La estrategia de refrigeración de los motores Volv...

Por qué el calor local es decisivo para la estrategia de refrigeración de los motores Volvo heavy duty y qué significa esto para la selección del refrigerante y el mantenim...

9 de mayo

Reducción de costes de mantenimiento: 50 %

Reducción del tiempo de inactividad: 50 %

Aumento de la capacidad de producción: 10 %

Ahorro económico: entre 10.000 € y 20.000 €

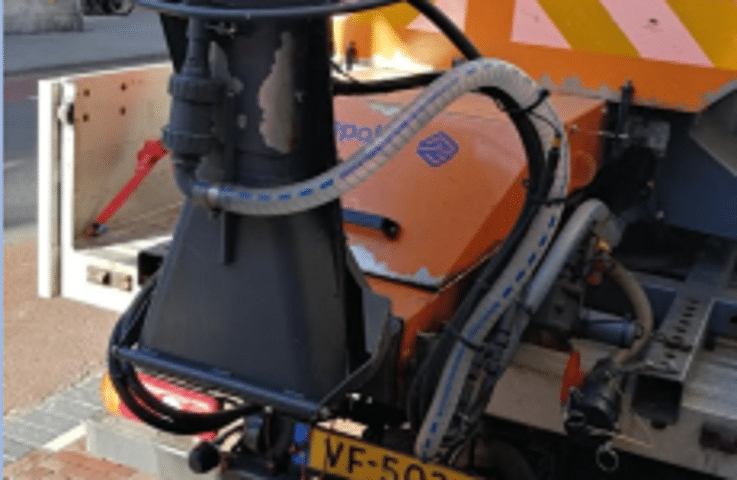

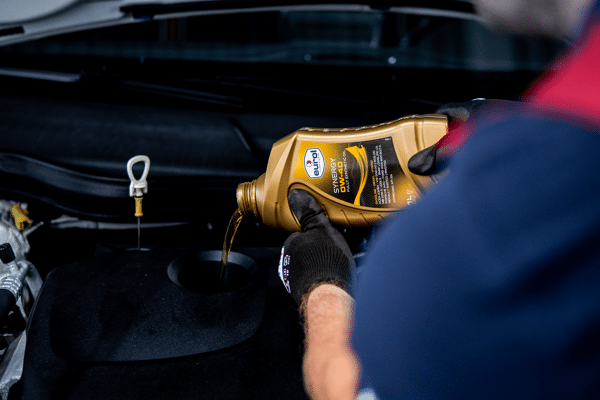

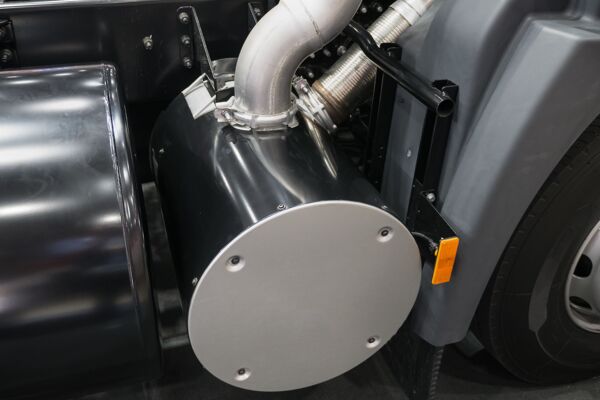

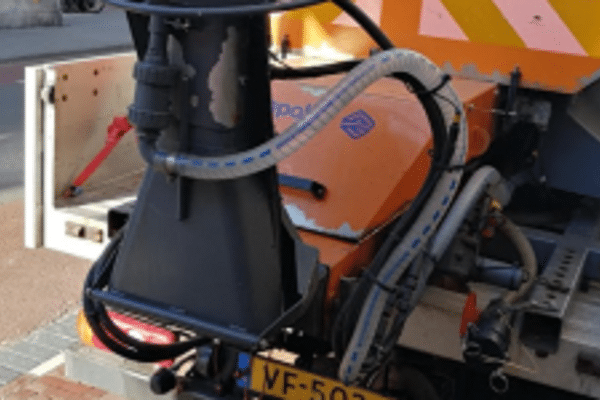

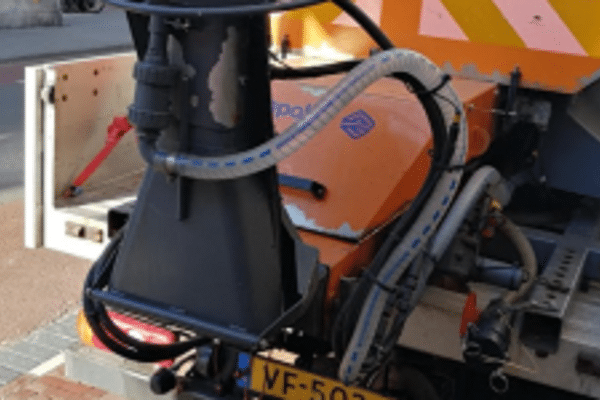

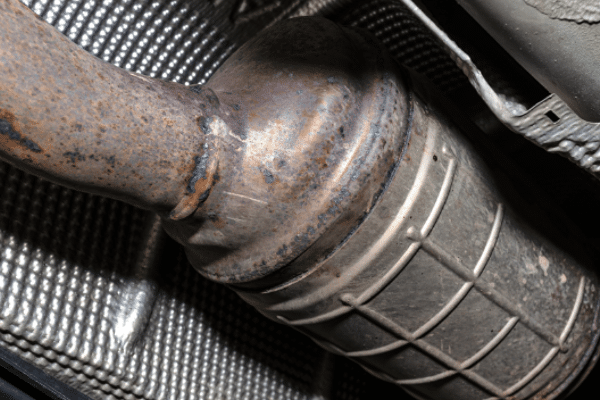

La lubricación es una parte esencial del mantenimiento de la maquinaria. Esto aplica especialmente a los equipos de deshielo que deben mantener seguras nuestras carreteras durante los meses de invierno. En este estudio de caso analizamos el efecto de nuestros lubricantes Specialty en estas máquinas de deshielo. Mostramos cómo los productos Eurol Specialty contribuyen a reducir el trabajo de mantenimiento y el tiempo de inactividad.

| Mercado | Infraestructura |

| Punto de Lubricación | Rodamientos de rueda |

| Producto | Eurol Lube PL Spray Eurol Grease CS2/502-S spray |

| Número de Artículo | S009101AER S005121AER |

| Uso del Producto | Grasas lubricantes |

Con los Eurol Grease CS2/502-S spray y Eurol Lube PL Spray, se lubricaron las partes expuestas y se protegieron contra la corrosión. Con los cartuchos de grasa Eurol Grease CS2 / 502-S se lubricaron los rodamientos de las ruedas, lo que resultó en un desgaste y una corrosión prácticamente inexistentes. Se requiere menos mantenimiento, lo que reduce el tiempo de inactividad.

Consumo de productos: aproximadamente una caja (12 unidades) de sprays y una caja de cartuchos de grasa al año.

Por qué el calor local es decisivo para la estrategia de refrigeración de los motores Volvo heavy duty y qué significa esto para la selección del refrigerante y el mantenim...

Los equipos Eurol vivieron un Rally Dakar 2026 lleno de acontecimientos con siete victorias de etapa, un podio para Mitchel van den Brink y sólidos debuts de Kay Huzink e I...

El joven talento mostró su mejor versión durante la primera semana del Dakar 2026, con sólidas actuaciones en camiones, coches y motos por parte de los participantes de Eur...

En el Dakar 2026, Eurol estará presente con una representación amplia. Con cuatro camiones, cuatro coches y una motocicleta, promete ser una edición emocionante.

La lubricación y la protección anticorrosiva mejoradas aumentaron la fiabilidad, redujeron los costes de mantenimiento y disminuyeron el tiempo de inactividad en aplicacion...

Descubra cómo los motores modernos de dos y cuatro tiempos evolucionan por las normas de emisiones y qué implica para el mantenimiento y la elección del aceite.

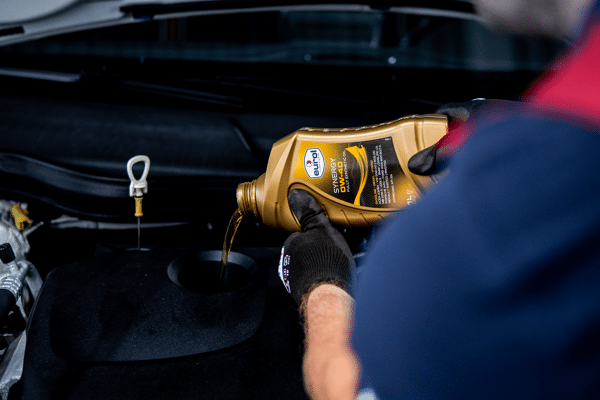

Eurol introduce el Actence 0W-16, desarrollado para los motores híbridos y de gasolina más recientes de Renault y Dacia.

Descubra cómo Eurol Grease CS 2 103S evita el desgaste grave y el tiempo de inactividad en un rodillo CNC Haeusler gracias a una lubricación resistente a la presión y un co...

