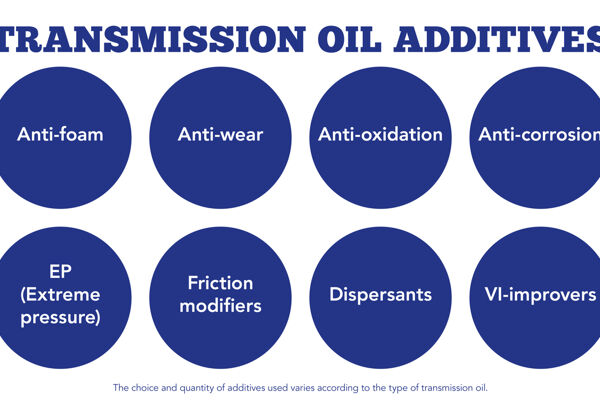

Poupança de combustível, mudanças mais suaves, maior durabilidade e cárteres mais pequenos: estes são os principais fatores que impulsionam a inovação no campo das transmis...

Muitos veículos a diesel modernos utilizam AdBlue para cumprir as normas de emissões. Mas o que é o AdBlue e como funciona? Neste artigo, iremos aprofundar este tema com ma...

Devido à crise do coronavírus, muitos carros ficaram parados durante períodos prolongados. Para evitar problemas e regressar à estrada em segurança, gostaríamos de lhe dar ...

Com a chegada do verão, naturalmente não há nada que queira mais do que voltar à estrada com a sua mota. Quer prepará-la para voltar a andar? Então siga estes 10 passos!

A primavera chegou, por isso está na altura de tirar o seu oldtimer do local onde esteve guardado durante o inverno! Para começar a nova época automóvel de forma segura e t...

Para reduzir as emissões de CO₂, estão a ser implementados, a nível mundial, requisitos cada vez mais rigorosos para os automóveis de passageiros. Para além das inovações n...

Os motores automóveis estão a ser cada vez mais equipados com turbos. Um turbo contém tecnologia avançada e, por isso, é bastante sensível. Problemas no turbo podem afetar ...

Cada vez mais vemos no mercado dispositivos práticos que permitem avaliar a qualidade do fluido de travões. No entanto, dado que é frequentemente questionada a fiabilidade ...

O meio ambiente dita as regras e os fabricantes têm de recorrer às estratégias mais complexas para garantir que os automóveis cumpram as normas de emissões. Isto leva frequ...

Há cerca de uma década, os mecânicos de oficina podiam escolher apenas entre dois tipos de óleo. Hoje, esse número aumentou pelo menos cinco vezes. “Os fabricantes de autom...

As correntes e os rolamentos de um forno de túnel precisam de ser lubrificados. No entanto, isso é frequentemente feito com lubrificantes inadequados para aplicações a alta...

A reciclagem de resíduos exerce muita pressão nos rolamentos. A Heros Sluiskil escolheu uma lubrificação que melhora o desempenho e a fiabilidade.

Trituradores de madeira fazem trabalho pesado. Com os nossos lubrificantes, funcionam mais tempo, com menos paragens, menor consumo e melhor lubrificação dos rolamentos.

Em condições difíceis, a lubrificação certa ajuda os corta-relvas a darem o seu melhor. Na JvESCH, isso reduziu a manutenção e os custos.

Paragens em parquímetros custam dinheiro. Com a lubrificação certa, funcionam de forma fiável e a necessidade de manutenção reduz-se significativamente.

A lubrificação é uma parte essencial da manutenção de máquinas — e isso aplica-se especialmente aos equipamentos de salgação, que garantem a segurança das nossas estradas d...

