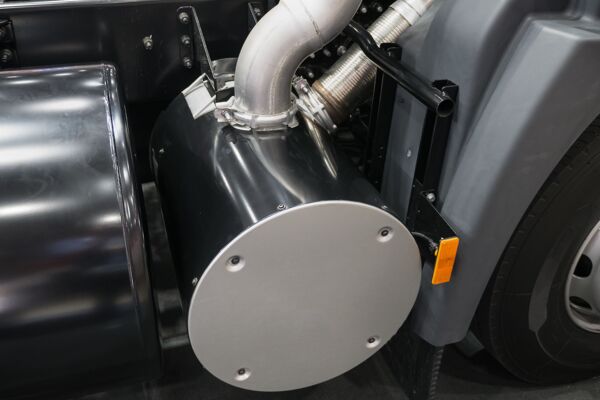

The cooling strategy of Volvo heavy duty engines

Why local heat is decisive for the cooling strategy of Volvo heavy duty engines and what this means for coolant selection and maintenance.

November 23, 2021

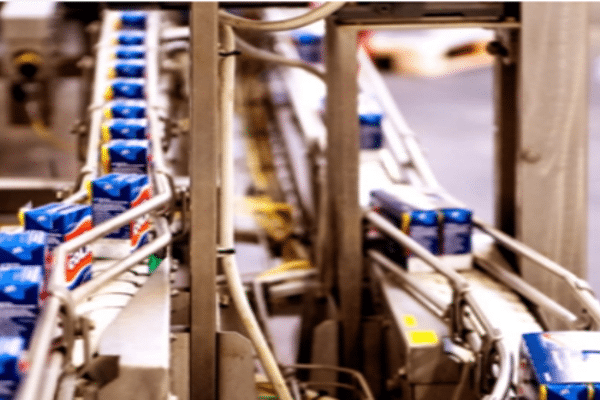

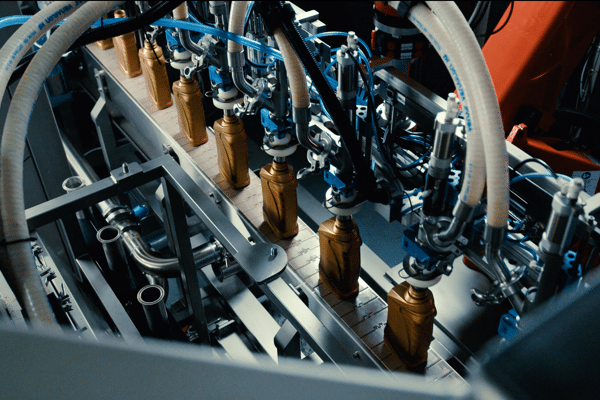

Increased Production Capacity: 50%

Value Savings: between €10,000 and €20,000

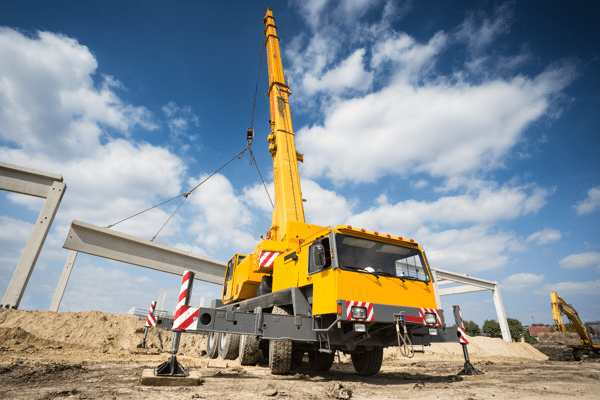

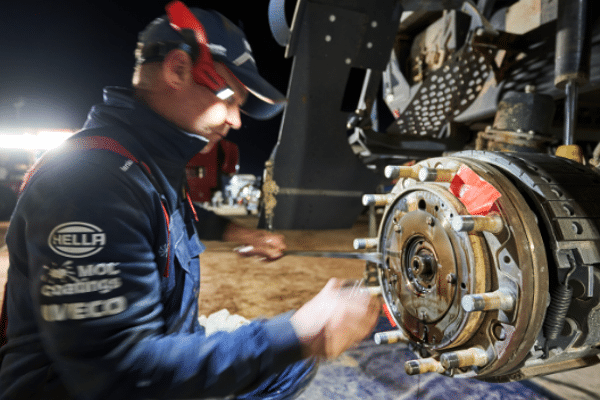

Good lubrication of machines and machine parts such as cables is essential. This is especially true for equipment in the offshore where sun, splashing salt water from the sea, wind and rain have free play. In this case study we will discuss the effect of our Specialty Lubricants in the offshore sector. We show how our Eurol Specialty products contribute to less maintenance work and less downtime.

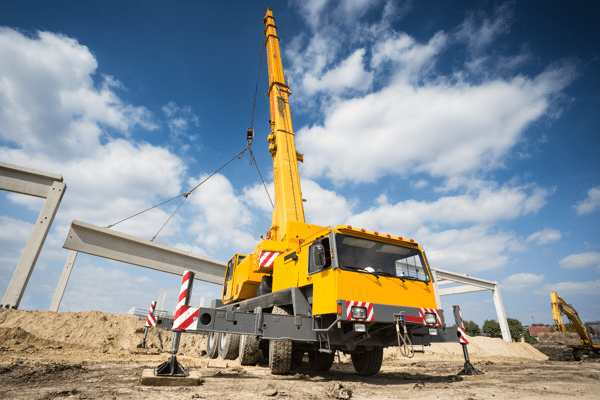

Due to the use of regular lubricants and greases there was a corrosion and lubrication problem of steel cables, open lubrication points and telescopic crane parts. This caused high maintenance costs and early replacement of cables and other parts.

| Market | Offshore |

| Lubrication Point | Steel cables | Telescopic crane components |

| Product | |

| Article Number | S005121AER S009101AER |

| Product Usage | Regular lubricants |

With Eurol Grease CS2 / 502-S Spray the telescopic parts of the crane were lubricated. The cable and other blank metal parts were protected with Eurol Lube PL Spray. This all resulted in a 2x longer service life of the steel cable and virtually no wear or corrosion of the crane parts. Less maintenance is required and so downtime is reduced.

Product usage: about 1 box (12p) spray cans each per year.

Why local heat is decisive for the cooling strategy of Volvo heavy duty engines and what this means for coolant selection and maintenance.

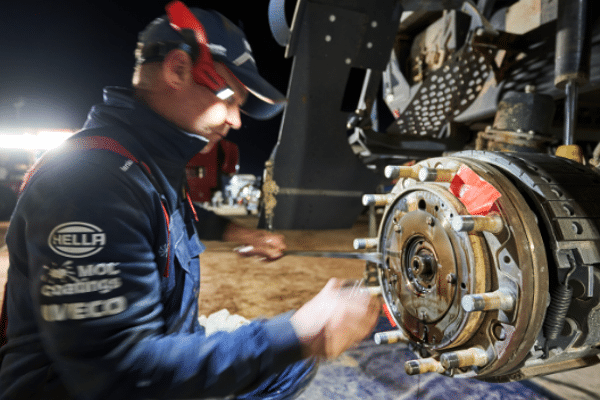

The Eurol-teams experienced an eventful Dakar Rally 2026 with seven stage victories, a podium for Mitchel van den Brink and strong debuts by Kay Huzink and Ian Olthof.

Young talent is showing its best side during the first week of Dakar 2026, delivering strong performances in the truck, car and motorcycle categories.

In Dakar 2026, Eurol will appear at the start with a wide representation. With four trucks, four cars and one motorcycle, it promises to be an exciting edition. ...

Improved lubrication and corrosion protection increased reliability, lowered maintenance costs and reduced downtime in demanding tunnel drill applications.

Discover how modern two- and four-stroke engines evolve due to emission standards and what this means for maintenance, oil choice and machine performance.

Eurol introduces the Actence 0W-16, developed for the latest hybrid and petrol engines from Renault & Dacia.

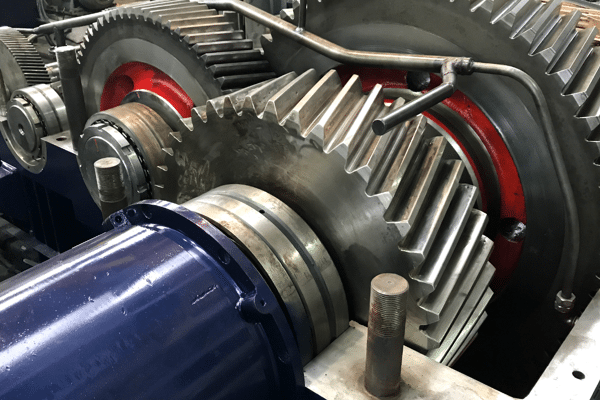

Discover how Eurol Grease CS 2 103S prevents severe wear and downtime in a Haeusler CNC roller through pressure resistant lubrication and stable flow behaviour.

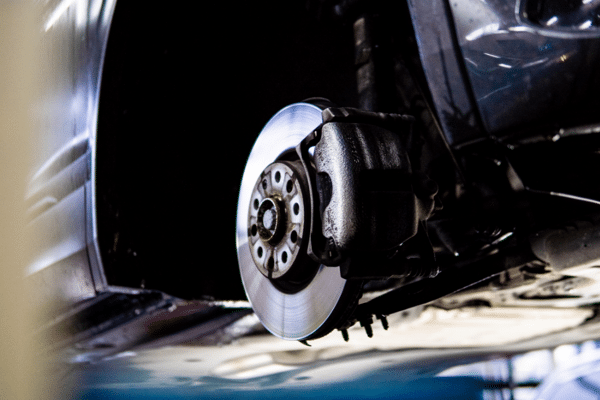

Foam formation in wet brake systems can lead to pressure loss, wear, and malfunctions. Read how this occurs, what the consequences are, and how to prevent it.

Rocco Coronel, Red Bull Junior, has claimed the G40 Junior Championship title with 11 victories and 19 podium finishes.

Reliable spindle lubrication with Eurol Grease CS-2/502-S. Prevent wear, leakage, and drying with long-lasting SYNGIS Technology protection.