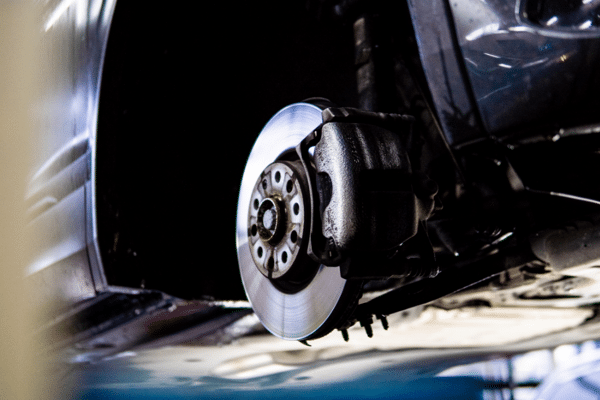

La formación de espuma en los sistemas de frenos húmedos puede provocar pérdida de presión, desgaste y fallos. Lea cómo se produce, cuáles son sus consecuencias y cómo evit...

Rocco Coronel, piloto júnior de Red Bull, se corona campeón del G40 Junior Championship con 11 victorias y 19 podios.

Lubricación fiable de husillos con Eurol Grease CS-2/502-S. Evite el desgaste, las fugas y el secado con la protección duradera de SYNGIS Technology.

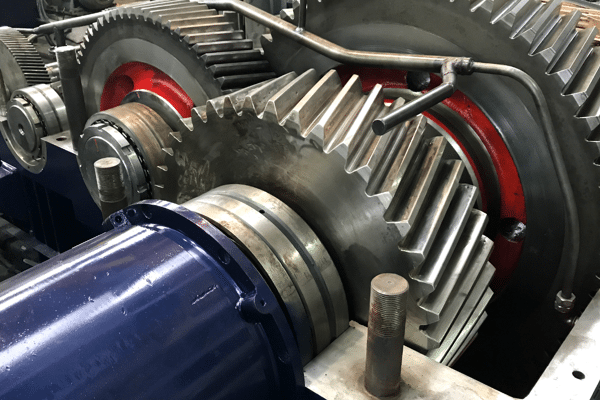

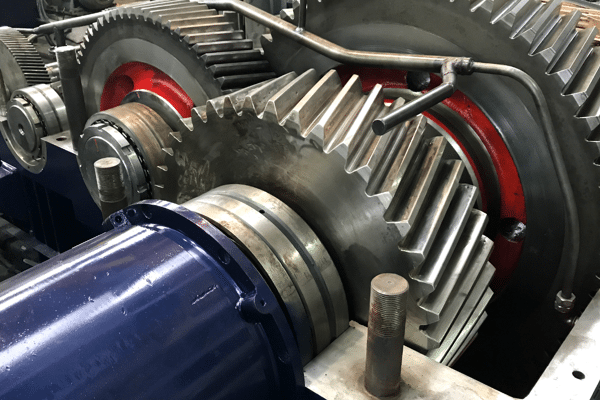

Las cajas de engranajes industriales requieren una lubricación fiable para evitar pérdidas de energía, desgaste y paradas. En este artículo descubrirá cómo las estrategias ...

Eurol e Invicta Racing inician una asociación técnica de F2 con SYNGIS Technology para mayor rendimiento, eficiencia y fiabilidad en la Fórmula 2.

El TBN indica la capacidad del aceite para neutralizar ácidos. Es esencial cuando se utiliza combustible con alto contenido de azufre y en condiciones de alta exigencia, pa...

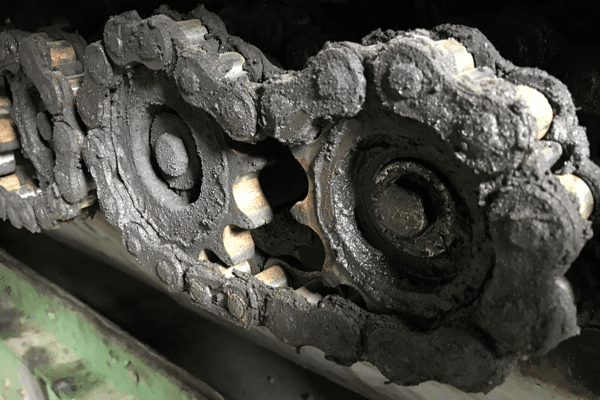

Al cambiar a Eurol Grease CS-2/103-S, una empresa de reciclaje de escombros ahorra 9 horas de dīkstāve por semana, con un arranque automático fluido del tambor y sin necesi...

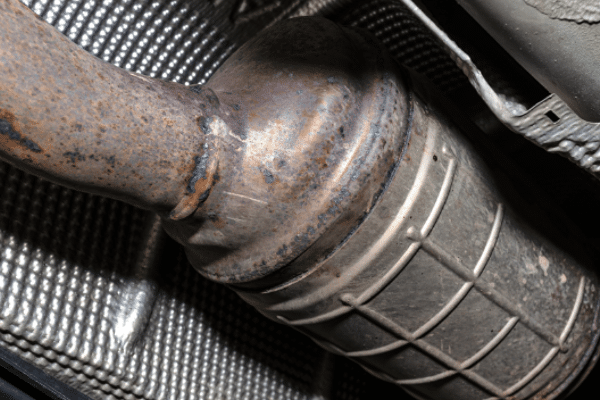

El líquido de frenos suele pasarse por alto, pero es esencial para que el sistema de frenado funcione con seguridad. En este artículo le explicamos qué debe tener en cuenta...

Eurol apoya a Ian Olthof, el único piloto neerlandés en moto en el Rally Dakar 2026. Ian confía en los productos Eurol desde hace años y representa a la marca en el rally.

Lubricación potente y sostenible para aplicaciones de uso intensivo. Descubra tres nuevos biolubricantes con SYNGIS Technology que ofrecen el máximo rendimiento en cualquie...

Additive-S BIO reduce la temperatura del aceite en la Toro Greensmaster, lo que permite un corte más eficiente y sostenible con menos mantenimiento.

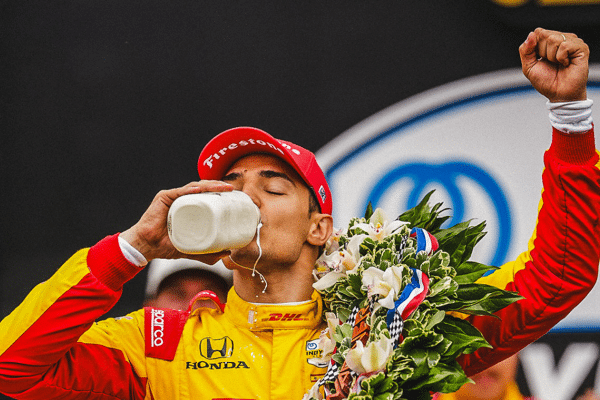

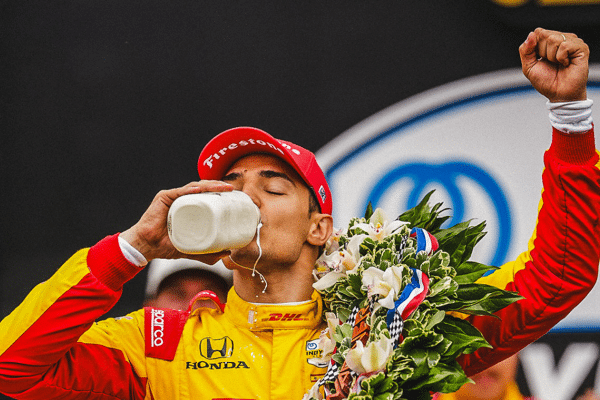

Álex Palou gana la 109ª edición de las 500 Millas de Indianápolis para Chip Ganassi Racing. Eurol, como socio técnico, ha contribuido de manera esencial a este logro.

La baja calidad del diésel provoca inyectores contaminados y problemas en el motor en el sector del transporte. Descubre cómo una solución inteligente añadida al combustibl...

La sal y las cargas pesadas provocaban fallos en el sistema de carga de Bolk Transport. Con Eurol Lube CL-F Spray, todo vuelve a funcionar sin problemas.

Evita los daños por óxido en el remolque de tu embarcación con la protección adecuada y prolonga la vida útil de los componentes vitales.

Una furgoneta pequeña con problemas de arranque, pérdida de potencia y mayor consumo es diagnosticada y reparada con profesionalidad en nuestro taller.

Lama Chemie es el distribuidor de lubricantes sostenibles y especiales de Eurol con mayor crecimiento en 2024.

La lubricación especializada prolonga la vida útil y mejora la eficiencia de las dragas de tolva de succión por arrastre en condiciones extremas.

Noroil gana el premio Eurol Specialty Dealer of the Year 2024 gracias a su sólido crecimiento en lubricantes industriales y fluidos técnicos en Noruega.