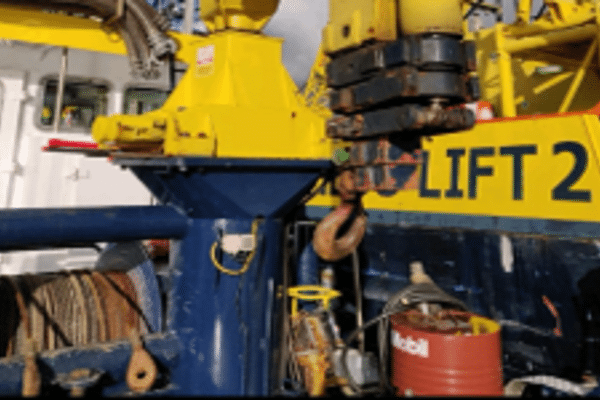

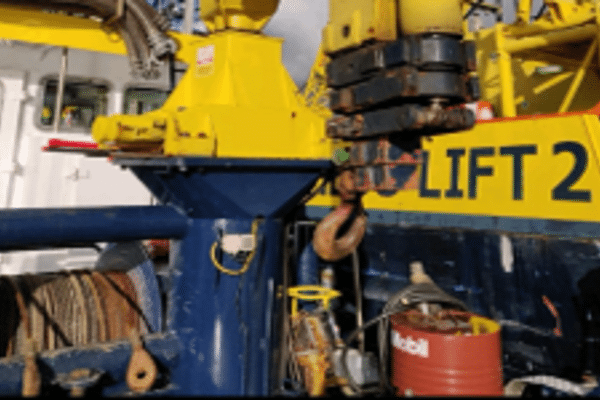

Uma boa lubrificação de máquinas e componentes, como cabos de aço, é essencial — especialmente em equipamentos offshore, onde o sol, os salpicos de água salgada, o vento e ...

Uma boa lubrificação das máquinas é de extrema importância — especialmente para equipamentos utilizados no setor offshore, onde as condições ambientais e climatéricas têm u...

A caixa de velocidades sequencial está equipada com acoplamentos tipo dog clutch que funcionam como sincronizadores. Estes componentes estão frequentemente sujeitos a um de...

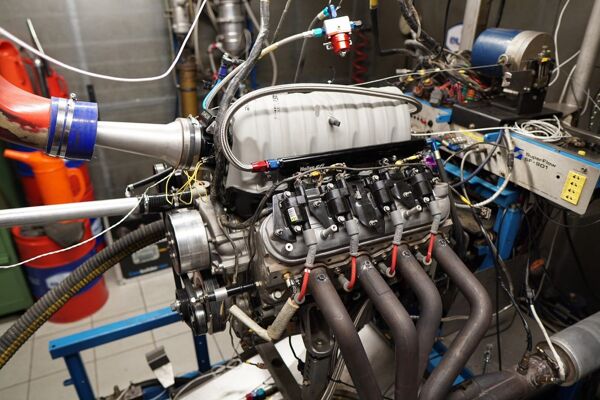

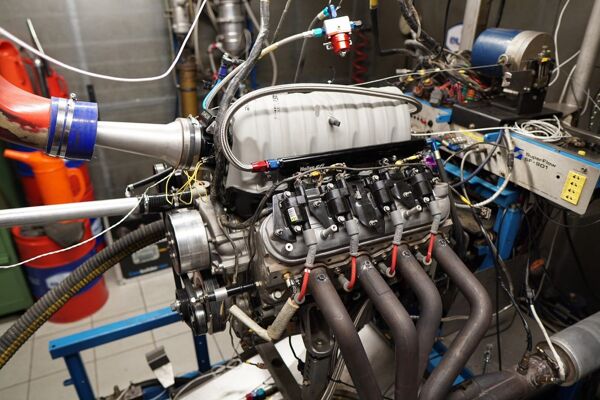

O motor foi desenvolvido para uso em competição. Todos os motores são selados, o que significa que os únicos benefícios de desempenho possíveis podem ser obtidos através da...

Bob de Jong é um conhecido piloto de ralis neerlandês e também Campeão Nacional de Ralis. Está sempre em busca de melhor desempenho e menor fricção para o carro, recorrendo...

Bob de Jong é um conhecido piloto de ralis neerlandês e também Campeão Nacional de Ralis. Está sempre à procura de melhor desempenho e menor fricção para o seu Hyundai i20 ...

A Porsche utiliza torque vectoring ativo em curva, aplicando os travões nas rodas interiores para aumentar a velocidade em curva. Durante corridas em pista, a aplicação dos...

Os Porsche em pista competem com óleo de motor padrão com especificação Porsche A40. No entanto, os proprietários notaram uma pressão de óleo mais baixa quando o motor atin...

Os motores estavam afinados para funcionar com Mobil1 0W-30, um lubrificante difícil de encontrar. A preparadora neerlandesa APP Racing Engines trabalha com um motor NASCAR...

Desgaste excessivo dos componentes e utilização de demasiados tipos diferentes de óleo. Além disso, a vida útil do óleo tinha de ser de, pelo menos, 6 etapas do Rali Dakar....