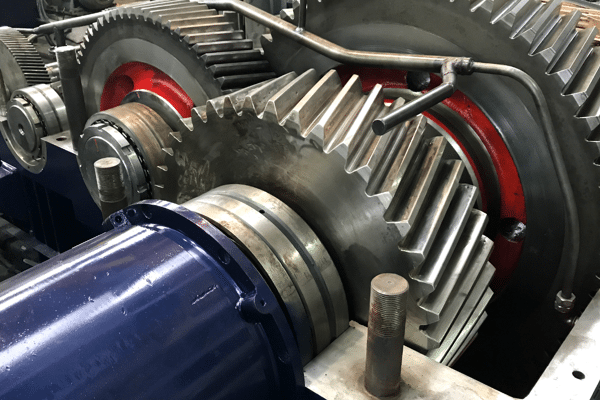

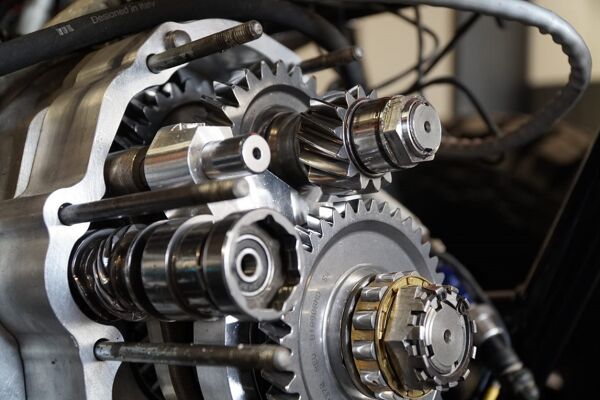

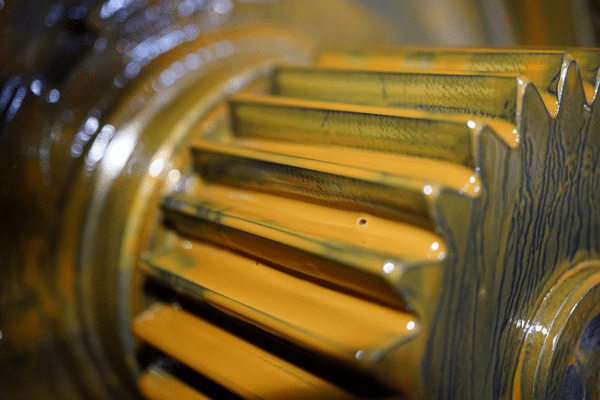

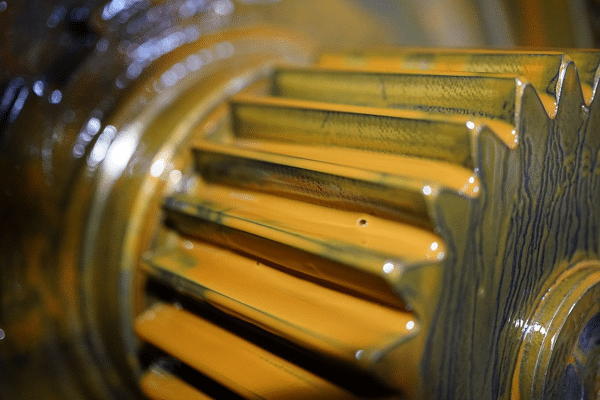

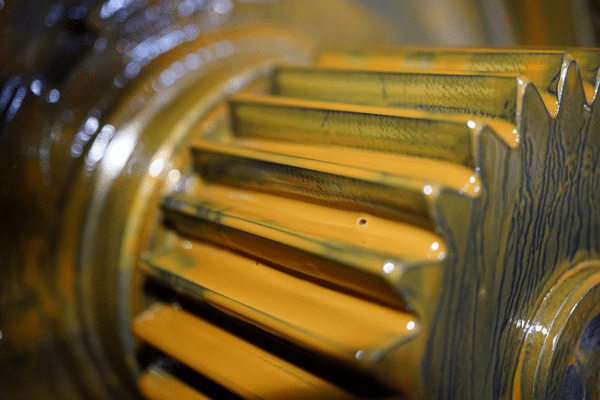

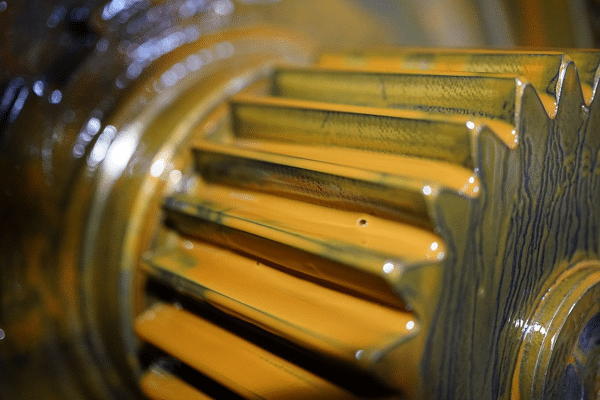

Industrial gearboxes require reliable lubrication to prevent energy loss, wear, and downtime. In this article, you will learn how modern lubrication strategies – from advan...

Eurol and Invicta Racing launch a technical F2 partnership with SYNGIS Technology for greater performance, efficiency, and reliability in Formul...

TBN indicates the acid-neutralising capacity of an oil. Essential when using sulphur-rich fuel and under heavy-duty conditions, to protect against corrosion and wear.

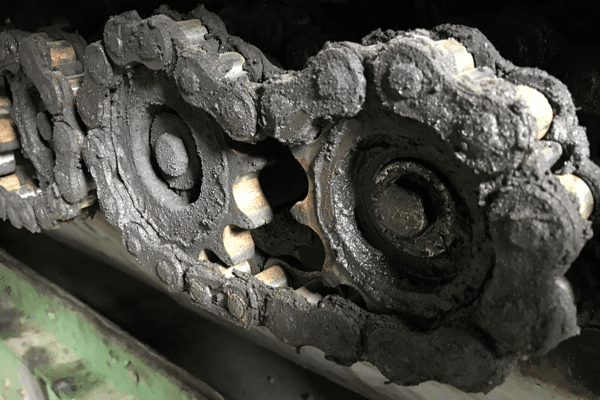

By switching to Eurol Grease CS-2/103-S, a rubble recycler saves 9 hours of downtime per week, with smooth automatic drum start-up and no more manual rocking required.

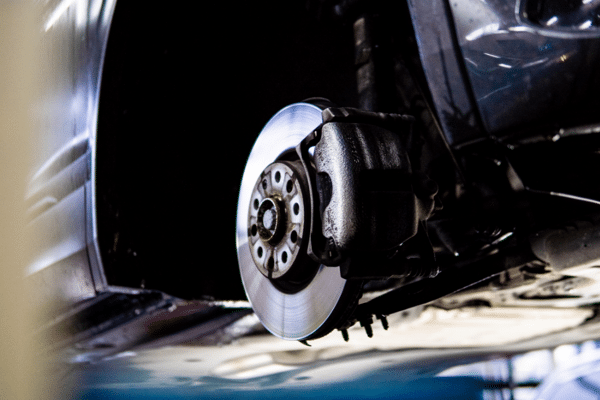

Brake fluid is often overlooked but crucial for a safely operating braking system. This article explains what to consider when choosing and replacing it.

Eurol supports Ian Olthof, the only Dutch motorcycle rider in the Dakar Rally 2026. Ian has been relying on Eurol products for years and represents the brand in the rally.

Driving on holiday? Avoid breakdowns with these 5 smart fluid-check tips. Set off worry-free and well-prepared for your journey.

Powerful and sustainable lubrication for heavy-duty applications. Discover three new bio-lubricants with SYNGIS Technology that deliver top performance under all conditions...

Additive-S BIO lowers the oil temperature of the Toro Greensmaster, enabling more efficient and sustainable mowing with reduced maintenance.

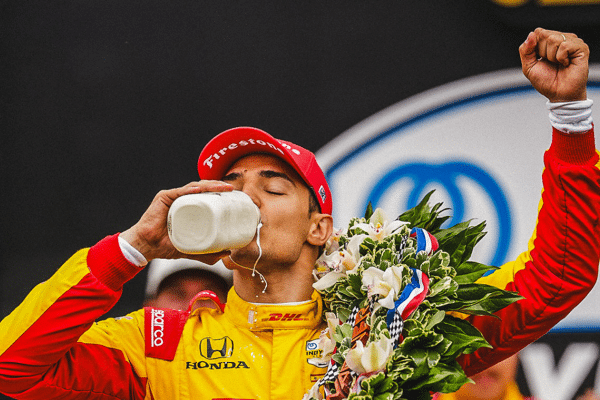

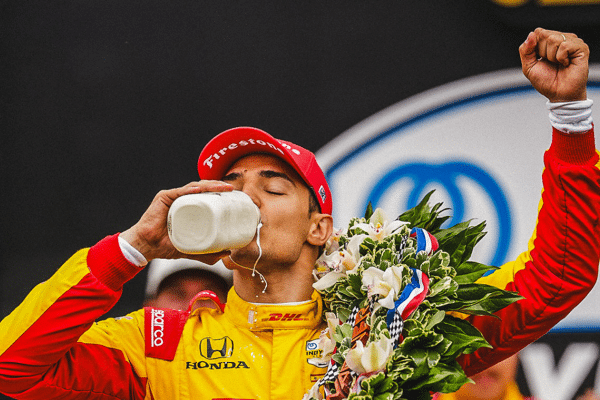

Alex Palou wins the 109th Indianapolis 500 for Chip Ganassi Racing. Eurol, as a technical partner, made an essential contribution to this achievement.

Poor diesel quality causes clogged injectors and engine problems in the transport sector. Discover how a smart fuel additive not only cuts breakdowns in half but also saves...

Salt and heavy loads caused failures in the loading system at Bolk Transport. With Eurol Lube CL-F Spray, everything runs smoothly again.

Prevent rust damage to your boat trailer with the right protection and extend the lifespan of vital components.

A small van with starting issues, loss of power, and increased consumption is expertly and repaired by our.

Lama Chemie is the fastest growing dealer in sustainable and specialty lubricants from Eurol in 2024.

Specialized lubrication extends the lifespan and enhances the efficiency of trailing suction hopper dredgers under harsh conditions.

Noroil wins the Eurol Specialty Dealer of the Year Award 2024 thanks to strong growth in industrial lubricants and technical fluids in Norway.

A crane company was faced with severe corrosion on the jib cables of their mobile tower cranes, leading to high maintenance costs and complex inspections

A frequently asked question is whether a chain should be lubricated with grease or oil. In this article, we explain the differences between oil and grease and provide advic...

Discover the Eurol Swift Clean HD Wipes for effortless cleaning water and the Swift Clean 130 - now also available in a 20L can for high-volume users.

A taxi company, with an extensive fleet of vehicles equipped with automatic transmissions, is experiencing increasing complaints about the shifting behavior of some of thei...

NSF approval guarantees safety when used correctly, but does not mean that a product is 'Foodsafe' for direct food contact. Understanding the different NSF categories helps...

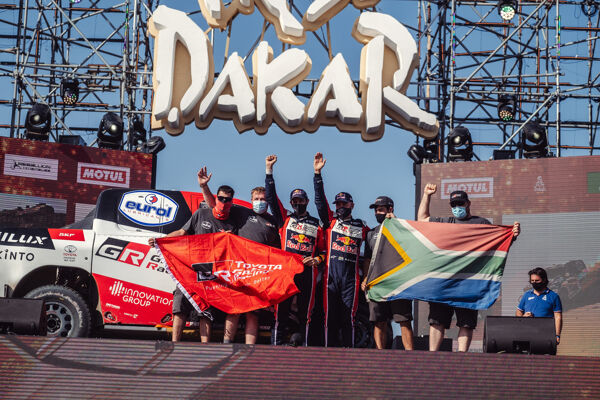

The Dakar Rally 2025 concludes successfully for the Eurol teams: Mitchel van den Brink and Henk Lategan shine with both securing 2nd place in the final standings!

Because of internal combustion engine downsizing, a new phenomenon occurs more often: Low Speed Pre Ignition (LSPI). LSPI cannot be heard and cannot be foreseen, however it...

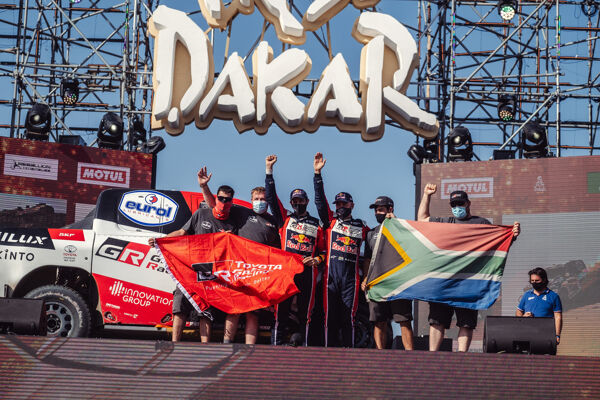

Discover which Eurol lubricants contribute to the success of Toyota GAZOO Racing in the Dakar Rally. We apply our expertise from the toughest rally in the world to innovati...