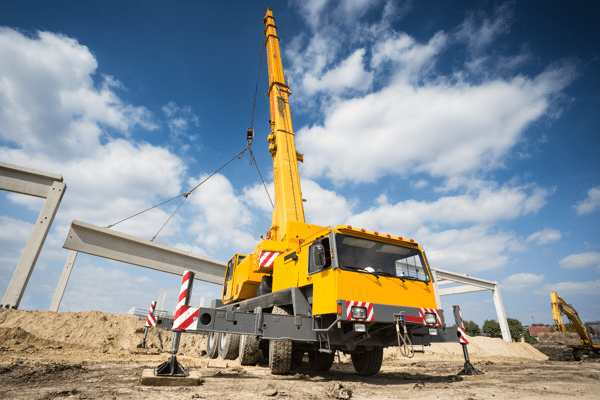

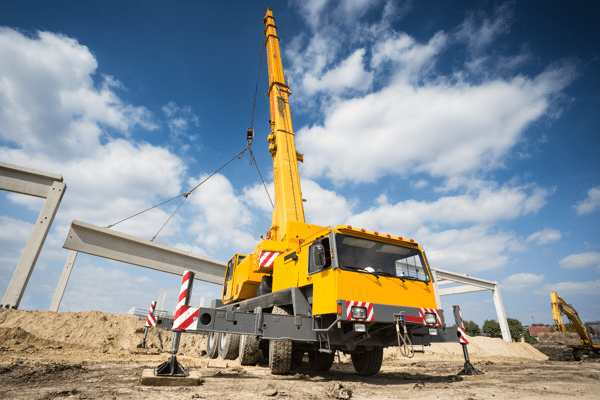

Una empresa de grúas se enfrentaba a una fuerte corrosión en los cables del plumín de sus grúas torre móviles, lo que provocaba elevados costes de mantenimiento e inspeccio...

¿Lubricar una cadena con grasa o con aceite? En este artículo descubrirás las diferencias y recibirás asesoramiento experto sobre el mejor método de lubricación para un ren...

Descubre las Eurol Swift Clean HD Wipes para una limpieza sin esfuerzo y sin agua, y el Swift Clean 130, ahora también disponible en un bidón de 20 L para uso frecuente.

Una empresa de taxis, con una amplia flota de vehículos equipados con transmisiones automáticas, está recibiendo cada vez más quejas sobre el comportamiento del cambio en a...

Foodsafe y certificación NSF: lo que debes saber sobre productos de limpieza seguros

El Rally Dakar 2025 concluye con éxito para los equipos Eurol: Mitchel van den Brink y Henk Lategan brillan al conseguir ambos el segundo puesto en la clasificación final.

Debido a la reducción del tamaño de los motores de combustión interna, un nuevo fenómeno ocurre con más frecuencia: la preignición a baja velocidad (LSPI). La LSPI no se pu...

Tras cinco agotadoras etapas del Dakar, los participantes de Eurol disfrutan de un merecido día de descanso. Tanto Toyota GAZOO Racing South Africa como Eurol Rallysport ha...

Eurol se asociará con Chip Ganassi Racing como socio técnico para la temporada 2025 de la INDYCAR SERIES.

Eurol apoya a equipos de primer nivel preparados para la 47ª edición del Rally Dakar, que se celebrará del 3 al 17 de enero de 2025 en Arabia Saudí.

Eurol lanza el spray Lube PL-S, un lubricante seco versátil con SYNGIS Technology, ahora actualizado y ampliado con variantes sostenibles.

Eurol se enorgullece de anunciar que su colaboración con Rocco Coronel se intensifica. El apoyo se amplía a todas las actividades de competición de este joven talento neerl...

Extreme conditions in mining cause wear and downtime. Eurol offers solutions to improve the lifespan and efficiency of machinery.

Eurol presenta cuatro nuevos productos, desarrollados para diversos vehículos, incluidos turismos modernos, camiones y vehículos comerciales ligeros.

El nuevo Eurol Screenwash Safe Storage ofrece una solución sin restricciones de almacenamiento, es seguro de usar y garantiza una limpieza excelente.

Sustituir la grasa lubricante por Eurol Assembly Paste HT/FD permite un ahorro de al menos 50.000 € al año.

Estamos presentando ‘Carbon Neutral’, una línea de lubricantes totalmente CO₂-neutros.

Gaat u met de auto op vakantie? Voorkom pech onderweg met deze 5 slimme tips voor het controleren van vloeistoffen. Zo vertrekt u zorgeloos én goed voorbereid richting uw b...

Presentamos el Fultrax 75W-90 LS, un aceite de transmisión totalmente sintético con propiedades limited slip.

Utilizar un aditivo de enjuague al cambiar el aceite del motor es una forma sencilla de prevenir y eliminar la contaminación del motor. Requiere poco tiempo y ofrece múltip...

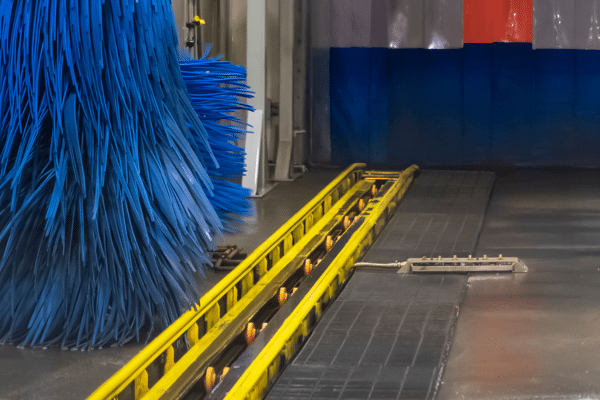

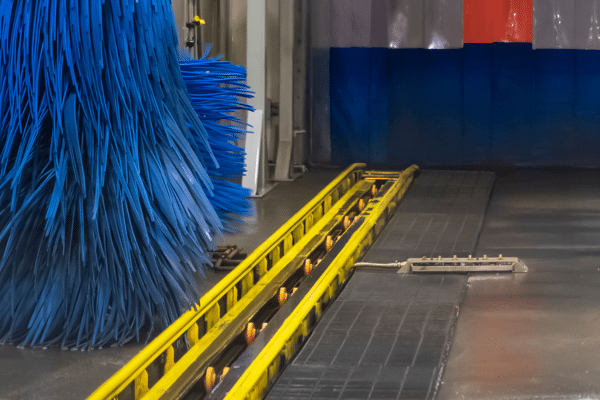

En la producción de adoquines decorativos prefabricados, un gran cepillo de acero automático que mantiene limpios los moldes desempeña un papel crucial para garantizar la c...

Organizaciones de diversos sectores están considerando aceites hidráulicos biodegradables por motivos de sostenibilidad y normativas, a pesar de dudas anteriores; las varia...

Presentamos el Transfluid ATF-CVT, una revolución en la tecnología de fluidos para transmisiones. Es el primer aceite de transmisión totalmente sintético adecuado tanto par...

Presentamos el Eurol Coolant -36 °C G12 EVO, un refrigerante de última generación desarrollado con tecnología LOBRID PSi-OAT, específicamente para los vehículos de nueva ge...

El distribuidor Valtec, de Rumanía, ha recibido por tercer año consecutivo el premio International Eurol Specialty Distributor.

En el sector del transporte vertical, la lubricación adecuada de las piezas deslizantes y los cables de acero es crucial. Las grasas obsoletas pueden provocar fallos y un m...

Hoy en día, existen soluciones especializadas modernas que permiten ahorrar energía y, al mismo tiempo, proteger de forma óptima las cajas de engranajes industriales contra...

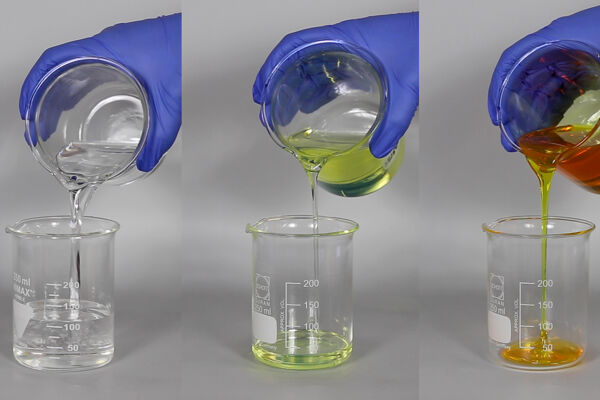

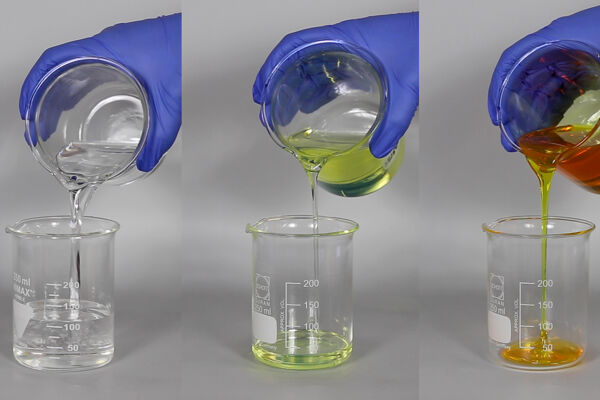

Los códigos de color en los lubricantes son una parte fundamental para mantener un entorno de trabajo industrial seguro y eficiente. Lee más en este artículo informativo.