O fluido original da transmissão automática ZF não foi desenvolvido para condições de competição. A proteção a altas temperaturas não é ideal. Além disso, o desgaste era re...

Durante o Rali Dakar, o motor funciona a plena carga durante horas, o que faz com que as temperaturas aumentem. Nessas condições, o óleo do motor é frequentemente contamina...

Sobreaquecimento do diferencial num BMW E46 M3 GTR. O diferencial não pode ser preenchido com 75W-140 devido à presença de um radiador de óleo. Por isso, é necessário um ól...

Uma quinta roda normalmente dura tanto quanto a vida útil de um camião, mas no caso da Bolk Transport, é frequentemente necessário instalar uma quinta roda extra.

Problemas de fluidez ao utilizar uma massa lubrificante fluida. Além disso, existia o risco de aplicação incorreta entre diferentes partes do camião, como a caixa de transf...

A Van den Boogaard é especializada em transporte, salvamento pesado e aluguer de gruas. O equipamento, incluindo gruas montadas em camiões, deve estar disponível dia e noit...

A caixa de velocidades operava com uma temperatura do cárter superior a 130 °C durante uma corrida de endurance de 12 horas, com o óleo de transmissão utilizado na altura. ...

Os óleos de transmissão têm de proteger todas as partes lubrificadas durante todo o Rali Dakar, com o mínimo de fricção e desgaste. Os produtos utilizados anteriormente era...

Na Riwald Recycling em Almelo, trabalha-se intensivamente com garras montadas em gruas. As gruas e garras estão em rotação constante ao longo do dia, sendo exercida uma for...

A Polskamp Meat Industrie é especializada na separação da carne de frango dos ossos. As linhas de produção funcionam 24 horas por dia para transformar várias partes do fran...

Massa é massa, certo? "Nem por isso — os nossos lubrificantes têm uma composição completamente diferente dos lubrificantes convencionais." A revista automóvel AMT visitou r...

Desde 2011, os automóveis de passageiros a gasóleo devem estar equipados de fábrica com um filtro de partículas para cumprir os requisitos de emissões europeus. Torna-se, p...

O motor utilizava todos os anos um óleo 10W-60 padrão. Durante o rali Dakar, registou-se desgaste no motor devido à entrada de areia. Também ocorreram quedas ocasionais na ...

Um conversor de binário transfere a potência do motor para a transmissão. Quando está destravado, desliza constantemente, o que provoca fricção e calor. O Beast 2019 utiliz...

No processamento de túlipas, a continuidade é essencial. A lubrificação certa das correntes ajuda a Triflor na estufa e nos processos de exportação.

Mario Kress, Diretor Geral da MKR Technology, é o desenvolvedor e construtor do Renault Truck C460 Hybrid Edition da Riwald Rallysport. Este será o primeiro camião híbrido ...

São solicitados produtos Eurol específicos para diferentes marcas e modelos de automóveis. Isto levanta desafios tanto logísticos como administrativos, o que exige uma gest...

No Dakar 2026, a Eurol estará presente com uma ampla representação. Com quatro camiões, quatro carros e uma motocicleta, promete ser uma edição emocionante.

A lubrificação e a proteção anticorrosiva melhoradas aumentaram a fiabilidade, reduziram os custos de manutenção e diminuíram o tempo de paragem em aplicações exigentes de ...

Descubra como os motores modernos de dois e quatro tempos evoluem devido às normas de emissões e o que isso significa para a manutenção e escolha do óleo.

A Eurol introduz o Actence 0W-16, desenvolvido para os mais recentes motores híbridos e a gasolina da Renault e Dacia.

Descubra como o Eurol Grease CS 2 103S evita desgaste grave e tempo de paragem num rolo CNC Haeusler com lubrificação resistente à pressão e comportamento de fluxo estável....

A formação de espuma em sistemas de travagem húmidos pode causar perda de pressão, desgaste e avarias. Saiba como isso ocorre, quais as consequências e como evitá-lo.

Rocco Coronel, júnior da Red Bull, conquista o título do G40 Junior Championship com 11 vitórias e 19 pódios.

Lubrificação confiável de fusos com Eurol Grease CS-2/502-S. Evite desgaste, vazamentos e ressecamento com a proteção duradoura da SYNGIS Technology.