After five tough Dakar stages, the Eurol participants enjoy a well-deserved rest day. Both teams experienced successes and setbacks.

Eurol will partner with Chip Ganassi Racing as a technical partner for the 2025 INDYCAR SERIES season.

Eurol supports top teams ready for the 47th edition of the Dakar Rally, taking place from January 3 to 17, 2025, in Saudi Arabia.

Eurol launches the Lube PL-S spray, a versatile dry lubricant with SYNGIS Technology, now updated and expanded with sustainable variants.

Eurol strengthens its partnership with young racing talent Rocco Coronel, who, alongside his karting activities, is now also supported in the Ginetta Junior Championship.

Extreme conditions in mining cause wear and downtime. Eurol offers solutions to improve the lifespan and efficiency of machinery.

Eurol introduces four new products, developed for various vehicles, including modern passenger cars, trucks, and light commercial vehicles.

The new Eurol Screenwash Safe Storage offers a solution without storage restrictions, is safe to use, and guarantees excellent cleaning.

Using Eurol Assembly Paste HT/FD for drilling equipment in the steel industry prevents carbonization, extends machine lifespan, and reduces downtime, saving over €50,000 an...

We are introducing ‘Carbon Neutral,’ a line of lubricants that are fully CO2-neutral.

Visit Eurol during Automechanika in Frankfurt from September 10 to 14, 2024. Hall 12, stand E11.

The Dutch lubricant manufacturer Eurol has acquired Eurol Lubricants Österreich.

We introduce the Fultrax 75W-90 LS, a fully synthetic transmission oil with limited slip properties.

Using an engine oil flush additive when changing the engine oil is a simple way to prevent and remedy engine contamination. It takes little time and has multiple benefits.

Mitchel van den Brink and navigator Bart van Heun from the Eurol Rally Sport team have won the 2024 Morocco Desert Challenge in the overall SSV classification.

In the production of prefabricated decorative paving, a large automatic steel brush for keeping the molds clean plays a crucial role in ensuring quality.

Tom Coronel will continue his racing activities this season with technical support from Eurol, participating in the Nuerburgring Langstreckenmeisterschaft in a Porsche 911 ...

Keep your racing bike in optimal condition. By using the professional Eurol Specialty products, you make a difference on the bike and in the workshop.

Eurol is proud to announce that we are the new lubricant partner of rally talent Yannick Vrielink. The 25-year-old racer, who clinched the champion title of the Dutch Toyot...

Organizations in various sectors are considering biodegradable hydraulic oils due to sustainability and regulations, despite past doubts.

We introduce the Transfluid ATF-CVT, a revolution in transmission fluid technology. This is the first fully synthetic transmission oil suitable for both conventional automa...

We introduce the Eurol Coolant -36°C G12 EVO. This is a state-of-the-art coolant developed from LOBRID PSi-OAT technology, specifically for the latest generation vehicles o...

Distributor Valtec from Romania has received the International Eurol Specialty Distributor award for the third consecutive year.

In the vertical transport sector, proper lubrication of sliding parts and steel cables is crucial. Outdated greases can lead to malfunctions and increased maintenance. Mode...

Nowadays, modern specialized solutions are available to save energy while simultaneously optimally protecting industrial gearboxes against wear and leakage..

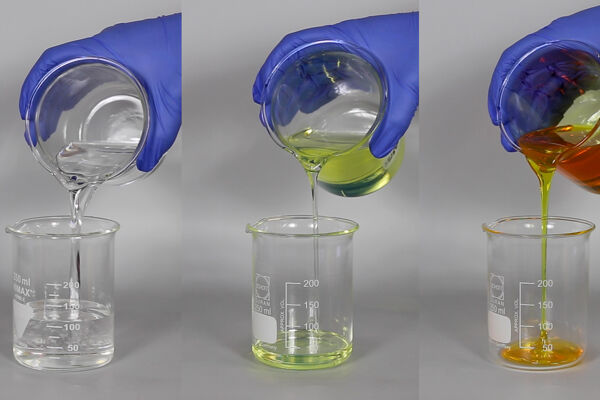

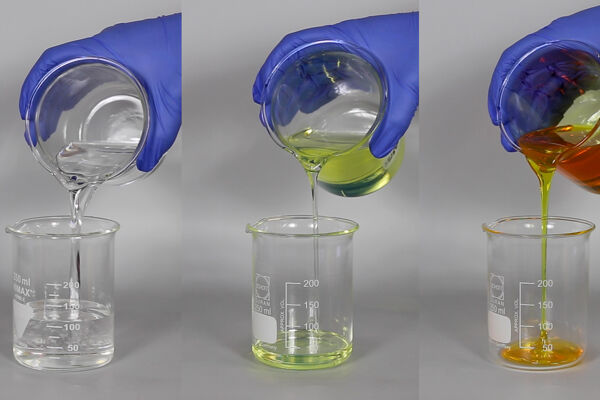

Lubricant color codes are an integral part of maintaining a safe and efficient industrial working environment. Read more in this knowledge article.

The final stage of the 2024 Dakar Rally has concluded! Today, the drivers tackled a challenging 175 km stretch through rocky terrain, culminating in a stunning finish along...

After six tough stages, the participants are enjoying a well-deserved rest day. The first week of the Dakar has proven to be a real endurance test for various teams.

There are various reasons for temporarily decommissioning machines. One crucial step is essential to ensure a trouble-free restart.

Reducing the CO2 footprint of industrial processes is becoming increasingly important. In this, energy saving plays a crucial role.

With the 2024 Dakar Rally approaching, Saudi Arabia will once again be the backdrop for the world's toughest rally from January 5 to 19.

Toyota GAZOO Racing was seeking solutions to increase durability in their race cars and improve performance.

Eurol announces the introduction of the Ultrance ST 0W-20 engine oil, an advanced fuel-saving and fully synthetic formula.

Cleaning the sliding parts with brake cleaner was a labor-intensive process and unfavorable from an occupational health perspective. The worker had to protect themselves ag...

The lubrication of sliding parts is often done with standard grease. Unlike oil, this grease is not easily applied with a brush.

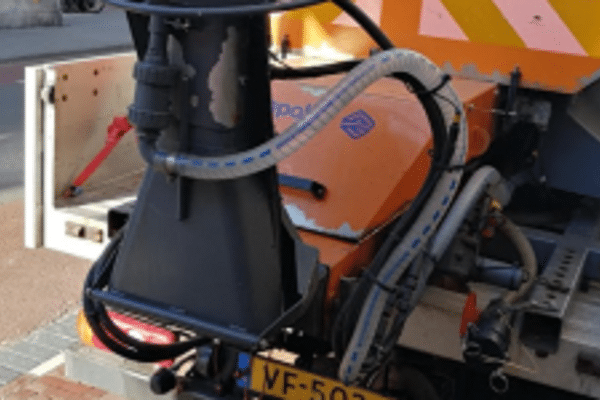

Discover how an innovative lubricant transforms the efficiency and sustainability of transport and road construction equipment, such as loading cranes, grabs, dump trucks, ...

The hydraulic systems of these pile driving machines were constantly under heavy load, which resulted in a shortened lifespan of the pump.

The door locking mechanism of sea containers operates through a lever principle. The hinges and the lock or closing mechanism are traditionally lubricated with lithium grea...

Eurol Specialty CS-2/501 and CS-2/101 have contributed to a significant reduction in wear on the propeller shafts.

In heavy-duty earthmoving equipment, the lubrication of pin-in-bush connections plays a crucial role in maintaining the performance and lifespan of the machines.

For agricultural contractors, the reliability of their equipment is central to a successful and efficient operation.

Eurol introduces E Heavy Duty Lube 46 BIO, a groundbreaking hydraulic oil specially developed for electric excavators.

SMESH have developed a modular e-axle with integrated E-motor, clutch packs and planetary gear systems.

We introduce E Heavy Duty, a new generation of lubricants specially developed for the efficient lubrication of electrified heavy machinery and vehicles.

We hereby announce the launch of our new website, E-Commerce environment, Product Information Management system, and Brand Po...

We warmly welcome you to the AgriTechnica fair in Hanover, the world’s largest trade fair for agricultural machinery.

In a factory for plastic recycling and waste management, they encountered a challenge, namely repeated defects in bearings in shredders and dryers.

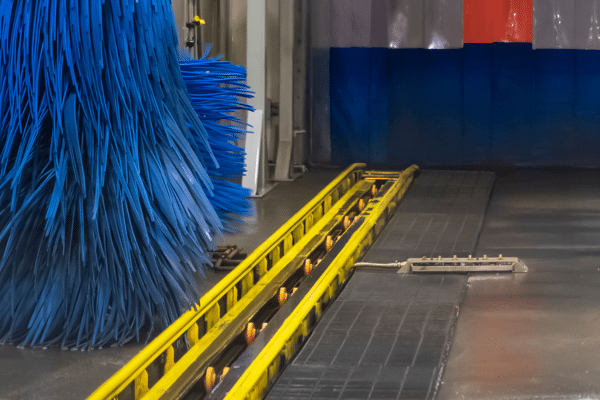

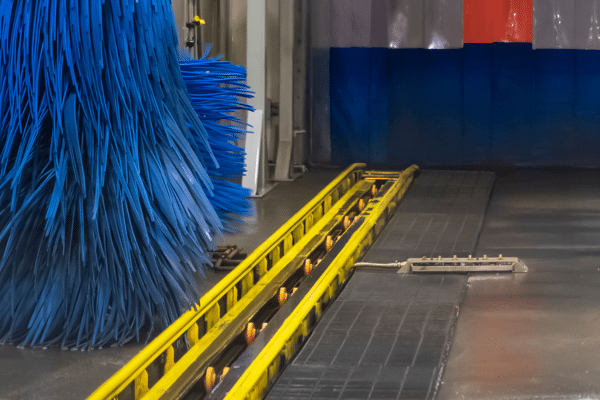

Certain cleaning agents can damage the conveyor chains and gears of the car wash. The cleaning agents are so strong that they dissolve standard lubricants, leaving the chai...

Tom Coronel has become champion in the TCR Europe Series for the first time in his illustrious racing career in 2023.

Toyota GAZOO Racing has become world champion in the Rally-Raid discipline for the second consecutive year.

In a construction involving reinforced concrete and prestressed steel cables, "Anchors," or steel clamps, are used to tension and hold the cables.

The disc coulter bearings of the manure injector undergo heavy loads and come into contact with manure, sand, and water. The ammonia present in the manure leads to an alkal...

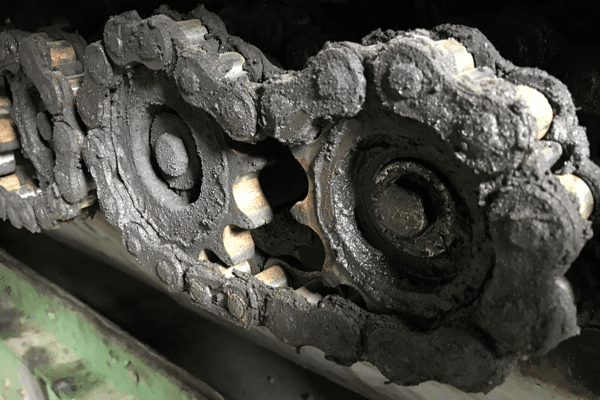

At an agricultural facility that processes hay and straw, operators discovered problems with the conveyor chains. The chains were wet and sticky, attracting dust, sand and ...

Recently, there have been significant developments regarding the Euro 7 emission standards for passenger cars, light commercial vehicles, and heavy commercial vehicles.

On a golf course, typically five types of lawnmowers are used to maintain all the different types of grass and terrains in good condition.