Reducir la huella de CO₂ de los procesos industriales es cada vez más importante. En este contexto, el ahorro energético desempeña un papel crucial.

Toyota GAZOO Racing buscaba soluciones para aumentar la durabilidad en sus coches de competición y mejorar el rendimiento.

Eurol anuncia la introducción del aceite de motor Ultrance ST 0W-20, una fórmula avanzada, totalmente sintética y ahorradora de combustible.

La limpieza de las piezas deslizantes con limpiador de frenos era un proceso laborioso y desfavorable desde el punto de vista de la salud laboral. El operario tenía que pro...

La lubricación de las piezas deslizantes suele realizarse con grasa estándar. Esta grasa, a diferencia del aceite, no se aplica fácilmente con un pincel.

Descubre cómo un lubricante innovador transforma la eficiencia y la sostenibilidad de los equipos de transporte y construcción vial, como grúas de carga, pinzas hidráulicas...

Los sistemas hidráulicos de estas máquinas hincadoras de pilotes estaban constantemente sometidos a una carga intensa, lo que resultaba en una vida útil reducida de la bomb...

Eurol Specialty CS-2/501 y CS-2/101 han contribuido a una reducción significativa del desgaste en los ejes de hélice.

Existen diversas razones para desactivar temporalmente las máquinas. Ya sea debido a los altos costos energéticos que obligan a algunas empresas a actuar con cautela, o al ...

Para los contratistas agrícolas, la fiabilidad de su maquinaria es fundamental para una operación exitosa y eficiente.

En los equipos de movimiento de tierras de servicio pesado, la lubricación de las conexiones pasador-casquillo desempeña un papel crucial en el mantenimiento del rendimient...

SMESH ha desarrollado un eje eléctrico modular con E-motor integrado, paquetes de embrague y sistemas de engranajes planetarios.

Eurol presenta E Heavy Duty Lube 46 BIO, un aceite hidráulico revolucionario desarrollado especialmente para excavadoras eléctricas.

Presentamos E Heavy Duty, una nueva generación de lubricantes desarrollados especialmente para la lubricación eficiente de maquinaria y vehículos eléctricos pesados.

En una planta de reciclaje de plástico y gestión de residuos, se enfrentaron a un desafío: fallos repetitivos en los rodamientos de trituradoras y secadoras.

Ciertos agentes de limpieza pueden dañar las cadenas transportadoras y los engranajes del túnel de lavado. Estos productos son tan agresivos que disuelven los lubricantes e...

En una obra que involucra hormigón armado y cables de acero pretensado, se utilizan “anclajes” o abrazaderas de acero para tensar y sujetar los cables.

Los rodamientos de los discos de corte del inyector de estiércol están sometidos a cargas pesadas y entran en contacto con estiércol, arena y agua. El amoníaco presente en ...

En una instalación agrícola dedicada al procesamiento de heno y paja, los operarios detectaron problemas en las cadenas de transporte. Las cadenas estaban húmedas y pegajos...

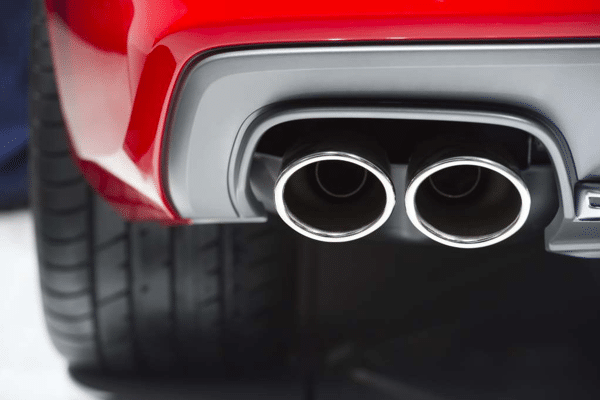

Recientemente, ha habido desarrollos significativos con respecto a las normas de emisiones Euro 7 para turismos, vehículos comerciales ligeros y vehículos industriales pesa...

En un campo de golf, normalmente se utilizan cinco tipos de cortacéspedes para mantener en buen estado los distintos tipos de césped y terrenos.

En las operaciones de manipulación y transferencia de contenedores en los puertos, se utiliza frecuentemente un Reachstacker. Esta máquina está equipada con componentes des...

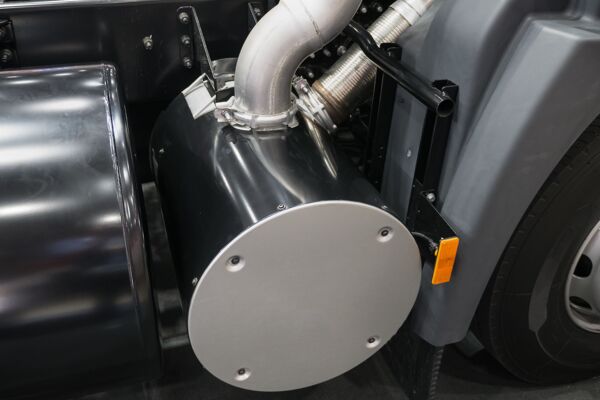

El impacto de la nueva norma Euro 7 es significativo. Los fabricantes de camiones y autobuses deben cumplir con estrictas reglas dentro de esta norma medioambiental para re...

El impacto de la nueva norma Euro 7 es significativo. En este artículo técnico podrás leer todo lo que necesitas saber sobre la nueva norma Euro 7 y el papel de los lubrica...

Bajo la presión de las normativas de emisiones cada vez más estrictas en la industria automotriz, los motores turbo ligeros, de alto régimen y baja cilindrada se han conver...

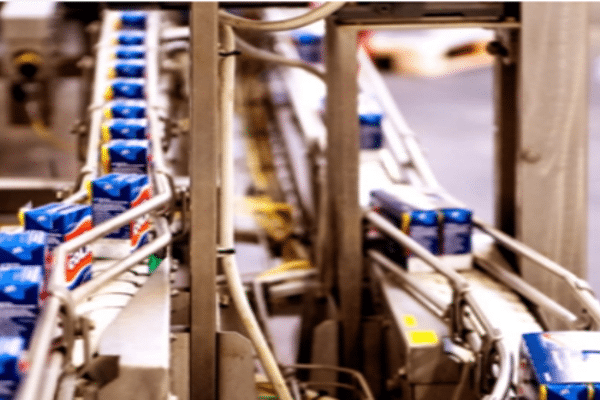

Un caso práctico de un productor en la industria alimentaria que ha llegado a ahorrar hasta 20.000 € al año gracias a una reducción en el mantenimiento y el tiempo de inact...

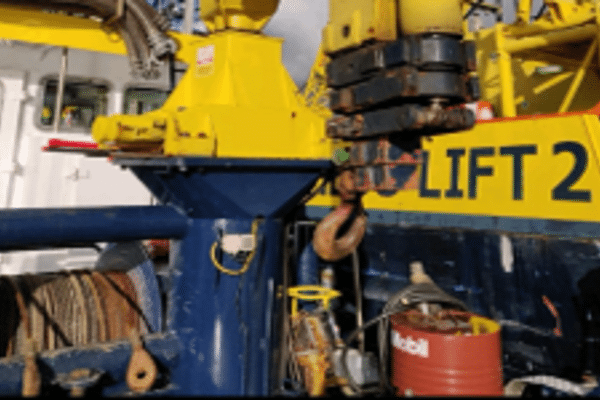

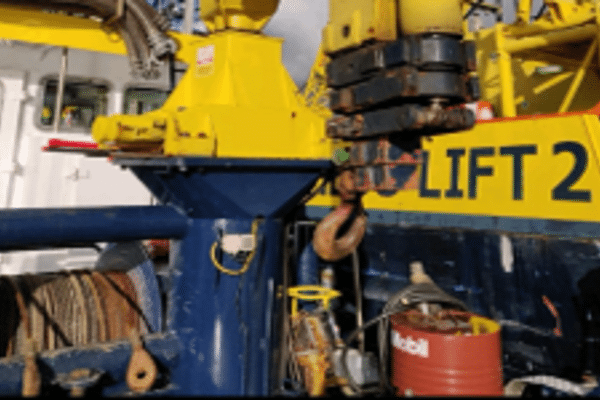

Van den Boogaard is specialized in transport, heavy salvage, and crane rental. The equipment, including truck mounted cranes, must be available day and night under all circ...

In this case study we will discuss the effect of our specialty lubricants on these de-icing machines. We show how our Eurol Specialty products contribute to less maintenanc...

En la práctica, la lubricación adecuada del equipo agrícola a menudo se descuida. Puntos de engrase esenciales no se lubrican o no se lubrican correctamente. El resultado e...

Seguramente te resulta familiar la siguiente situación: llegas a un semáforo y el motor se apaga. Afortunadamente, se vuelve a encender cuando quieres continuar. ¿Irritante...