As caixas de engrenagens industriais exigem uma lubrificação fiável para evitar perdas de energia, desgaste e paragens não planeadas. Neste artigo ficará a saber como as es...

A Eurol e a Invicta Racing iniciam uma parceria técnica de F2 com SYNGIS Technology para mais desempenho, eficiência e fiabilidade na Fórmula 2....

O TBN indica a capacidade de neutralização de ácidos de um óleo. Essencial quando se utiliza combustível rico em enxofre e em condições severas, para proteger contra corros...

Ao mudar para Eurol Grease CS-2/103-S, uma empresa de reciclagem de entulho poupou 9 horas de dīkstāve por semana, com arranque automático suave do tambor e sem necessidade...

O fluido de travões é muitas vezes negligenciado, mas crucial para o funcionamento seguro do sistema de travagem. Este artigo explica o que considerar na sua escolha e subs...

A Eurol apoia Ian Olthof, o único motociclista neerlandês no Dakar Rally 2026. Ian confia nos produtos Eurol há muitos anos e representa a marca no rali.

Lubrificação potente e sustentável para aplicações exigentes. Descubra três novos biolubrificantes com SYNGIS Technology que oferecem desempenho máximo em todas as condiçõe...

O Additive-S BIO reduz a temperatura do óleo do Toro Greensmaster, permitindo um corte mais eficiente e sustentável com menos manutenção.

Alex Palou vence a 109.ª edição das 500 Milhas de Indianápolis pela Chip Ganassi Racing. A Eurol, como parceira técnica, deu um contributo essencial para esta conquista.

A má qualidade do gasóleo provoca injetores contaminados e problemas no motor no setor dos transportes. Descubra como uma adição inteligente ao combustível não só reduz as ...

O sal e as cargas pesadas causavam falhas no sistema de carga da Bolk Transport. Com o Eurol Lube CL-F Spray, tudo voltou a funcionar sem problemas.

Evite danos causados pela ferrugem no seu atrelado com a proteção adequada e prolongue a vida útil dos componentes essenciais.

Uma carrinha ligeira com problemas de arranque, perda de potência e aumento do consumo é reparada de forma rápida e especializada na nossa oficina.

A Lama Chemie é o distribuidor com maior crescimento em lubrificantes sustentáveis e Specialty da Eurol em 2024.

A lubrificação especializada prolonga a vida útil e melhora a eficiência das dragas de sucção com funil de arrasto, mesmo sob condições extremas.

A Noroil vence o prémio Eurol Specialty Dealer of the Year 2024 graças ao forte crescimento nas vendas de lubrificantes industriais e fluidos técnicos na Noruega.

Uma empresa de gruas enfrentava uma corrosão severa nos cabos da lança das suas gruas torre móveis, o que resultava em elevados custos de manutenção e inspeções complexas.

Uma pergunta frequente é se uma corrente deve ser lubrificada com massa lubrificante ou com óleo. Neste artigo, explicamos as diferenças entre ambos e damos conselhos sobre...

Descubra as Eurol Swift Clean HD Wipes para uma limpeza fácil e sem necessidade de água, e o Swift Clean 130 — agora também disponível em embalagem de 20 litros, ideal para...

Uma empresa de táxis, com uma vasta frota de veículos equipados com transmissões automáticas, está a registar um número crescente de queixas sobre o comportamento das mudan...

A aprovação NSF garante a segurança quando o produto é utilizado corretamente, mas não significa que seja "Foodsafe" para contacto direto com alimentos. Compreender as dife...

O Rali Dakar 2025 termina com sucesso para as equipas Eurol: Mitchel van den Brink e Henk Lategan brilham ao garantirem ambos o 2.º lugar na classificação final!

Devido ao downsizing dos motores de combustão interna, um novo fenómeno ocorre com mais frequência: a pré-ignição em baixa rotação (LSPI). O LSPI não é audível nem previsív...

Após cinco duras etapas do Dakar, os participantes da Eurol desfrutam de um merecido dia de descanso. Ambas as equipas viveram sucessos e contratempos.

A Eurol será parceira técnica da Chip Ganassi Racing na temporada de 2025 da INDYCAR SERIES.

A Eurol apoia equipas de topo preparadas para a 47.ª edição do Rali Dakar, que se realiza de 3 a 17 de janeiro de 2025 na Arábia Saudita.