We will showcase our Eurol Specialty Racing lubricants with SYNGIS Technology at the international racing fair in Köln Messe, Cologne, Germany on November 8 and 9.

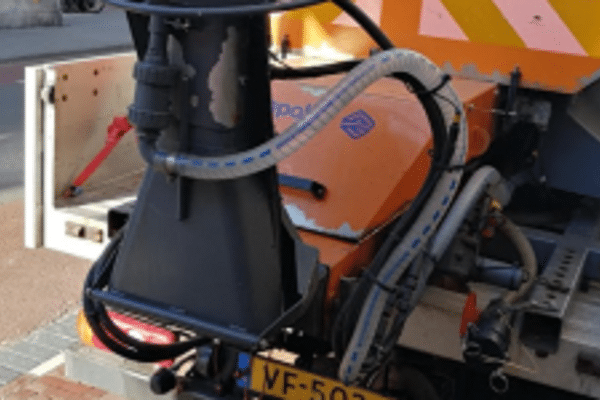

Proper lubrication of machinery is essential. This is certainly true for gritters that need to keep our roads safe to drive on during the winter months. In this case study,...

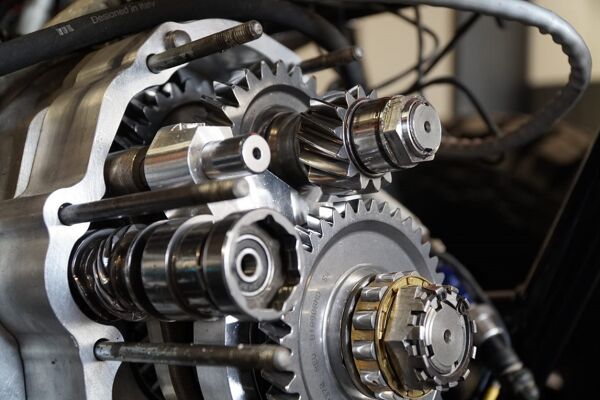

The sequential gearbox is equipped with dog clutches as synchronizers. These dog clutches are often subject to high wear, as they need to engage while the vehicle is operat...

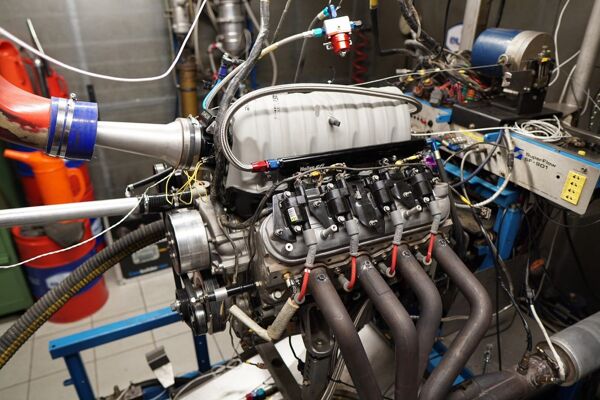

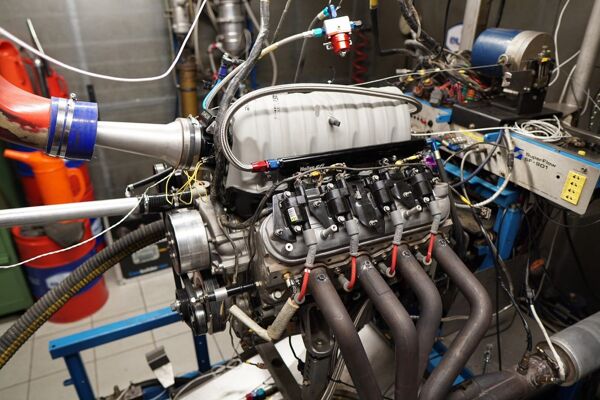

Engine is developed for competition use. All engines are sealed, only performance benefits can be achieved by altering lubricants such as the engine oil. Eurol Racing 0W-40...

Bob de Jong is a famous Dutch rally driver and also the Dutch Rally Champion. Bob is always looking for better performances and less friction for the car by using the best ...

Flowability issues when using a fluid grease. Also possibility of misapplication between different parts of the truck, such as transfer case, differentials and hub reductio...

Van den Boogaard is specialized in transport, heavy salvage, and crane rental. The equipment, including truck mounted cranes, must be available day and night under all circ...

The transmission oils have to protect all lubricated parts during the complete Dakar Rally with minimal friction and wear. The previously used products were acceptable but ...

At Riwald Recycling in Almelo, a lot of work is done with grabs on cranes. The cranes and grabs rotate all day long and an extreme amount of force is put on the moving part...

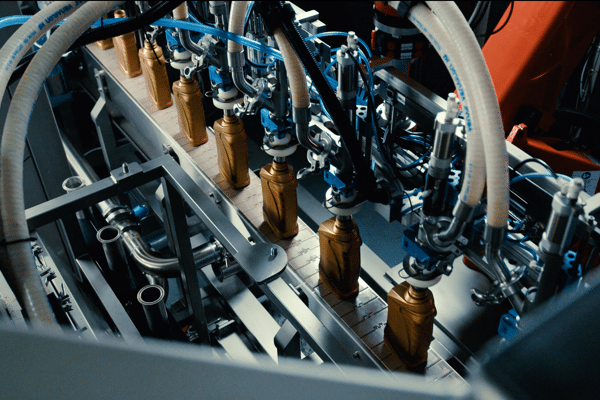

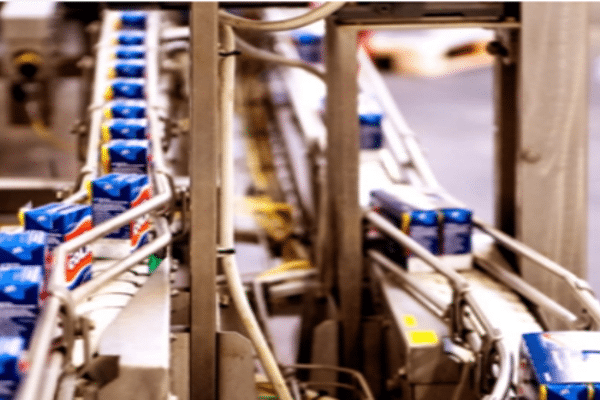

Polskamp Meat Industrie specializes in separating chicken meat from the bone. The production lines run around the clock to process various parts of the chicken into high-qu...

In container handling and transfer operations in ports, a Reachstacker is often used. This machine features horizontal and vertical sliding components

The impact of the new Euro 7 standard is significant. Manufacturers of trucks and buses must comply with strict rules in this environmental standard to drastically reduce t...

Eurol introduces the Geo-Max FE 5W-20 and the Geo-Max SA 5W-30. These are two fully synthetic, fuel-efficient engine oils for modern heavy-duty applications.

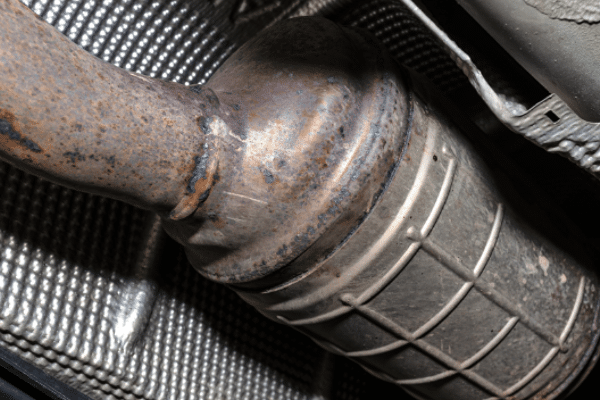

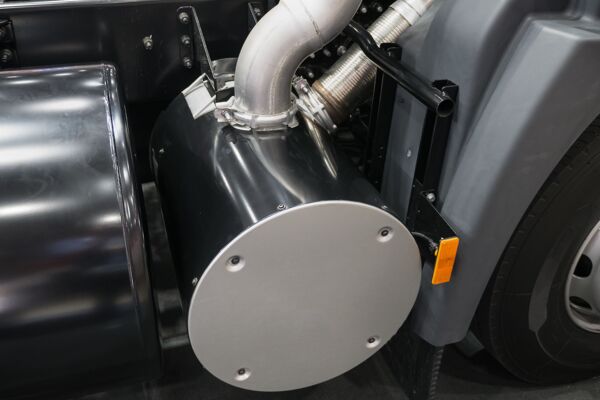

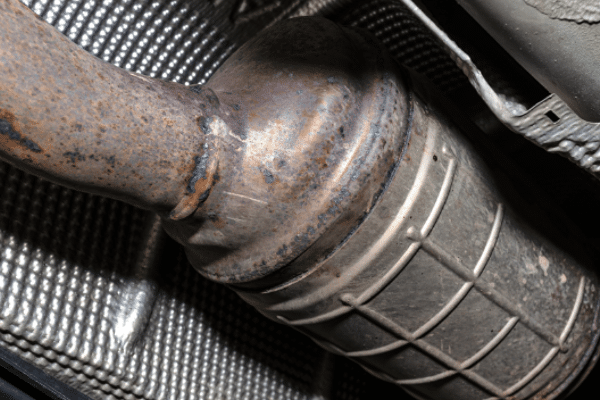

Many trucks are equipped with parabolic springs. The ends of the springs are lubricated for articulation. The radiant heat from regenerating the DPF in the exhaust makes th...

Een baanbrekende oplossing voor duurzaam en efficiënt hervullen van spuitbussen. Leer hoe deze technologie afval vermindert en operationele efficiëntie verbetert.

Under the pressure of increasingly stringent emission requirements in the automotive industry, light, high-revving turbo engines with low cylinder capacity have become the ...

Eurol introduces a food-grade variant and a biodegradable variant of Eurol Lube PL with SYNGIS Technology.

A practical case from a producer in the food industry, who has started saving up to €20,000 per year due to reduced maintenance and downtime thanks to Eurol Specialty produ...

The impact of the new Euro 7 standard is significant. In this knowledge article you can read everything you need to know about the new Euro 7 standard and the role of lubri...

It takes some time getting used to the new season of the TCR Europe Series. We see Tom Coronel racing this season for the first time not in a bright yellow, but black Audi ...

Valtec has been named Specialty Dealer of the Year in Romania again, awarded by Eurol Specialty. The focus is on technical advice and sustainable products, which resulted i...

Eurol supports Rudy van Buren in the FIA European Autocross Championship of 2023. Van Buren is a versatile racing talent, also active as a simulator driver for the Red Bull...

We are proud to share with you our new brand movie. We will reveal more about the future of Eurol; developing innovative lubricants that contribute to groundbreaking perfor...

Eurol introduces the Ultrance Blue 0W-20, a fully synthetic fuel efficient engine oil. Eurol Ultrance Blue 0W-20 is specially developed for Ford EcoBlue diesel engines wher...

Dakar 2023 winners, TOYOTA GAZOO Racing’s Nasser Al-Attiyah and co-driver Mathieu Baumel, are ready for action at the upcoming Abu Dhabi Desert Challenge (ADDC). This rally...

And they do it again! Nasser Al-Attiyah and Mathieu Baumel win the 2023 Dakar Rally. We congratulate Nasser, Mathieu and the entire TOYOTA GAZOO Racing team on this amazing...

Nasser Al-Attiyah has taken his 5th Dakar Rally win after a dominant performance in Saudi-Arabia. Martin van den Brink did the Eurol Rallysport crew proud with a personal b...

The 2023 Dakar Rally is halfway. It’s been a tough first week of the race for everybody involved, but the teams with involvement of Eurol have shined during the eight stage...

In practice, the correct lubrication of agricultural equipment often falls short. Essential lubrication points are not lubricated or not lubricated properly. The result is ...