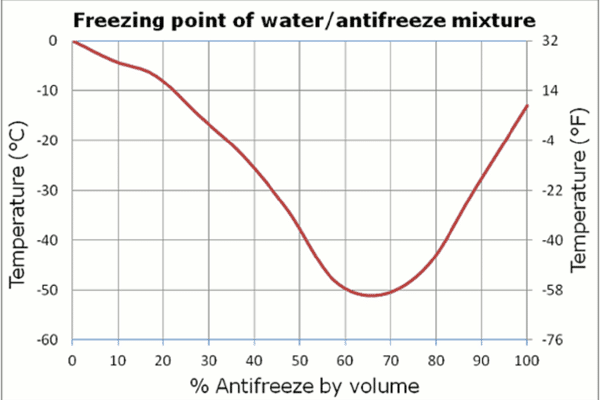

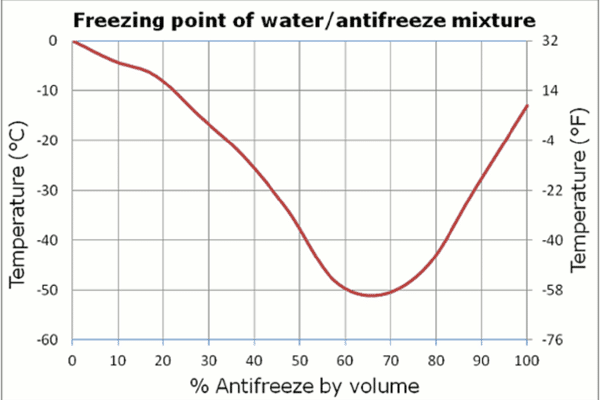

¿Qué función cumple realmente un refrigerante, cuáles son las diferencias entre tecnologías y qué propiedades tienen? ¿Y por qué ya no es posible elegir un refrigerante bas...

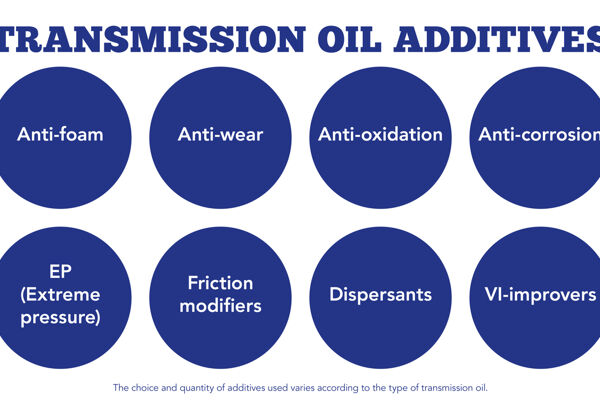

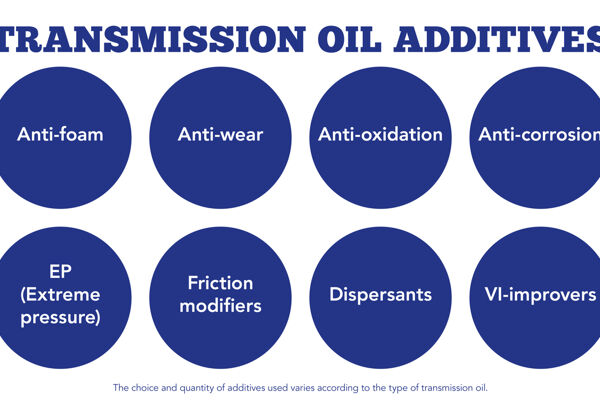

Ahorro de combustible, cambios de marcha más suaves, mayor vida útil y cárteres más pequeños: estos son los principales impulsores de la innovación en el ámbito de las tran...

Muchos vehículos diésel modernos utilizan AdBlue para cumplir con las normas de emisiones. Pero ¿qué es el AdBlue y cómo funciona? En este artículo lo explicamos con más de...

Debido a la crisis del coronavirus, muchos coches permanecen inmovilizados durante largos periodos de tiempo. Para evitar problemas y volver a la carretera con seguridad, q...

Con la llegada del verano, lo que más quieres es volver a disfrutar de la carretera con tu moto. ¿Quieres dejar tu motocicleta lista para rodar? ¡Entonces sigue estos 10 pa...

La primavera está a la vuelta de la esquina, así que es hora de sacar tu coche clásico de su almacenamiento invernal. Para un comienzo de temporada suave y seguro, Eurol qu...

Para reducir las emisiones de CO₂, se están aplicando en todo el mundo requisitos cada vez más estrictos para los turismos. Además de las innovaciones en la tecnología de m...

Cada vez más motores están equipados con turbos. Un turbo contiene tecnología avanzada y, por tanto, es muy vulnerable. Los problemas con el turbo pueden afectar al motor y...

Cada vez aparecen más dispositivos prácticos en el mercado que permiten evaluar la calidad del líquido de frenos. Sin embargo, debido a la frecuente pregunta sobre si estos...

Durante el invierno, puede resultar difícil arrancar el motor. Eurol ofrece dos aditivos que ayudan, incluso cuando el coche se siente lento o perezoso.

El medioambiente manda y los fabricantes tienen que aplicar todo tipo de estrategias para que los vehículos cumplan con las normas de emisiones. Esto suele provocar contami...

Hace una década, los mecánicos de taller solo podían elegir entre dos tipos de aceite. Hoy en día, sin embargo, ese número se ha multiplicado al menos por cinco. “Los fabri...

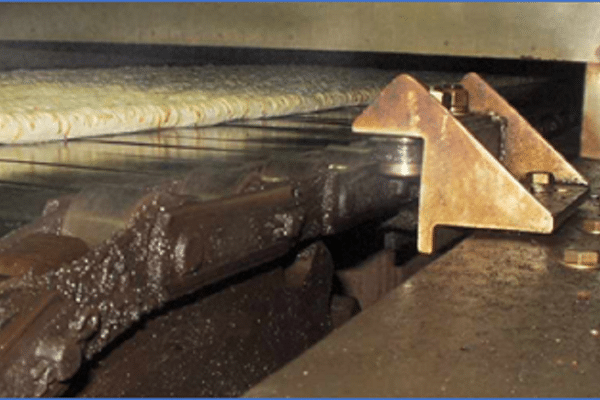

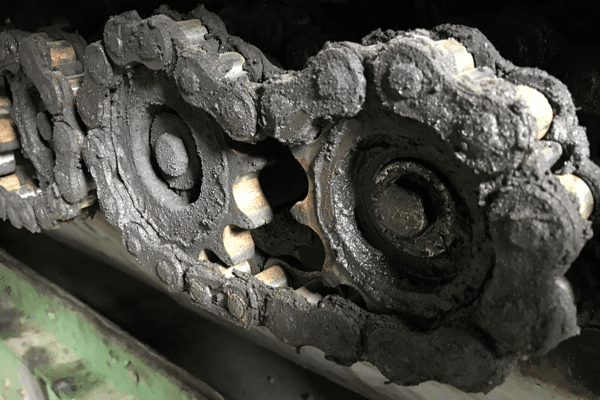

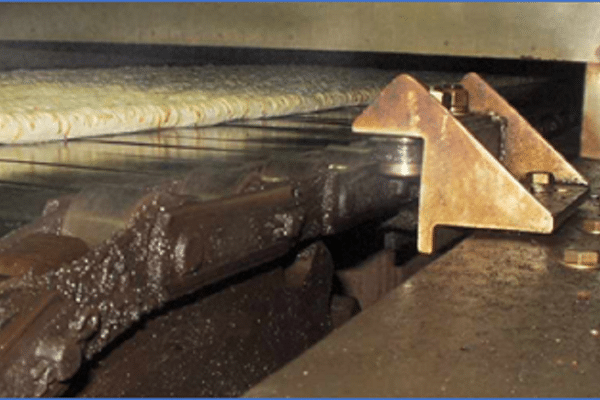

Chains and bearings in a tunnel oven need to be lubricated. However, this is often done with lubricants that are unsuitable for high-temperature applications.

El reciclaje de residuos somete los rodamientos a gran presión. Heros Sluiskil eligió una lubricación que mejora el rendimiento y la fiabilidad.

Las trituradoras de madera hacen un trabajo duro. Con nuestros lubricantes, duran más, con menos paradas, menor consumo y mejor lubricación de rodamientos.

En condiciones duras, una buena lubricación ayuda a que las segadoras rindan al máximo. En JvESCH, esto redujo el mantenimiento y los costes.

El tiempo de inactividad de los parquímetros cuesta dinero. Una lubricación adecuada garantiza su fiabilidad y reduce la frecuencia del mantenimiento.

Una buena lubricación de las máquinas y componentes, como los cables, es esencial. Esto es especialmente importante en equipos offshore, donde el sol, las salpicaduras de a...

Una buena lubricación de las máquinas es de gran importancia, especialmente para los equipos utilizados en el sector offshore, donde las condiciones ambientales y climática...