A Eurol lança o Lube PL-S Spray, um lubrificante seco versátil com SYNGIS Technology, agora atualizado e expandido com variantes sustentáveis.

A Eurol reforça a sua parceria com o jovem talento do automobilismo Rocco Coronel, que, além das suas atividades no karting, passa agora também a contar com apoio no Ginett...

As condições extremas na mineração provocam desgaste e tempo de inatividade. A Eurol oferece soluções para melhorar a durabilidade e a eficiência dos equipamentos.

A Eurol apresenta quatro novos produtos, desenvolvidos para diversos tipos de veículos, incluindo automóveis de passageiros modernos, camiões e veículos comerciais ligeiros...

O novo Eurol Screenwash Safe Storage oferece uma solução sem restrições de armazenamento, é seguro de utilizar e garante uma limpeza excelente.

A utilização da Eurol Assembly Paste HT/FD em equipamentos de perfuração na indústria do aço previne a carbonização, prolonga a vida útil das máquinas e reduz o tempo de in...

Estamos a lançar a Carbon Neutral, uma linha de lubrificantes totalmente neutros em CO₂.

Vai de férias de carro? Evite avarias durante a viagem com estas 5 dicas inteligentes para verificar os líquidos do veículo. Assim parte bem preparado e tranquilo rumo ao s...

Apresentamos o Fultrax 75W-90 LS, um óleo de transmissão totalmente sintético com propriedades limited slip.

A utilização de um aditivo de limpeza do motor aquando da mudança de óleo é uma forma simples de prevenir e corrigir a contaminação do motor. Requer pouco tempo e oferece m...

Na produção de pavimentos decorativos pré-fabricados, uma grande escova automática de aço, responsável por manter os moldes limpos, desempenha um papel crucial na garantia ...

Organizações de vários setores estão a considerar os óleos hidráulicos biodegradáveis devido à sustentabilidade e às regulamentações, apesar das dúvidas do passado.

Apresentamos o Transfluid ATF-CVT, uma revolução na tecnologia de fluidos de transmissão. Este é o primeiro óleo de transmissão totalmente sintético adequado tanto para tra...

Apresentamos o Eurol Coolant -36°C G12 EVO, um líquido de refrigeração de última geração desenvolvido com base na tecnologia LOBRID PSi-OAT, especialmente para veículos da ...

O distribuidor Valtec, da Roménia, recebeu o prémio International Eurol Specialty Distributor pelo terceiro ano consecutivo.

No setor do transporte vertical, a lubrificação adequada das partes deslizantes e dos cabos de aço é crucial. Massas lubrificantes desatualizadas podem causar avarias e aum...

Atualmente, existem soluções modernas e especializadas que permitem poupar energia e, ao mesmo tempo, proteger de forma ideal os redutores industriais contra o desgaste e a...

Os códigos de cor dos lubrificantes são uma parte essencial para manter um ambiente de trabalho industrial seguro e eficiente. Saiba mais neste artigo do centro de conhecim...

Reduzir a pegada de CO₂ dos processos industriais está a tornar-se cada vez mais importante. Neste contexto, a poupança de energia desempenha um papel crucial.

A Toyota GAZOO Racing procurava soluções para aumentar a durabilidade dos seus carros de competição e melhorar o desempenho.

A Eurol anuncia o lançamento do Ultrance ST 0W-20, um óleo de motor totalmente sintético e com fórmula avançada para poupança de combustível.

A limpeza das partes deslizantes com limpa travões era um processo intensivo e desfavorável do ponto de vista da saúde ocupacional. O trabalhador tinha de se proteger contr...

A lubrificação das partes deslizantes é frequentemente feita com massa lubrificante padrão. Esta massa, ao contrário do óleo, não é fácil de aplicar com um pincel.