In the coming week, the teams of both the Dakar and the Classic Dakar Rally will meet the Empty Quarter. A part of the world where nothing lives, where no one comes and whe...

Eurol is renewing the design of its entire packaging line, including Eurol Specialty products. The design has undergone a fresh and modern update along with improved conven...

You probably are familiar with the following situation, you arrive at a traffic light and your engine stops running. Fortunately, it turns back on when you want to drive of...

The 2023 Dakar Rally is about to begin. On New Year's Eve, the starting gun will sound in Saudi Arabia for the first of 14 stages in the world's toughest rally. Eurol is su...

Last weekend, four-time Dakar winner Nasser Al-Attiyah and his French co-driver Mathieu Baumel finished second in the Andalucia Rally.

Eurol will become the new main sponsor of the Mammoet Rallysport team. The Dutch rally team will continue under the name 'Eurol Rally Sport' and will unveil a new team logo...

Curious about our new corporate identity? Read more here!

Kraakman, a John Deere dealer specializing in agricultural, garden, and park machinery, uses Eurol Specialty products.

Valtec, our dealer in Romania, has been named Specialty Dealer of the Year this year. Valtec earns this title because they have acquired more than 150 new customers.

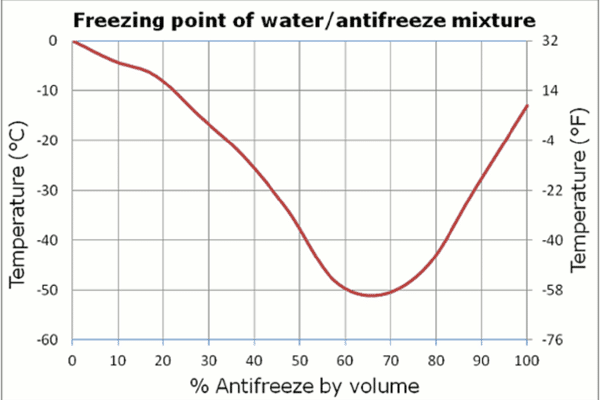

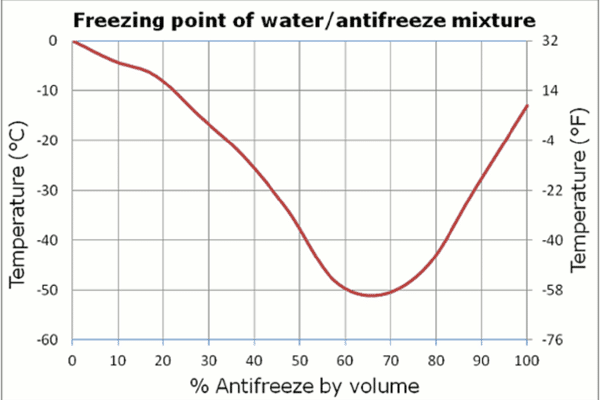

What does a coolant actually do, what are the differences between technologies, and what properties do they have? Why is it no longer possible to make a choice based on the...

Eurol celebrates the Dakar rally victory with a 210 liter barrel in a special full color edition. This limited edition will be deployed from mid-May among the full-sy...

After winning the Dakar Rally earlier this year, Eurol is also supporting Nasser and Mathieu in the new competition: W2RC!

Toyota GAZOO Racing has won the 2022 Dakar rally. Driver Nasser Al Attiyah and navigator Mathieu Baumel set the fastest time on all 12 stages in Saudi Arabia. Toyota's reli...

Nasser Al-Attiyah has won the 2022 Dakar Rally. The Qatari was victorious after a long and tough 12 stages. It’s Al-Attiyah’s 4th win of his Dakar career.

Nasser Al-Attiyah has set his sights on a third overall win in the Dakar Rally. On the penultimate stage the Qatari didn’t make any mistakes, despite it being one of the to...

As the end of the Dakar Rally is starting to become visible, the going gets tough for some of the Eurol supported crews in Saudi Arabia. While bad luck struck for the Riwal...

Giniel de Villiers took his first stage win of this years Dakar Rally in a frantic stage 9. It wasn’t the only success for the teams supported by Eurol as two of De Villier...

“You have to respect the Dakar because the Dakar is the Dakar”, Nasser Al-Attiyah said after a gruelling and long stage 8 in the 2022 Dakar Rally. The Qatari defended his l...

The teams supported by Eurol came out flying on the first day of the second half in this years Dakar Rally. Martin van den Brink drove his best stage of the race while Nass...

After six gruelling stages in the 2022 Dakar Rally, the teams supported by Eurol have deserved a rest day. Stage 6 brought some excellent surprises to round out the first w...

After a few close calls Henk Lategan has finally won his first stage in the Dakar Rally. The South African took the fifth stage, but it was far from easy for the driver of ...

Nasser Al-Attiyah extended his lead in the overall classification on the 4th stage of the Dakar Rally. The Qatari driver did that with a marginal stage win on Wednesday. In...

After a few tough days the third stage of this years Dakar Rally was a bit shorter for the crews supported by Eurol, but a lot happened during the course of the race. Nasse...

After a tough opening stage of the 2022 Dakar Rally, the second stage on Monday was a bit more straightforward for the Eurol supported teams. Nasser Al-Attiyah finished in ...

Nasser Al-Attiyah has taken a commanding stage win on Sunday. The first major stage of the race brought big difficulties for many competitors, but Al-Attiyah benefitted fro...

Toyota Gazoo Racing’s Nasser Al-Attiyah has started 2022 in the best way possible. The Qatari took a big win on Saturday to start of the 2022 Dakar Rally in Saudi Arabia. H...

As of 2011, diesel passenger cars must have a manufacturer-fitted particulate filter to meet European emission requirements. It is therefore all the more important to ensur...

The original ZF automatic transmission fluid was not developed for racing conditions. The protection at high temperatures is not optimal. In addition, the wear was relative...

Too much wear on components and too many different oils in use. Also, the life span of the oil has to be at least 6 Dakar Rally stages.

Eurol once again partner of the TOYOTA GAZOO Racing Team. The new Toyota GR Dakar Hilux, which will also compete in the 2022 FIA World Rally-Raid Championship, is part of T...

From now on the Riwald Dakar team part of the Dakar Future project. The Dakar team has also opted for a hybrid off-road truck for the upcoming Dakar rally.

Eurol introduces the Supreme Classic 10W-40 and 20W-50, mineral engine oils specially developed for classic cars.

The Toyota factory team has been working hard to develop a new Hilux for the 2022 Dakar rally. The new Toyota has received many changes compared to the last version.

A new fully synthetic engine oil for gasoline and diesel engines with official Renault RN17 approval and ACEA C3 classification.

New coolant suitable for modern cars of various Japanese and Korean car brands. This coolant prevents formation of deposits, corrosion, foaming, sludge and leakage.

In the first editions of the Dakar Rally with The Beast, a standard 75W-140 transmission oil was used. This resulted in a rather large amount of wear particles (iron and co...

Eurol teams up with Hendriks Motorsport as its lubricant partner in the NASCAR Whelen Euro Series. The partnership got off to a great start. Filled with Eurol Specialty Rac...

A fifth wheel normally lasts as long as the life of a truck, but in Bolk Transport's situation an extra fifth wheel is most of the time needed.

Trucks are subject to increasingly strict environmental regulations. Not only do emissions of harmful substances need to be reduced, but CO2 emissions also need to come dow...

The new ‘Specialty E-line’ by Eurol guarantees durability, sustainability and efficiency. Eurol sees an enormous growth in the use of heavy duty electrical equipment as a s...

Engine ran on a standard 10W-60 every year. Engine experienced engine wear throughout Dakar rally because of sand ingress. Also occasional drop in oil pressure.

Eurol is once again partner of Tom Coronel in the upcoming racing season of the FIA World Touring Car Cup. Coronel will start with the brand new Audi RS 3 LMS, supported by...

Porsches on track are racing with standard Porsche A40 level engine oil. Owners experienced lower oil pressure when the engine came up to temperature.

The gearbox was operating at more than 130°C sump temperature during a 12h endurance race with the current transmission oil. Outside temperature was approximately 17°C.

Overheating differential in BMW E46 M3 GTR. Differential cannot be filled with 75W-140 because of used oil cooler. Therefore a 75W-90 differential oil with exceptional wear...

Bob de Jong is a famous Dutch rally driver and also the Dutch Rally Champion. Bob is always looking for better performances and less friction for the car by using the best ...

Eurol Specialty introduces a racing lubricant line with groundbreaking properties in wear protection and performance enhancement. Leading racing teams were involved in the ...

Engines tuned for Mobil1 0W-30, difficult to get hold of. Dutch tuner APP Racing Engines works with a NASCAR engine with flat tappet cams which produces more than 150bhp/L,...

A torque converter transfers power from the engine to the transmission. When unlocked, the torque converter constantly slips, causing friction and heat. The Beast 2019 used...

Porsche uses active torque vectoring in a corner by applying the brakes on the inside wheels to increase corner speed. When track racing, applying the brakes in every corne...

During the Dakar Rally, the engine runs at full load for hours, causing temperatures to rise. In these conditions, the engine oil often becomes contaminated with grains of ...

Good lubrication of machines is of great importance. Especially for equipment used in the offshore market, in which environmental and wheather conditions play a major role....

This water-resistant grease has excellent creep properties and is very suitable for machinery in the food and pharmaceutical industries.

Eurol Specialty Lubricants introduces Eurol Grease HY-1/101 FD LT. This new, synthetic foodgrade lubricating grease ensures smooth operation of bearings, especially at very...

The past twelve days have been very challenging, but most of the teams supported by Eurol have reached the finish of the 2021 Dakar. At the end of the race we look back at ...

The second to last stage in the 2021 Dakar Rally was decisive in most categories. Nasser Al-Attiyah took once again a big stage win, but has to settle for second in the gen...

The ninth stage of the 2021 Dakar Rally brought some adversity for the teams supported by Eurol. But even with an uphill battle in the upcoming days, the fighting spirit re...

The 2021 Dakar Rally is well into the second week and every mile is getting more important from now on. On Monday, the competitors from Eurol did their best in a tricky sec...

The second part of the Dakar Rally is underway and there is still a lot to play for. The competitors supported by Eurol started well on Sunday during a tough first part of ...

The competitors supported by Eurol have reached the rest day of the 2021 Dakar. A tough first week took its toll for all the crews, but there’s a lot to fight for with the ...

Competitors in the Dakar Rally reached a whole new level of difficulty on the fifth stage. The teams supported by Eurol fought their way through it and were successful whil...

Nasser Al-Attiyah has taken a third stage win in the 2021 Dakar Rally. The Qatari fought a tremendous battle with young teammate Henk Lategan, who impressed once again. Ove...

The third stage of the 2021 Dakar Rally created some mixed emotions among the teams supported by Eurol. Nasser Al-Attiyah took a big win while Henk Lategan surprised with a...

After losing a few minutes in the first stage of the Dakar, Nasser Al-Attiyah hit back on Monday. The Qatari was the fastest of the cars during the 457 km Bisha to Wadi Ad-...

The prologue was a tasty appetizer for what was to come, but on Sunday the Dakar Rally got underway with a proper first stage. In a stage where danger could be found everyw...

The 2021 Dakar Rally started with a promising result for the competitors of Eurol during this years race. Toyota Gazoo’s Nasser Al-Attiyah was on the money straight away wi...