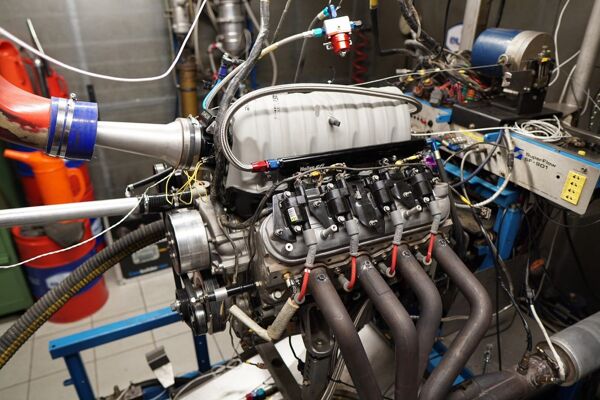

La caja de cambios secuencial está equipada con embragues de dientes como sincronizadores. Estos embragues están frecuentemente expuestos a un alto nivel de desgaste, ya qu...

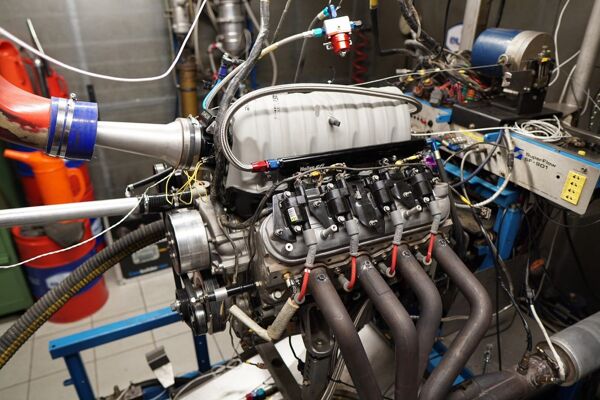

El motor está desarrollado para uso en competición. Todos los motores están sellados, por lo que los únicos beneficios de rendimiento pueden lograrse modificando los lubric...

Bob de Jong es un conocido piloto de rally neerlandés y también Campeón de Rally de los Países Bajos. Bob busca constantemente un mejor rendimiento y menos fricción para su...

Bob de Jong es un reconocido piloto de rally neerlandés y también Campeón Nacional de Rally. Bob busca constantemente un mejor rendimiento y menor fricción para su coche ut...

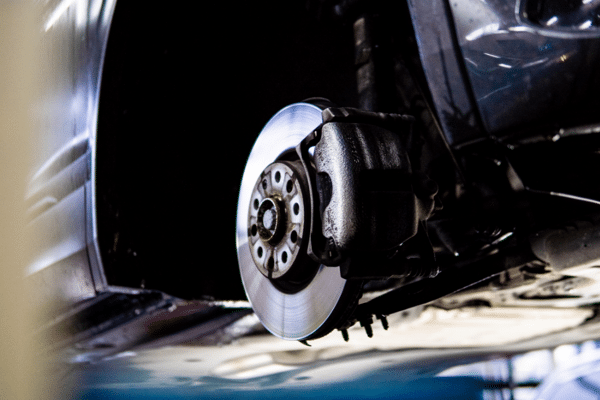

Porsche utiliza vectorización activa del par en las curvas aplicando los frenos en las ruedas interiores para aumentar la velocidad de paso por curva. En las competiciones ...

Los Porsche que compiten en circuito suelen utilizar aceite de motor estándar con especificación Porsche A40. Los propietarios experimentaban una presión de aceite más baja...

Motores ajustados para Mobil1 0W-30, un producto difícil de conseguir. El preparador neerlandés APP Racing Engines trabaja con un motor NASCAR con levas de empuje plano que...

Demasiado desgaste en los componentes y el uso de demasiados tipos de aceite diferentes. Además, la vida útil del aceite debía ser de al menos 6 etapas del Rally Dakar.

El líquido original de transmisión automática ZF no fue desarrollado para condiciones de competición. La protección a altas temperaturas no es óptima. Además, el desgaste e...

Durante el Rally Dakar, el motor funciona a plena carga durante horas, lo que provoca un aumento considerable de la temperatura. En estas condiciones, el aceite del motor s...

Sobrecalentamiento del diferencial en el BMW E46 M3 GTR. No se puede rellenar con 75W-140 debido al uso de un enfriador de aceite. Por lo tanto, se requiere un aceite para ...

Una quinta rueda normalmente dura tanto como la vida útil de un camión, pero en el caso de Bolk Transport, casi siempre se necesita una quinta rueda adicional.

Problemas de fluidez al utilizar una grasa fluida. También existía la posibilidad de una aplicación incorrecta entre las diferentes partes del camión, como la caja de trans...

Van den Boogaard está especializado en transporte, rescate de vehículos pesados y alquiler de grúas. El equipo, incluidas las grúas montadas en camiones, debe estar disponi...

Muchos camiones están equipados con muelles parabólicos. Los extremos de los muelles están lubricados para permitir la articulación. El calor radiante generado durante la r...

La caja de cambios funcionaba a más de 130 °C de temperatura en el cárter durante una carrera de resistencia de 12 horas con el aceite de transmisión utilizado en ese momen...

Los aceites de transmisión deben proteger todas las piezas lubricadas durante todo el Rally Dakar, con una fricción y un desgaste mínimos. Los productos utilizados anterior...

En Riwald Recycling, en Almelo, se trabaja intensamente con pinzas en grúas. Las grúas y pinzas giran durante todo el día y se ejerce una fuerza extrema sobre las piezas mó...

Polskamp Meat Industrie está especializada en la separación de carne de pollo del hueso. Las líneas de producción funcionan las 24 horas del día para procesar distintas par...

El motor funcionaba cada año con un aceite estándar 10W-60. Durante el Rally Dakar, el motor sufrió desgaste debido a la entrada de arena, además de caídas ocasionales en l...

Desde 2011, los turismos diésel deben contar con un filtro de partículas instalado por el fabricante para cumplir con las normativas europeas de emisiones. Por eso es aún m...

Los camiones están sujetos a normativas medioambientales cada vez más estrictas. No solo deben reducirse las emisiones de sustancias nocivas, sino también disminuir conside...

Un convertidor de par transfiere la potencia del motor a la transmisión. Cuando está desbloqueado, el convertidor patina constantemente, lo que genera fricción y calor. The...

En el procesamiento de tulipanes, la continuidad lo es todo. La lubricación adecuada de cadenas ayuda a Triflor en el forzado y la exportación.

Se solicitan productos Eurol específicos para diferentes marcas y tipos de vehículos. Esto plantea desafíos tanto logísticos como administrativos, lo que requiere una gesti...

Por qué el calor local es decisivo para la estrategia de refrigeración de los motores Volvo heavy duty y qué significa esto para la selección del refrigerante y el mantenim...

Los equipos Eurol vivieron un Rally Dakar 2026 lleno de acontecimientos con siete victorias de etapa, un podio para Mitchel van den Brink y sólidos debuts de Kay Huzink e I...

El joven talento mostró su mejor versión durante la primera semana del Dakar 2026, con sólidas actuaciones en camiones, coches y motos por parte de los participantes de Eur...

En el Dakar 2026, Eurol estará presente con una representación amplia. Con cuatro camiones, cuatro coches y una motocicleta, promete ser una edición emocionante.

La lubricación y la protección anticorrosiva mejoradas aumentaron la fiabilidad, redujeron los costes de mantenimiento y disminuyeron el tiempo de inactividad en aplicacion...

Descubra cómo los motores modernos de dos y cuatro tiempos evolucionan por las normas de emisiones y qué implica para el mantenimiento y la elección del aceite.

Eurol introduce el Actence 0W-16, desarrollado para los motores híbridos y de gasolina más recientes de Renault y Dacia.

Descubra cómo Eurol Grease CS 2 103S evita el desgaste grave y el tiempo de inactividad en un rodillo CNC Haeusler gracias a una lubricación resistente a la presión y un co...

La formación de espuma en los sistemas de frenos húmedos puede provocar pérdida de presión, desgaste y fallos. Lea cómo se produce, cuáles son sus consecuencias y cómo evit...

Rocco Coronel, piloto júnior de Red Bull, se corona campeón del G40 Junior Championship con 11 victorias y 19 podios.

Lubricación fiable de husillos con Eurol Grease CS-2/502-S. Evite el desgaste, las fugas y el secado con la protección duradera de SYNGIS Technology.

Las cajas de engranajes industriales requieren una lubricación fiable para evitar pérdidas de energía, desgaste y paradas. En este artículo descubrirá cómo las estrategias ...

Eurol e Invicta Racing inician una asociación técnica de F2 con SYNGIS Technology para mayor rendimiento, eficiencia y fiabilidad en la Fórmula 2.

El TBN indica la capacidad del aceite para neutralizar ácidos. Es esencial cuando se utiliza combustible con alto contenido de azufre y en condiciones de alta exigencia, pa...

Al cambiar a Eurol Grease CS-2/103-S, una empresa de reciclaje de escombros ahorra 9 horas de dīkstāve por semana, con un arranque automático fluido del tambor y sin necesi...

El líquido de frenos suele pasarse por alto, pero es esencial para que el sistema de frenado funcione con seguridad. En este artículo le explicamos qué debe tener en cuenta...