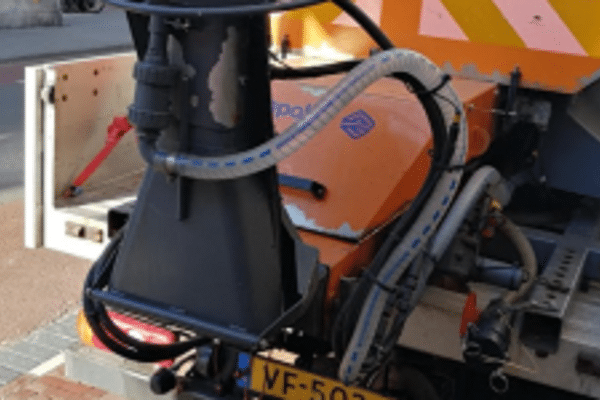

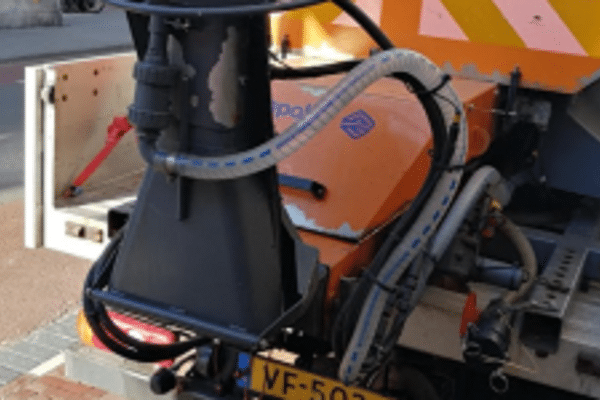

Descubra como um lubrificante inovador transforma a eficiência e a sustentabilidade de equipamentos de transporte e construção rodoviária, como gruas de carga, garras, cami...

Os sistemas hidráulicos destas máquinas de cravação estavam constantemente sujeitos a cargas elevadas, o que resultava numa vida útil reduzida da bomba.

As massas Eurol Specialty CS-2/501 e CS-2/101 contribuíram para uma redução significativa do desgaste nos veios de hélice.

Existem várias razões para desativar temporariamente máquinas. Seja devido aos elevados custos de energia, que levam algumas empresas a abrandar a atividade, ou ao armazena...

Em equipamentos pesados de movimentação de terras, a lubrificação das ligações pino-bucha desempenha um papel crucial na manutenção do desempenho e da vida útil das máquina...

Para os prestadores de serviços agrícolas, a fiabilidade dos seus equipamentos é fundamental para garantir uma operação bem-sucedida e eficiente.

A SMESH desenvolveu um eixo modular elétrico com motor elétrico integrado, conjuntos de embraiagem e sistemas de engrenagens planetárias.

A Eurol apresenta o E Heavy Duty Lube 46 BIO, um óleo hidráulico inovador desenvolvido especialmente para escavadoras elétricas.

Apresentamos o E Heavy Duty, uma nova geração de lubrificantes desenvolvida especialmente para a lubrificação eficiente de máquinas e veículos pesados eletrificados.

Numa fábrica de reciclagem de plástico e gestão de resíduos, surgiu um desafio: falhas repetidas nos rolamentos de trituradores e secadores.

Determinados agentes de limpeza podem danificar as correntes transportadoras e as engrenagens das lavagens automáticas. Estes agentes são tão agressivos que dissolvem os lu...

Numa construção com betão armado e cabos de aço pré-esforçado, utilizam-se “âncoras” — ou grampos de aço — para tensionar e fixar os cabos.

Os rolamentos dos discos de corte do injetor de estrume estão sujeitos a cargas pesadas e entram em contacto com estrume, areia e água. A amónia presente no estrume provoca...

Numa instalação agrícola dedicada ao processamento de feno e palha, os operadores detetaram problemas nas correntes de transporte. As correntes estavam húmidas e pegajosas,...

Recentemente, houve desenvolvimentos significativos em relação à norma de emissões Euro 7 para veículos de passageiros, comerciais ligeiros e comerciais pesados.

Num campo de golfe, são normalmente utilizados cinco tipos de corta-relvas para manter em boas condições os diferentes tipos de relva e terrenos.

Nas operações de manuseamento e transferência de contentores nos portos, é frequentemente utilizado um Reachstacker. Esta máquina está equipada com componentes deslizantes ...

Sob a pressão de exigências cada vez mais rigorosas em matéria de emissões na indústria automóvel, os motores turbo leves, de alta rotação e baixa cilindrada tornaram-se o ...

O impacto da nova norma Euro 7 é significativo. Os fabricantes de camiões e autocarros terão de cumprir regras rigorosas desta norma ambiental para reduzir drasticamente as...

É preciso algum tempo para nos habituarmos à nova temporada da TCR Europe Series. Nesta época, vemos Tom Coronel competir, pela primeira vez, não com o tradicional Audi RS ...