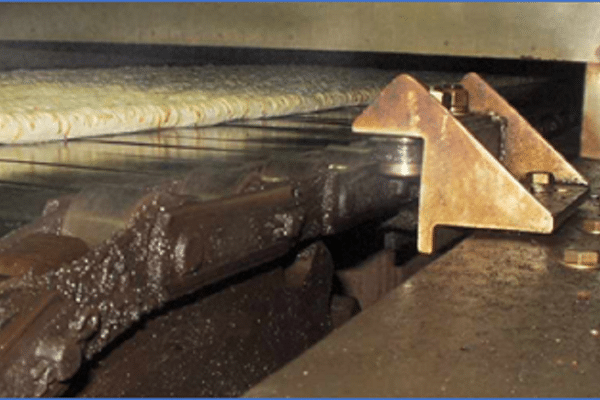

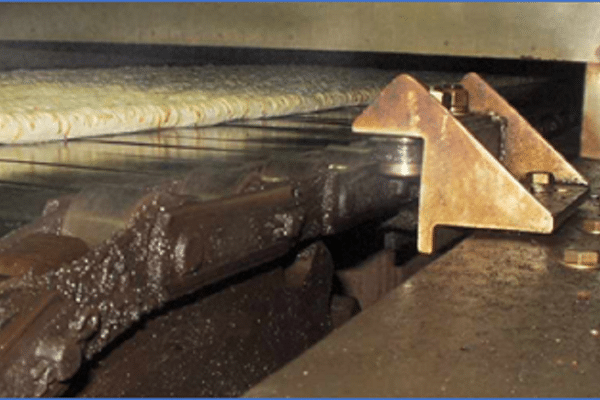

Chains and bearings in a tunnel oven need to be lubricated. However, this is often done with lubricants that are unsuitable for high-temperature applications.

Eurol Specialty introduces a simple solution for the automatic lubrication of various mechanical parts. This lubrication system is highly suitable for situations where regu...

Eurol will be partner of the TOYOTA GAZOO Racing Team for the third year in a row. TOYOTA GAZOO Racing will participate with four teams in the Dakar Rally 2021, which start...

Eurol expands the Bag in box product line with 12 new variants. The expansion leads to in total 31 available products as a result of the increasing demand from th...

Bernhard Ten Brinke and Tom Colsoul have won the Baja Portalegre 500 in Portugal under very tough conditions. This rally was held in preparation for the Dakar Rally 2021...

In the trend towards low viscosity engine oils, we introduce two new fully synthetic engine oils. These have been developed for new generations diesel and petrol engines an...

Tom Coronel and Nathanael Berthon delivered a great performance at the FIA WTCR in Slovakia. Eurol is partner of both drivers and supports the Comtoyou Racing team.

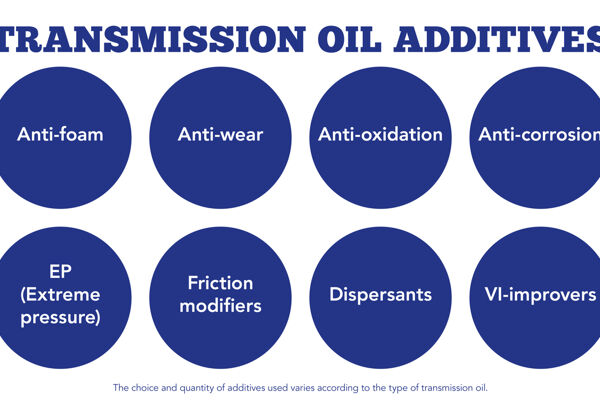

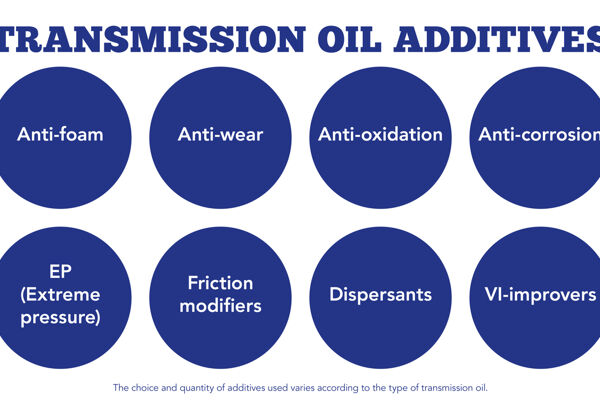

Fuel savings, smoother shifting, extended lifespan, and smaller sump capacities: these are the main driving forces for innovations in the field of transmission.

Eurol launches the Bag in box with a capacity of 20 litres. This new packaging variant fits in the existing Eurol workshop rack of 12 x 20 litres.

Only the best lubricants are good enough for the toughest rally in the world. Curious to find out which Eurol lubricants are used in the Riwald Dakar hybrid truck? Then rea...

Many modern diesel vehicles use AdBlue to meet emission standards. But what is AdBlue and how does it work? In this article we will elaborate on this in more detail.

Due to the Corona crisis, many cars are stationary for a longer period of time. To prevent problems and to get back on the road safely, we would like to give you 5 tips.

Recycling waste residues puts heavy pressure on bearings. Heros Sluiskil chose lubrication that boosts both performance and reliability.

With summer approaching, you naturally want nothing more than to hit the road with your motorcycle again. Do you want to get your motorcycle ready for riding? Then follow t...

Spring is upon us, so it’s time to get your vintage car out of its winter storage! For a smooth and safe start to the new motoring season, Eurol would like to share seven t...

"Sustainability in motorized sports is a sensitive issue for die-hard fans, but the Riwald Dakar Team took a groundbreaking step this year with a Renault hybrid truck. Agai...

A large number of products within the Eurol Specialty range are now Halal certified. "By obtaining the Halal certificate, we offer even more added value."

In order to reduce CO2 emissions, ever stricter requirements for passenger cars are implemented worldwide. Besides innovations in engine technology and material usage, a re...

Especially in these times it’s important to keep your working and home environment clean. Eurol Specialty has a wide range of effective cleaners to help you. We have select...

Eurol is introducing the Eurol Service Point garage formula to the Belgian market. With this, Eurol is meeting the need for an accessible formula that provides garage owner...

Eurol is once again Tom Coronel's partner in the new racing season of the FIA World Touring Car Cup. As a specialist in lubricants, Eurol offers the team products and exper...

Car engines are increasingly being equipped with turbos. A turbo contains advanced technology and is therefore very vulnerable. Problems with a turbo can affect the engine ...

The numbers speak for themselves after finishing the Dakar 2020: teams supported by Eurol did a fantastic job.

In the second day of the marathon stage, all teams had to drive their car exactly as they had brought them to the camp last night.

Due to a severe desert storm, Race Direction of the Dakar Rally decided to considerably shorten today's special stage.

"We drove wisely today," said Bernhard ten Brinke after his solid seventh place in today's stage.

Within the GAZOO Team, the leading roles were reversed today. Now it was Fernando Alonso who scored his first podium place in a Dakar stage, while De Villiers finished four...

"Bernhard ten Brinke impressed today with a rock-solid fourth place. For much of the seventh Dakar stage, speeds were above 170 kilometers per hour."

At the front of the Dakar 2020, an epic battle is raging between three legends: Sainz, Peterhansel and "our" Nasser Al-Attiyah.

At the front of the rally it's going very fast this year. Today there was a scoop on top, in a transition from rocky ground to more sand, with large rocks along the side.

It seems easy to get used to, but also today the Dakar 2020 participants who maintain their technicals with Eurol lubricants scored big time.

After yesterday's first Eurol victory, the Toyota GAZOO teams were again very close today, all cars finished in the Top 10 today.

Today stage two of the Dakar 2020 was mainly about rocky ground, with lots of loose stones and sharp rock points. But despite that it was Giniel to claim first day victory ...

This morning the Dakar 2020 started, for the first time the toughest rally in the world is held in Saudi Arabia. After Africa and South America, the third chapter of the le...

Mario Kress, General Manager of MKR Technology is the developer and builder of the Riwald Rallysport Renault Truck C460 Hybrid Edition. This will be the first hybrid truck ...

Mario Kress, General Manager van MKR Technology, is ontwikkelaar en bouwer van de eerste hybride Dakar truck: de Renault Truck C460 Hybrid Edition voor het Riwald Dakar Tea...

Increasingly, we are seeing handy devices on the market that let us gauge brake fluid quality. However, given the frequent question of whether these devices are reliable, E...

Eurol introduces the Eurol Evolence 0W-16, a fully synthetic engine oil for petrol engines. This low viscous, fuel-saving engine oil has been developed for the latest model...

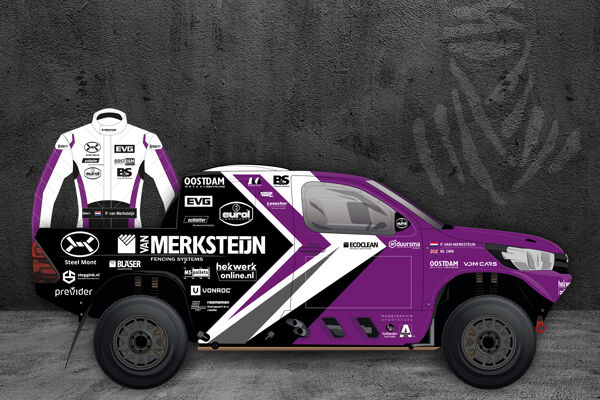

Peter van Merksteijn is going for a new Dakar Rally adventure! Eurol is once again the lubricants partner of Van Merksteijn Motorsport during ...

The new Renault Truck C460 Hybrid Edition truck has won the Preproloog 2019! The truck with the Eurol Specialty lubricated hybrid drive was the fastest to complete the thre...

Wood shredders do heavy work. Thanks to our lubricants, they run longer with less downtime, lower consumption, and improved bearing lubrication.

Eurol has obtained the ISO 21469:2006 certificate. With this certification, Eurol shows that it meets the internationally recognised standard for hygiene requirem...

TOYOTA GAZOO Racing today announced an all-star line-up for the Dakar Rally scheduled to take place for the first time in Saudi Arabia in January 2020.

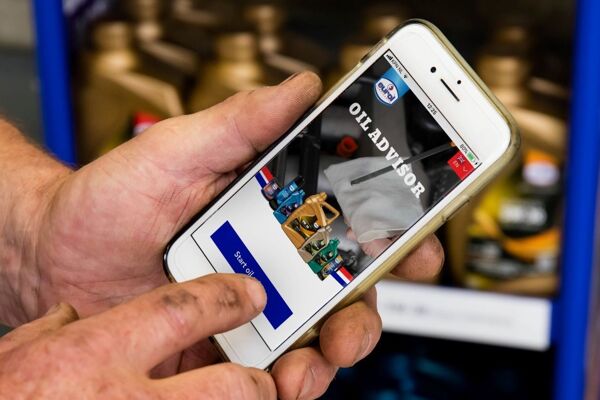

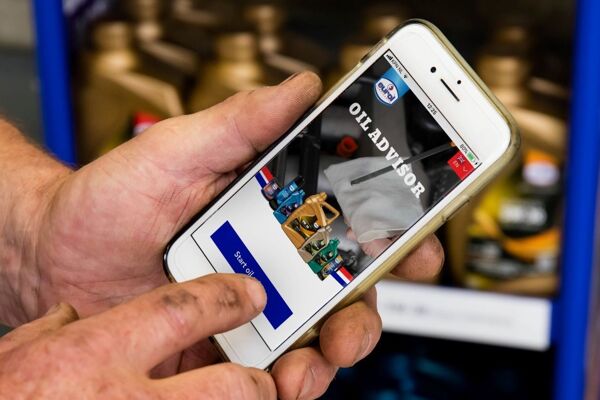

Eurol's online oil advisor is now available via an app: ‘Eurol Oil Advisor’. With this app, Eurol makes it even easier for you to obtain oil advices, anywhere and anytime.&...

With Eurol as a proud partner, Toyota Gazoo Racing SA drivers Giniel De Villiers and Alex Haro have won the final victory in the Rallye du Maroc 2019.