Eurol apoya a Ian Olthof, el único piloto neerlandés en moto en el Rally Dakar 2026. Ian confía en los productos Eurol desde hace años y representa a la marca en el rally.

Lubricación potente y sostenible para aplicaciones de uso intensivo. Descubra tres nuevos biolubricantes con SYNGIS Technology que ofrecen el máximo rendimiento en cualquie...

Additive-S BIO reduce la temperatura del aceite en la Toro Greensmaster, lo que permite un corte más eficiente y sostenible con menos mantenimiento.

Álex Palou gana la 109ª edición de las 500 Millas de Indianápolis para Chip Ganassi Racing. Eurol, como socio técnico, ha contribuido de manera esencial a este logro.

La baja calidad del diésel provoca inyectores contaminados y problemas en el motor en el sector del transporte. Descubre cómo una solución inteligente añadida al combustibl...

La sal y las cargas pesadas provocaban fallos en el sistema de carga de Bolk Transport. Con Eurol Lube CL-F Spray, todo vuelve a funcionar sin problemas.

Evita los daños por óxido en el remolque de tu embarcación con la protección adecuada y prolonga la vida útil de los componentes vitales.

Una furgoneta pequeña con problemas de arranque, pérdida de potencia y mayor consumo es diagnosticada y reparada con profesionalidad en nuestro taller.

Lama Chemie es el distribuidor de lubricantes sostenibles y especiales de Eurol con mayor crecimiento en 2024.

La lubricación especializada prolonga la vida útil y mejora la eficiencia de las dragas de tolva de succión por arrastre en condiciones extremas.

Noroil gana el premio Eurol Specialty Dealer of the Year 2024 gracias a su sólido crecimiento en lubricantes industriales y fluidos técnicos en Noruega.

Una empresa de grúas se enfrentaba a una fuerte corrosión en los cables del plumín de sus grúas torre móviles, lo que provocaba elevados costes de mantenimiento e inspeccio...

¿Lubricar una cadena con grasa o con aceite? En este artículo descubrirás las diferencias y recibirás asesoramiento experto sobre el mejor método de lubricación para un ren...

Descubre las Eurol Swift Clean HD Wipes para una limpieza sin esfuerzo y sin agua, y el Swift Clean 130, ahora también disponible en un bidón de 20 L para uso frecuente.

Una empresa de taxis, con una amplia flota de vehículos equipados con transmisiones automáticas, está recibiendo cada vez más quejas sobre el comportamiento del cambio en a...

Foodsafe y certificación NSF: lo que debes saber sobre productos de limpieza seguros

El Rally Dakar 2025 concluye con éxito para los equipos Eurol: Mitchel van den Brink y Henk Lategan brillan al conseguir ambos el segundo puesto en la clasificación final.

Debido a la reducción del tamaño de los motores de combustión interna, un nuevo fenómeno ocurre con más frecuencia: la preignición a baja velocidad (LSPI). La LSPI no se pu...

Tras cinco agotadoras etapas del Dakar, los participantes de Eurol disfrutan de un merecido día de descanso. Tanto Toyota GAZOO Racing South Africa como Eurol Rallysport ha...

Eurol se asociará con Chip Ganassi Racing como socio técnico para la temporada 2025 de la INDYCAR SERIES.

Eurol apoya a equipos de primer nivel preparados para la 47ª edición del Rally Dakar, que se celebrará del 3 al 17 de enero de 2025 en Arabia Saudí.

Eurol lanza el spray Lube PL-S, un lubricante seco versátil con SYNGIS Technology, ahora actualizado y ampliado con variantes sostenibles.

Eurol se enorgullece de anunciar que su colaboración con Rocco Coronel se intensifica. El apoyo se amplía a todas las actividades de competición de este joven talento neerl...

Extreme conditions in mining cause wear and downtime. Eurol offers solutions to improve the lifespan and efficiency of machinery.

Eurol presenta cuatro nuevos productos, desarrollados para diversos vehículos, incluidos turismos modernos, camiones y vehículos comerciales ligeros.

El nuevo Eurol Screenwash Safe Storage ofrece una solución sin restricciones de almacenamiento, es seguro de usar y garantiza una limpieza excelente.

Sustituir la grasa lubricante por Eurol Assembly Paste HT/FD permite un ahorro de al menos 50.000 € al año.

Estamos presentando ‘Carbon Neutral’, una línea de lubricantes totalmente CO₂-neutros.

Gaat u met de auto op vakantie? Voorkom pech onderweg met deze 5 slimme tips voor het controleren van vloeistoffen. Zo vertrekt u zorgeloos én goed voorbereid richting uw b...

Presentamos el Fultrax 75W-90 LS, un aceite de transmisión totalmente sintético con propiedades limited slip.

Utilizar un aditivo de enjuague al cambiar el aceite del motor es una forma sencilla de prevenir y eliminar la contaminación del motor. Requiere poco tiempo y ofrece múltip...

En la producción de adoquines decorativos prefabricados, un gran cepillo de acero automático que mantiene limpios los moldes desempeña un papel crucial para garantizar la c...

Organizaciones de diversos sectores están considerando aceites hidráulicos biodegradables por motivos de sostenibilidad y normativas, a pesar de dudas anteriores; las varia...

Presentamos el Transfluid ATF-CVT, una revolución en la tecnología de fluidos para transmisiones. Es el primer aceite de transmisión totalmente sintético adecuado tanto par...

Presentamos el Eurol Coolant -36 °C G12 EVO, un refrigerante de última generación desarrollado con tecnología LOBRID PSi-OAT, específicamente para los vehículos de nueva ge...

El distribuidor Valtec, de Rumanía, ha recibido por tercer año consecutivo el premio International Eurol Specialty Distributor.

En el sector del transporte vertical, la lubricación adecuada de las piezas deslizantes y los cables de acero es crucial. Las grasas obsoletas pueden provocar fallos y un m...

Hoy en día, existen soluciones especializadas modernas que permiten ahorrar energía y, al mismo tiempo, proteger de forma óptima las cajas de engranajes industriales contra...

Los códigos de color en los lubricantes son una parte fundamental para mantener un entorno de trabajo industrial seguro y eficiente. Lee más en este artículo informativo.

Reducir la huella de CO₂ de los procesos industriales es cada vez más importante. En este contexto, el ahorro energético desempeña un papel crucial.

Toyota GAZOO Racing buscaba soluciones para aumentar la durabilidad en sus coches de competición y mejorar el rendimiento.

Eurol anuncia la introducción del aceite de motor Ultrance ST 0W-20, una fórmula avanzada, totalmente sintética y ahorradora de combustible.

La limpieza de las piezas deslizantes con limpiador de frenos era un proceso laborioso y desfavorable desde el punto de vista de la salud laboral. El operario tenía que pro...

La lubricación de las piezas deslizantes suele realizarse con grasa estándar. Esta grasa, a diferencia del aceite, no se aplica fácilmente con un pincel.

Descubre cómo un lubricante innovador transforma la eficiencia y la sostenibilidad de los equipos de transporte y construcción vial, como grúas de carga, pinzas hidráulicas...

Los sistemas hidráulicos de estas máquinas hincadoras de pilotes estaban constantemente sometidos a una carga intensa, lo que resultaba en una vida útil reducida de la bomb...

Eurol Specialty CS-2/501 y CS-2/101 han contribuido a una reducción significativa del desgaste en los ejes de hélice.

Existen diversas razones para desactivar temporalmente las máquinas. Ya sea debido a los altos costos energéticos que obligan a algunas empresas a actuar con cautela, o al ...

Para los contratistas agrícolas, la fiabilidad de su maquinaria es fundamental para una operación exitosa y eficiente.

En los equipos de movimiento de tierras de servicio pesado, la lubricación de las conexiones pasador-casquillo desempeña un papel crucial en el mantenimiento del rendimient...

SMESH ha desarrollado un eje eléctrico modular con E-motor integrado, paquetes de embrague y sistemas de engranajes planetarios.

Eurol presenta E Heavy Duty Lube 46 BIO, un aceite hidráulico revolucionario desarrollado especialmente para excavadoras eléctricas.

Presentamos E Heavy Duty, una nueva generación de lubricantes desarrollados especialmente para la lubricación eficiente de maquinaria y vehículos eléctricos pesados.

En una planta de reciclaje de plástico y gestión de residuos, se enfrentaron a un desafío: fallos repetitivos en los rodamientos de trituradoras y secadoras.

Ciertos agentes de limpieza pueden dañar las cadenas transportadoras y los engranajes del túnel de lavado. Estos productos son tan agresivos que disuelven los lubricantes e...

En una obra que involucra hormigón armado y cables de acero pretensado, se utilizan “anclajes” o abrazaderas de acero para tensar y sujetar los cables.

Los rodamientos de los discos de corte del inyector de estiércol están sometidos a cargas pesadas y entran en contacto con estiércol, arena y agua. El amoníaco presente en ...

En una instalación agrícola dedicada al procesamiento de heno y paja, los operarios detectaron problemas en las cadenas de transporte. Las cadenas estaban húmedas y pegajos...