O impacto da nova norma Euro 7 é significativo. Neste artigo técnico, pode ler tudo o que precisa de saber sobre a nova norma Euro 7 e o papel dos lubrificantes.

Um caso prático de um produtor da indústria alimentar que passou a poupar até €20.000 por ano graças à redução da manutenção e do tempo de inatividade, tudo devido aos prod...

Na prática, a lubrificação correta do equipamento agrícola é frequentemente negligenciada. Pontos de lubrificação essenciais não são lubrificados ou são mal lubrificados. O...

Provavelmente já lhe aconteceu: chega a um semáforo e o motor desliga-se. Felizmente, volta a ligar-se automaticamente quando vai arrancar. Irritante ou inteligente? O sist...

O que faz realmente um líquido de refrigeração? Quais são as diferenças entre as tecnologias existentes e que propriedades oferecem? E por que razão já não é possível escol...

Os camiões estão sujeitos a regulamentações ambientais cada vez mais rigorosas. Não só é necessário reduzir as emissões de substâncias nocivas, como também é essencial dimi...

Poupança de combustível, mudanças mais suaves, maior durabilidade e cárteres mais pequenos: estes são os principais fatores que impulsionam a inovação no campo das transmis...

Muitos veículos a diesel modernos utilizam AdBlue para cumprir as normas de emissões. Mas o que é o AdBlue e como funciona? Neste artigo, iremos aprofundar este tema com ma...

Devido à crise do coronavírus, muitos carros ficaram parados durante períodos prolongados. Para evitar problemas e regressar à estrada em segurança, gostaríamos de lhe dar ...

Com a chegada do verão, naturalmente não há nada que queira mais do que voltar à estrada com a sua mota. Quer prepará-la para voltar a andar? Então siga estes 10 passos!

A primavera chegou, por isso está na altura de tirar o seu oldtimer do local onde esteve guardado durante o inverno! Para começar a nova época automóvel de forma segura e t...

Para reduzir as emissões de CO₂, estão a ser implementados, a nível mundial, requisitos cada vez mais rigorosos para os automóveis de passageiros. Para além das inovações n...

Os motores automóveis estão a ser cada vez mais equipados com turbos. Um turbo contém tecnologia avançada e, por isso, é bastante sensível. Problemas no turbo podem afetar ...

Cada vez mais vemos no mercado dispositivos práticos que permitem avaliar a qualidade do fluido de travões. No entanto, dado que é frequentemente questionada a fiabilidade ...

O meio ambiente dita as regras e os fabricantes têm de recorrer às estratégias mais complexas para garantir que os automóveis cumpram as normas de emissões. Isto leva frequ...

Há cerca de uma década, os mecânicos de oficina podiam escolher apenas entre dois tipos de óleo. Hoje, esse número aumentou pelo menos cinco vezes. “Os fabricantes de autom...

As correntes e os rolamentos de um forno de túnel precisam de ser lubrificados. No entanto, isso é frequentemente feito com lubrificantes inadequados para aplicações a alta...

A reciclagem de resíduos exerce muita pressão nos rolamentos. A Heros Sluiskil escolheu uma lubrificação que melhora o desempenho e a fiabilidade.

Trituradores de madeira fazem trabalho pesado. Com os nossos lubrificantes, funcionam mais tempo, com menos paragens, menor consumo e melhor lubrificação dos rolamentos.

Em condições difíceis, a lubrificação certa ajuda os corta-relvas a darem o seu melhor. Na JvESCH, isso reduziu a manutenção e os custos.

Paragens em parquímetros custam dinheiro. Com a lubrificação certa, funcionam de forma fiável e a necessidade de manutenção reduz-se significativamente.

A lubrificação é uma parte essencial da manutenção de máquinas — e isso aplica-se especialmente aos equipamentos de salgação, que garantem a segurança das nossas estradas d...

Uma boa lubrificação de máquinas e componentes, como cabos de aço, é essencial — especialmente em equipamentos offshore, onde o sol, os salpicos de água salgada, o vento e ...

Uma boa lubrificação das máquinas é de extrema importância — especialmente para equipamentos utilizados no setor offshore, onde as condições ambientais e climatéricas têm u...

A caixa de velocidades sequencial está equipada com acoplamentos tipo dog clutch que funcionam como sincronizadores. Estes componentes estão frequentemente sujeitos a um de...