Looking for the right lubricants for an Old Timer? From now on, classic cars are also included in the Eurol product advisor on the Eurol website.

In tough conditions, proper lubrication helps mowers deliver top performance. At JvESCH, this led to less maintenance and lower costs.

Official press release from Toyota Gazoo Racing SA concerning Eurol sponsorship deal for Dakar 2020.

The Riwald Dakar Team and Czech partner MKR Technology, have been working hard for months on the development of an entirely new and unique concept; a hybrid off-road truck....

Rally driver Jasper van den Heuvel and his navigator Lisette Bakker have won the Eurol Hellendoorn Rally for the first time in their career. Rally team Bernhard ten Brinke ...

Downtime of parking machines costs money. With the right lubrication, they remain reliable and require significantly less frequent maintenance.

Under the name 'Additive-S', Eurol Specialty Lubricants introduces a new line of high-quality additives with SYNGIS Technology. The product line has been extensively tested...

"To finish first, you first have to finish." This saying couldn't be more relevant to the sport of rallying, as it prevents winning teams from skimping on their materials –...

Grease is grease, right? "Not exactly, our lubricants are completely different in composition compared to regular lubricants." Automotive trade magazine AMT recently visite...

Lubrication is a specialty. As a lubricant manufacturer and specialist, we are happy to share our knowledge with you. That is why from now on you will find various knowledg...

Specific Eurol products are requested for different makes and types of cars. This raises both logistical and administrative issues, which requires managing all these produc...

Eurol celebrates the recent Dakar victory of Nasser Al-Attiyah and Mathieu Baumel with a special print on the barrels and drums. Both packaging variants will be delivered i...

Tom Coronel will participate in the 2019 TCR Europe Championship in a Honda Civic. Last season we already saw the driver in action in the Civic during the WTCR championship...

The World Touring Car Cup season is about to begin. This year Eurol supports Tom Coronel and Aurélien Panis. Both drivers will ride as team mates in a CUPRA for the Belgian...

Nasser Al-Attiyah has won the 2019 Dakar Rally in a dominant fashion. During the last stage, the Toyota Gazoo Racing driver took no risk at all during the ultimate stage of...

Nasser Al-Attiyah start the last stage of the 2019 Dakar Rally with an advantage of 51 minutes in the overall classification. The Qatari took a commanding win during a diff...

BREAKING NEWS: Nasser Al-Attiyah and Mathieu Baumel, drivers of the Toyota GAZOO Racing team, have won the Dakar rally of 2019!

Janus van Kasteren had presented the Mammoet Rallysport Team with his best stage result in only his second Dakar appearance. The Dutchman finished in fifth in what was cons...

Tim and Tom Coronel had a remarkable two days in the 2019 Dakar Rally. The guys finished the big seventh stage in 26th place after a long adventure in the desert. Eurol fol...

Nasser Al-Attiyah showed another strong performance during the sixth stage of the 2019 Dakar Rally. The Qatari now leads the race with a healthy advantage, but there are st...

The longest stage of the 2019 Dakar Rally proved to be a real big challenge for all Eurol teams. Eurol supports the brave competitors to the 2019 Dakar Rally and reports on...

Nasser Al-Attiyah has taken his second stage win of the 2019 Dakar Rally and is leading the overall classification as of the fourth stage.

Janus van Kasteren took a great sixth place during one of the toughest stages of this years Dakar Rally. The Dutchman finished right behind the fastest guys and gained a lo...

After a short first stage, the Dakar Rally really started on Tuesday with a 342 kilometre long stage. Bernhard ten Brinke finished third in the car category. Eurol is suppo...

During the wintertime it can be difficult to start your engine. Eurol offers two additives who help, also when your car feels slow or lazy.

Eurol is the official sponsor of Toyota GAZOO Racing. All the drivers of this factory team will drive with the Dutch lubricant brand during the upcoming 2019 edition of the...

The environment reigns and manufacturers have to apply the craziest tricks to allow cars to comply with emission standards.

The successful collaboration between Bernhard ten Brinke and Eurol will be continued in 2019. The Dutch Dakar driver will be participating in the Dakar Rally 2019 with the ...

A decade or so ago, garage mechanics could only choose between two oils. Today, however, that number has increased at least fivefold. ‘Car manufacturers have their own engi...

Only the best lubrication is good enough to become a BMX World Champion! Therefore Laura and Merel Smulders use Eurol Specialty lubricants with SYNGIS Technology for the ma...

Eurol has obtained the ISO 14001:2015 environmental management certificate. With this certification, Eurol demonstrates that it meets all the requirements of the standard a...

Eurol introduces Elance 5W-30, a fully synthetic, long-life engine oil for petrol and diesel engines that complies with the new Renault RN17 standard, API SN, and the ACEA ...

Eurol introduces the ATF 7400, a transmission oil that meets the new Mercedes MB236.17 specification. The ATF 7400 is ideally suited for the new 9-speed transmissions from ...

Eurol is delighted to introduce the Eurol Protence 5W-30 GN II. This oil meets the GM Dexos 1 generation II specification and offers extra protection against LSPI (low spee...

The Dakar Rally has proven that Eurol Specialty lubricants lubricate and protect optimally, even in the most extreme conditions. This demonstration film shows the high qual...

The truck parts lubricated with Eurol Specialty in Mammoet trucks have been thoroughly inspected after the Dakar Rally. The analysis shows that despite the extreme pressure...

Eurol supported the participants of the 2018 Dakar Rally. In the past two weeks they completed the most gruelling race of the world under extremely difficult conditions.

Eurol supports the participants of the 2018 Dakar Rally. On the penultimate stage of the rally, Bernhard ten Brinke suffered a major dissapointment after an engine failure....

Eurol supports the participants of the Dakar Rally 2018. Today Bernhard ten Brinke took an impressive fifth place during a long and extremely hot stage to San Juan.

Eurol supports the competitors of the 2018 Dakar Rally. The 11th stage was an exceptional day for the Eurol-teams with a historic stage win by Bernhard ten Brinke and co-dr...

Eurol supports the competitors of the 2018 Dakar Rally. After an unforseen second rest day the competitors of the Dakar Rally went further on their tour through Argentina.

Eurol supports the competitors in the Dakar Rally. On Sunday all Eurol-teams finished the second part of the marathon stage succesfully and heard that they will have a day ...

The Mammoet Rallysport team uses Eurol Specialty lubricants, including during the Dakar Rally 2018. Mario Kress, manager of MKR Technology, shares his findings.

After six tough days the riders, drivers, co-drivers and mechanics of the Eurol-teams reached La Paz for a well deserved rest day. Eurol supports them through out the Dakar...

Eurol supports the participants of the 2018 Dakar Rally. During the fifth stage on Wednesday Bernhard ten Brinke gained another two places in the general classification.

Eurol supports the participants of the Dakar Rally. Bernhard ten Brinke did The Netherlands proud in the fourth stage of the Dakar by finishing seventh and gaining a lot of...

Eurol supports participants in the Rally Dakar 2018. On the third day of the rally all Eurol-teams were back in business after a difficult day during the second stage.

Each year Eurol supports participants of the Dakar Rally. The 2018 edition of the Dakar is no exception with a lot of talented riders and crews. On Saturday the race starte...

Eurol rally driver Bernhard to Brinke returns to the Dakar Rally 2018 as a member of the Toyota Gazoo Racing South Africa team.

More and more diesel engines in cars, trucks and agricultural vehicles use AdBlue to reduce harmful NOx emissions. Eurol introduces a high-quality AdBlue in a handy 5 and 1...

Eurol launches a fuel additive line especially developed for motorcycles. The product range consists of four products: Eurol Motorcycle Fuel Treat, Eurol Motorcycle System ...

Eurol continues the partnership with driver Tom Coronel in the FIA World Touring Car Championship (WTCC). The sponsorship started last year and is in line with the intern...

Johan Pfeiffer started his business Eurol exactly 40 years ago on 1 February 1977. Under his management, Eurol grew to become a major international oil brand now available ...

De-icing salt can be very aggressive towards bearings and other parts of the de-icing salt spraying equipment. Our Specialty greases Eurol Grease CS2 / 101, 501 and 501-S w...

Eurol introduces a top-quality additives range. At the Automechanika trade fair in Frankfurt from 16-20 September, the extended range was presented for the first time to th...

Working in mud, sand and water can become very complicated because of the wear of bearings and other parts of the tracks on a tracked vehicle. One of our customers is speci...

Our product Eurol Lube PL-S with Syngis Technology performs very well in lubricating the plates of (light) railway switches

With the introduction of 'Specialty Lubricants,' Eurol launches a line of high-quality specialized lubricants that help to save costs and increase efficiency.

Why local heat is decisive for the cooling strategy of Volvo heavy duty engines and what this means for coolant selection and maintenance.

The Eurol-teams experienced an eventful Dakar Rally 2026 with seven stage victories, a podium for Mitchel van den Brink and strong debuts by Kay Huzink and Ian Olthof.

Young talent is showing its best side during the first week of Dakar 2026, delivering strong performances in the truck, car and motorcycle categories.

In Dakar 2026, Eurol will appear at the start with a wide representation. With four trucks, four cars and one motorcycle, it promises to be an exciting edition. ...

Improved lubrication and corrosion protection increased reliability, lowered maintenance costs and reduced downtime in demanding tunnel drill applications.

Discover how modern two- and four-stroke engines evolve due to emission standards and what this means for maintenance, oil choice and machine performance.

Eurol introduces the Actence 0W-16, developed for the latest hybrid and petrol engines from Renault & Dacia.

Discover how Eurol Grease CS 2 103S prevents severe wear and downtime in a Haeusler CNC roller through pressure resistant lubrication and stable flow behaviour.

Foam formation in wet brake systems can lead to pressure loss, wear, and malfunctions. Read how this occurs, what the consequences are, and how to prevent it.

Rocco Coronel, Red Bull Junior, has claimed the G40 Junior Championship title with 11 victories and 19 podium finishes.

Reliable spindle lubrication with Eurol Grease CS-2/502-S. Prevent wear, leakage, and drying with long-lasting SYNGIS Technology protection.

Industrial gearboxes require reliable lubrication to prevent energy loss, wear, and downtime. In this article, you will learn how modern lubrication strategies – from advan...

Eurol and Invicta Racing launch a technical F2 partnership with SYNGIS Technology for greater performance, efficiency, and reliability in Formul...

TBN indicates the acid-neutralising capacity of an oil. Essential when using sulphur-rich fuel and under heavy-duty conditions, to protect against corrosion and wear.

By switching to Eurol Grease CS-2/103-S, a rubble recycler saves 9 hours of downtime per week, with smooth automatic drum start-up and no more manual rocking required.

Brake fluid is often overlooked but crucial for a safely operating braking system. This article explains what to consider when choosing and replacing it.

Eurol supports Ian Olthof, the only Dutch motorcycle rider in the Dakar Rally 2026. Ian has been relying on Eurol products for years and represents the brand in the rally.

Driving on holiday? Avoid breakdowns with these 5 smart fluid-check tips. Set off worry-free and well-prepared for your journey.

Powerful and sustainable lubrication for heavy-duty applications. Discover three new bio-lubricants with SYNGIS Technology that deliver top performance under all conditions...

Additive-S BIO lowers the oil temperature of the Toro Greensmaster, enabling more efficient and sustainable mowing with reduced maintenance.

Alex Palou wins the 109th Indianapolis 500 for Chip Ganassi Racing. Eurol, as a technical partner, made an essential contribution to this achievement.

Poor diesel quality causes clogged injectors and engine problems in the transport sector. Discover how a smart fuel additive not only cuts breakdowns in half but also saves...