Recientemente, ha habido desarrollos significativos con respecto a las normas de emisiones Euro 7 para turismos, vehículos comerciales ligeros y vehículos industriales pesa...

En un campo de golf, normalmente se utilizan cinco tipos de cortacéspedes para mantener en buen estado los distintos tipos de césped y terrenos.

En las operaciones de manipulación y transferencia de contenedores en los puertos, se utiliza frecuentemente un Reachstacker. Esta máquina está equipada con componentes des...

El impacto de la nueva norma Euro 7 es significativo. Los fabricantes de camiones y autobuses deben cumplir con estrictas reglas dentro de esta norma medioambiental para re...

El impacto de la nueva norma Euro 7 es significativo. En este artículo técnico podrás leer todo lo que necesitas saber sobre la nueva norma Euro 7 y el papel de los lubrica...

Bajo la presión de las normativas de emisiones cada vez más estrictas en la industria automotriz, los motores turbo ligeros, de alto régimen y baja cilindrada se han conver...

Un caso práctico de un productor en la industria alimentaria que ha llegado a ahorrar hasta 20.000 € al año gracias a una reducción en el mantenimiento y el tiempo de inact...

Van den Boogaard is specialized in transport, heavy salvage, and crane rental. The equipment, including truck mounted cranes, must be available day and night under all circ...

In this case study we will discuss the effect of our specialty lubricants on these de-icing machines. We show how our Eurol Specialty products contribute to less maintenanc...

En la práctica, la lubricación adecuada del equipo agrícola a menudo se descuida. Puntos de engrase esenciales no se lubrican o no se lubrican correctamente. El resultado e...

Seguramente te resulta familiar la siguiente situación: llegas a un semáforo y el motor se apaga. Afortunadamente, se vuelve a encender cuando quieres continuar. ¿Irritante...

¿Qué función cumple realmente un refrigerante, cuáles son las diferencias entre tecnologías y qué propiedades tienen? ¿Y por qué ya no es posible elegir un refrigerante bas...

Ahorro de combustible, cambios de marcha más suaves, mayor vida útil y cárteres más pequeños: estos son los principales impulsores de la innovación en el ámbito de las tran...

Muchos vehículos diésel modernos utilizan AdBlue para cumplir con las normas de emisiones. Pero ¿qué es el AdBlue y cómo funciona? En este artículo lo explicamos con más de...

Debido a la crisis del coronavirus, muchos coches permanecen inmovilizados durante largos periodos de tiempo. Para evitar problemas y volver a la carretera con seguridad, q...

Con la llegada del verano, lo que más quieres es volver a disfrutar de la carretera con tu moto. ¿Quieres dejar tu motocicleta lista para rodar? ¡Entonces sigue estos 10 pa...

La primavera está a la vuelta de la esquina, así que es hora de sacar tu coche clásico de su almacenamiento invernal. Para un comienzo de temporada suave y seguro, Eurol qu...

Para reducir las emisiones de CO₂, se están aplicando en todo el mundo requisitos cada vez más estrictos para los turismos. Además de las innovaciones en la tecnología de m...

Cada vez más motores están equipados con turbos. Un turbo contiene tecnología avanzada y, por tanto, es muy vulnerable. Los problemas con el turbo pueden afectar al motor y...

Cada vez aparecen más dispositivos prácticos en el mercado que permiten evaluar la calidad del líquido de frenos. Sin embargo, debido a la frecuente pregunta sobre si estos...

Durante el invierno, puede resultar difícil arrancar el motor. Eurol ofrece dos aditivos que ayudan, incluso cuando el coche se siente lento o perezoso.

El medioambiente manda y los fabricantes tienen que aplicar todo tipo de estrategias para que los vehículos cumplan con las normas de emisiones. Esto suele provocar contami...

Hace una década, los mecánicos de taller solo podían elegir entre dos tipos de aceite. Hoy en día, sin embargo, ese número se ha multiplicado al menos por cinco. “Los fabri...

Chains and bearings in a tunnel oven need to be lubricated. However, this is often done with lubricants that are unsuitable for high-temperature applications.

El reciclaje de residuos somete los rodamientos a gran presión. Heros Sluiskil eligió una lubricación que mejora el rendimiento y la fiabilidad.

Las trituradoras de madera hacen un trabajo duro. Con nuestros lubricantes, duran más, con menos paradas, menor consumo y mejor lubricación de rodamientos.

En condiciones duras, una buena lubricación ayuda a que las segadoras rindan al máximo. En JvESCH, esto redujo el mantenimiento y los costes.

El tiempo de inactividad de los parquímetros cuesta dinero. Una lubricación adecuada garantiza su fiabilidad y reduce la frecuencia del mantenimiento.

Una buena lubricación de las máquinas y componentes, como los cables, es esencial. Esto es especialmente importante en equipos offshore, donde el sol, las salpicaduras de a...

Una buena lubricación de las máquinas es de gran importancia, especialmente para los equipos utilizados en el sector offshore, donde las condiciones ambientales y climática...

La caja de cambios secuencial está equipada con embragues de dientes como sincronizadores. Estos embragues están frecuentemente expuestos a un alto nivel de desgaste, ya qu...

El motor está desarrollado para uso en competición. Todos los motores están sellados, por lo que los únicos beneficios de rendimiento pueden lograrse modificando los lubric...

Bob de Jong es un conocido piloto de rally neerlandés y también Campeón de Rally de los Países Bajos. Bob busca constantemente un mejor rendimiento y menos fricción para su...

Bob de Jong es un reconocido piloto de rally neerlandés y también Campeón Nacional de Rally. Bob busca constantemente un mejor rendimiento y menor fricción para su coche ut...

Porsche utiliza vectorización activa del par en las curvas aplicando los frenos en las ruedas interiores para aumentar la velocidad de paso por curva. En las competiciones ...

Los Porsche que compiten en circuito suelen utilizar aceite de motor estándar con especificación Porsche A40. Los propietarios experimentaban una presión de aceite más baja...

Motores ajustados para Mobil1 0W-30, un producto difícil de conseguir. El preparador neerlandés APP Racing Engines trabaja con un motor NASCAR con levas de empuje plano que...

Demasiado desgaste en los componentes y el uso de demasiados tipos de aceite diferentes. Además, la vida útil del aceite debía ser de al menos 6 etapas del Rally Dakar.

El líquido original de transmisión automática ZF no fue desarrollado para condiciones de competición. La protección a altas temperaturas no es óptima. Además, el desgaste e...

Durante el Rally Dakar, el motor funciona a plena carga durante horas, lo que provoca un aumento considerable de la temperatura. En estas condiciones, el aceite del motor s...

Sobrecalentamiento del diferencial en el BMW E46 M3 GTR. No se puede rellenar con 75W-140 debido al uso de un enfriador de aceite. Por lo tanto, se requiere un aceite para ...

Una quinta rueda normalmente dura tanto como la vida útil de un camión, pero en el caso de Bolk Transport, casi siempre se necesita una quinta rueda adicional.

Problemas de fluidez al utilizar una grasa fluida. También existía la posibilidad de una aplicación incorrecta entre las diferentes partes del camión, como la caja de trans...

Van den Boogaard está especializado en transporte, rescate de vehículos pesados y alquiler de grúas. El equipo, incluidas las grúas montadas en camiones, debe estar disponi...

Muchos camiones están equipados con muelles parabólicos. Los extremos de los muelles están lubricados para permitir la articulación. El calor radiante generado durante la r...

La caja de cambios funcionaba a más de 130 °C de temperatura en el cárter durante una carrera de resistencia de 12 horas con el aceite de transmisión utilizado en ese momen...

Los aceites de transmisión deben proteger todas las piezas lubricadas durante todo el Rally Dakar, con una fricción y un desgaste mínimos. Los productos utilizados anterior...

En Riwald Recycling, en Almelo, se trabaja intensamente con pinzas en grúas. Las grúas y pinzas giran durante todo el día y se ejerce una fuerza extrema sobre las piezas mó...

Polskamp Meat Industrie está especializada en la separación de carne de pollo del hueso. Las líneas de producción funcionan las 24 horas del día para procesar distintas par...

El motor funcionaba cada año con un aceite estándar 10W-60. Durante el Rally Dakar, el motor sufrió desgaste debido a la entrada de arena, además de caídas ocasionales en l...

Desde 2011, los turismos diésel deben contar con un filtro de partículas instalado por el fabricante para cumplir con las normativas europeas de emisiones. Por eso es aún m...

Los camiones están sujetos a normativas medioambientales cada vez más estrictas. No solo deben reducirse las emisiones de sustancias nocivas, sino también disminuir conside...

Un convertidor de par transfiere la potencia del motor a la transmisión. Cuando está desbloqueado, el convertidor patina constantemente, lo que genera fricción y calor. The...

En el procesamiento de tulipanes, la continuidad lo es todo. La lubricación adecuada de cadenas ayuda a Triflor en el forzado y la exportación.

Se solicitan productos Eurol específicos para diferentes marcas y tipos de vehículos. Esto plantea desafíos tanto logísticos como administrativos, lo que requiere una gesti...