O motor foi desenvolvido para uso em competição. Todos os motores são selados, o que significa que os únicos benefícios de desempenho possíveis podem ser obtidos através da...

Bob de Jong é um conhecido piloto de ralis neerlandês e também Campeão Nacional de Ralis. Está sempre em busca de melhor desempenho e menor fricção para o carro, recorrendo...

Bob de Jong é um conhecido piloto de ralis neerlandês e também Campeão Nacional de Ralis. Está sempre à procura de melhor desempenho e menor fricção para o seu Hyundai i20 ...

A Porsche utiliza torque vectoring ativo em curva, aplicando os travões nas rodas interiores para aumentar a velocidade em curva. Durante corridas em pista, a aplicação dos...

Os Porsche em pista competem com óleo de motor padrão com especificação Porsche A40. No entanto, os proprietários notaram uma pressão de óleo mais baixa quando o motor atin...

Os motores estavam afinados para funcionar com Mobil1 0W-30, um lubrificante difícil de encontrar. A preparadora neerlandesa APP Racing Engines trabalha com um motor NASCAR...

Desgaste excessivo dos componentes e utilização de demasiados tipos diferentes de óleo. Além disso, a vida útil do óleo tinha de ser de, pelo menos, 6 etapas do Rali Dakar....

O fluido original da transmissão automática ZF não foi desenvolvido para condições de competição. A proteção a altas temperaturas não é ideal. Além disso, o desgaste era re...

Durante o Rali Dakar, o motor funciona a plena carga durante horas, o que faz com que as temperaturas aumentem. Nessas condições, o óleo do motor é frequentemente contamina...

Sobreaquecimento do diferencial num BMW E46 M3 GTR. O diferencial não pode ser preenchido com 75W-140 devido à presença de um radiador de óleo. Por isso, é necessário um ól...

Uma quinta roda normalmente dura tanto quanto a vida útil de um camião, mas no caso da Bolk Transport, é frequentemente necessário instalar uma quinta roda extra.

Problemas de fluidez ao utilizar uma massa lubrificante fluida. Além disso, existia o risco de aplicação incorreta entre diferentes partes do camião, como a caixa de transf...

A Van den Boogaard é especializada em transporte, salvamento pesado e aluguer de gruas. O equipamento, incluindo gruas montadas em camiões, deve estar disponível dia e noit...

A caixa de velocidades operava com uma temperatura do cárter superior a 130 °C durante uma corrida de endurance de 12 horas, com o óleo de transmissão utilizado na altura. ...

Os óleos de transmissão têm de proteger todas as partes lubrificadas durante todo o Rali Dakar, com o mínimo de fricção e desgaste. Os produtos utilizados anteriormente era...

Na Riwald Recycling em Almelo, trabalha-se intensivamente com garras montadas em gruas. As gruas e garras estão em rotação constante ao longo do dia, sendo exercida uma for...

A Polskamp Meat Industrie é especializada na separação da carne de frango dos ossos. As linhas de produção funcionam 24 horas por dia para transformar várias partes do fran...

Massa é massa, certo? "Nem por isso — os nossos lubrificantes têm uma composição completamente diferente dos lubrificantes convencionais." A revista automóvel AMT visitou r...

Desde 2011, os automóveis de passageiros a gasóleo devem estar equipados de fábrica com um filtro de partículas para cumprir os requisitos de emissões europeus. Torna-se, p...

O motor utilizava todos os anos um óleo 10W-60 padrão. Durante o rali Dakar, registou-se desgaste no motor devido à entrada de areia. Também ocorreram quedas ocasionais na ...

Um conversor de binário transfere a potência do motor para a transmissão. Quando está destravado, desliza constantemente, o que provoca fricção e calor. O Beast 2019 utiliz...

No processamento de túlipas, a continuidade é essencial. A lubrificação certa das correntes ajuda a Triflor na estufa e nos processos de exportação.

Mario Kress, Diretor Geral da MKR Technology, é o desenvolvedor e construtor do Renault Truck C460 Hybrid Edition da Riwald Rallysport. Este será o primeiro camião híbrido ...

São solicitados produtos Eurol específicos para diferentes marcas e modelos de automóveis. Isto levanta desafios tanto logísticos como administrativos, o que exige uma gest...