Salt and heavy loads caused failures in the loading system at Bolk Transport. With Eurol Lube CL-F Spray, everything runs smoothly again.

Prevent rust damage to your boat trailer with the right protection and extend the lifespan of vital components.

A small van with starting issues, loss of power, and increased consumption is expertly and repaired by our.

Lama Chemie is the fastest growing dealer in sustainable and specialty lubricants from Eurol in 2024.

Specialized lubrication extends the lifespan and enhances the efficiency of trailing suction hopper dredgers under harsh conditions.

Noroil wins the Eurol Specialty Dealer of the Year Award 2024 thanks to strong growth in industrial lubricants and technical fluids in Norway.

A crane company was faced with severe corrosion on the jib cables of their mobile tower cranes, leading to high maintenance costs and complex inspections

A frequently asked question is whether a chain should be lubricated with grease or oil. In this article, we explain the differences between oil and grease and provide advic...

Discover the Eurol Swift Clean HD Wipes for effortless cleaning water and the Swift Clean 130 - now also available in a 20L can for high-volume users.

A taxi company, with an extensive fleet of vehicles equipped with automatic transmissions, is experiencing increasing complaints about the shifting behavior of some of thei...

NSF approval guarantees safety when used correctly, but does not mean that a product is 'Foodsafe' for direct food contact. Understanding the different NSF categories helps...

The Dakar Rally 2025 concludes successfully for the Eurol teams: Mitchel van den Brink and Henk Lategan shine with both securing 2nd place in the final standings!

Because of internal combustion engine downsizing, a new phenomenon occurs more often: Low Speed Pre Ignition (LSPI). LSPI cannot be heard and cannot be foreseen, however it...

Discover which Eurol lubricants contribute to the success of Toyota GAZOO Racing in the Dakar Rally. We apply our expertise from the toughest rally in the world to innovati...

After five tough Dakar stages, the Eurol participants enjoy a well-deserved rest day. Both teams experienced successes and setbacks.

Eurol will partner with Chip Ganassi Racing as a technical partner for the 2025 INDYCAR SERIES season.

Eurol supports top teams ready for the 47th edition of the Dakar Rally, taking place from January 3 to 17, 2025, in Saudi Arabia.

Eurol launches the Lube PL-S spray, a versatile dry lubricant with SYNGIS Technology, now updated and expanded with sustainable variants.

Eurol strengthens its partnership with young racing talent Rocco Coronel, who, alongside his karting activities, is now also supported in the Ginetta Junior Championship.

Extreme conditions in mining cause wear and downtime. Eurol offers solutions to improve the lifespan and efficiency of machinery.

Eurol introduces four new products, developed for various vehicles, including modern passenger cars, trucks, and light commercial vehicles.

The new Eurol Screenwash Safe Storage offers a solution without storage restrictions, is safe to use, and guarantees excellent cleaning.

Using Eurol Assembly Paste HT/FD for drilling equipment in the steel industry prevents carbonization, extends machine lifespan, and reduces downtime, saving over €50,000 an...

We are introducing ‘Carbon Neutral,’ a line of lubricants that are fully CO2-neutral.

Visit Eurol during Automechanika in Frankfurt from September 10 to 14, 2024. Hall 12, stand E11.

The Dutch lubricant manufacturer Eurol has acquired Eurol Lubricants Österreich.

We introduce the Fultrax 75W-90 LS, a fully synthetic transmission oil with limited slip properties.

Using an engine oil flush additive when changing the engine oil is a simple way to prevent and remedy engine contamination. It takes little time and has multiple benefits.

Mitchel van den Brink and navigator Bart van Heun from the Eurol Rally Sport team have won the 2024 Morocco Desert Challenge in the overall SSV classification.

In the production of prefabricated decorative paving, a large automatic steel brush for keeping the molds clean plays a crucial role in ensuring quality.

Tom Coronel will continue his racing activities this season with technical support from Eurol, participating in the Nuerburgring Langstreckenmeisterschaft in a Porsche 911 ...

Keep your racing bike in optimal condition. By using the professional Eurol Specialty products, you make a difference on the bike and in the workshop.

Eurol is proud to announce that we are the new lubricant partner of rally talent Yannick Vrielink. The 25-year-old racer, who clinched the champion title of the Dutch Toyot...

Organizations in various sectors are considering biodegradable hydraulic oils due to sustainability and regulations, despite past doubts.

We introduce the Transfluid ATF-CVT, a revolution in transmission fluid technology. This is the first fully synthetic transmission oil suitable for both conventional automa...

We introduce the Eurol Coolant -36°C G12 EVO. This is a state-of-the-art coolant developed from LOBRID PSi-OAT technology, specifically for the latest generation vehicles o...

Distributor Valtec from Romania has received the International Eurol Specialty Distributor award for the third consecutive year.

In the vertical transport sector, proper lubrication of sliding parts and steel cables is crucial. Outdated greases can lead to malfunctions and increased maintenance. Mode...

Nowadays, modern specialized solutions are available to save energy while simultaneously optimally protecting industrial gearboxes against wear and leakage..

Lubricant color codes are an integral part of maintaining a safe and efficient industrial working environment. Read more in this knowledge article.

The final stage of the 2024 Dakar Rally has concluded! Today, the drivers tackled a challenging 175 km stretch through rocky terrain, culminating in a stunning finish along...

After six tough stages, the participants are enjoying a well-deserved rest day. The first week of the Dakar has proven to be a real endurance test for various teams.

There are various reasons for temporarily decommissioning machines. One crucial step is essential to ensure a trouble-free restart.

Reducing the CO2 footprint of industrial processes is becoming increasingly important. In this, energy saving plays a crucial role.

With the 2024 Dakar Rally approaching, Saudi Arabia will once again be the backdrop for the world's toughest rally from January 5 to 19.

Toyota GAZOO Racing was seeking solutions to increase durability in their race cars and improve performance.

Eurol announces the introduction of the Ultrance ST 0W-20 engine oil, an advanced fuel-saving and fully synthetic formula.

Cleaning the sliding parts with brake cleaner was a labor-intensive process and unfavorable from an occupational health perspective. The worker had to protect themselves ag...

The lubrication of sliding parts is often done with standard grease. Unlike oil, this grease is not easily applied with a brush.

Discover how an innovative lubricant transforms the efficiency and sustainability of transport and road construction equipment, such as loading cranes, grabs, dump trucks, ...

The hydraulic systems of these pile driving machines were constantly under heavy load, which resulted in a shortened lifespan of the pump.

The door locking mechanism of sea containers operates through a lever principle. The hinges and the lock or closing mechanism are traditionally lubricated with lithium grea...

Eurol Specialty CS-2/501 and CS-2/101 have contributed to a significant reduction in wear on the propeller shafts.

In heavy-duty earthmoving equipment, the lubrication of pin-in-bush connections plays a crucial role in maintaining the performance and lifespan of the machines.

For agricultural contractors, the reliability of their equipment is central to a successful and efficient operation.

Eurol introduces E Heavy Duty Lube 46 BIO, a groundbreaking hydraulic oil specially developed for electric excavators.

SMESH have developed a modular e-axle with integrated E-motor, clutch packs and planetary gear systems.

We introduce E Heavy Duty, a new generation of lubricants specially developed for the efficient lubrication of electrified heavy machinery and vehicles.

We hereby announce the launch of our new website, E-Commerce environment, Product Information Management system, and Brand Po...

We warmly welcome you to the AgriTechnica fair in Hanover, the world’s largest trade fair for agricultural machinery.

In a factory for plastic recycling and waste management, they encountered a challenge, namely repeated defects in bearings in shredders and dryers.

Certain cleaning agents can damage the conveyor chains and gears of the car wash. The cleaning agents are so strong that they dissolve standard lubricants, leaving the chai...

Tom Coronel has become champion in the TCR Europe Series for the first time in his illustrious racing career in 2023.

Toyota GAZOO Racing has become world champion in the Rally-Raid discipline for the second consecutive year.

In a construction involving reinforced concrete and prestressed steel cables, "Anchors," or steel clamps, are used to tension and hold the cables.

The disc coulter bearings of the manure injector undergo heavy loads and come into contact with manure, sand, and water. The ammonia present in the manure leads to an alkal...

At an agricultural facility that processes hay and straw, operators discovered problems with the conveyor chains. The chains were wet and sticky, attracting dust, sand and ...

Recently, there have been significant developments regarding the Euro 7 emission standards for passenger cars, light commercial vehicles, and heavy commercial vehicles.

On a golf course, typically five types of lawnmowers are used to maintain all the different types of grass and terrains in good condition.

We will showcase our Eurol Specialty Racing lubricants with SYNGIS Technology at the international racing fair in Köln Messe, Cologne, Germany on November 8 and 9.

Proper lubrication of machinery is essential. This is certainly true for gritters that need to keep our roads safe to drive on during the winter months. In this case study,...

The sequential gearbox is equipped with dog clutches as synchronizers. These dog clutches are often subject to high wear, as they need to engage while the vehicle is operat...

Engine is developed for competition use. All engines are sealed, only performance benefits can be achieved by altering lubricants such as the engine oil. Eurol Racing 0W-40...

Bob de Jong is a famous Dutch rally driver and also the Dutch Rally Champion. Bob is always looking for better performances and less friction for the car by using the best ...

Flowability issues when using a fluid grease. Also possibility of misapplication between different parts of the truck, such as transfer case, differentials and hub reductio...

Van den Boogaard is specialized in transport, heavy salvage, and crane rental. The equipment, including truck mounted cranes, must be available day and night under all circ...

The transmission oils have to protect all lubricated parts during the complete Dakar Rally with minimal friction and wear. The previously used products were acceptable but ...

At Riwald Recycling in Almelo, a lot of work is done with grabs on cranes. The cranes and grabs rotate all day long and an extreme amount of force is put on the moving part...

Polskamp Meat Industrie specializes in separating chicken meat from the bone. The production lines run around the clock to process various parts of the chicken into high-qu...

In container handling and transfer operations in ports, a Reachstacker is often used. This machine features horizontal and vertical sliding components

The impact of the new Euro 7 standard is significant. Manufacturers of trucks and buses must comply with strict rules in this environmental standard to drastically reduce t...

Eurol introduces the Geo-Max FE 5W-20 and the Geo-Max SA 5W-30. These are two fully synthetic, fuel-efficient engine oils for modern heavy-duty applications.

Many trucks are equipped with parabolic springs. The ends of the springs are lubricated for articulation. The radiant heat from regenerating the DPF in the exhaust makes th...

Een baanbrekende oplossing voor duurzaam en efficiënt hervullen van spuitbussen. Leer hoe deze technologie afval vermindert en operationele efficiëntie verbetert.

Under the pressure of increasingly stringent emission requirements in the automotive industry, light, high-revving turbo engines with low cylinder capacity have become the ...

Eurol introduces a food-grade variant and a biodegradable variant of Eurol Lube PL with SYNGIS Technology.

A practical case from a producer in the food industry, who has started saving up to €20,000 per year due to reduced maintenance and downtime thanks to Eurol Specialty produ...

The impact of the new Euro 7 standard is significant. In this knowledge article you can read everything you need to know about the new Euro 7 standard and the role of lubri...

It takes some time getting used to the new season of the TCR Europe Series. We see Tom Coronel racing this season for the first time not in a bright yellow, but black Audi ...

Valtec has been named Specialty Dealer of the Year in Romania again, awarded by Eurol Specialty. The focus is on technical advice and sustainable products, which resulted i...

Eurol supports Rudy van Buren in the FIA European Autocross Championship of 2023. Van Buren is a versatile racing talent, also active as a simulator driver for the Red Bull...

We are proud to share with you our new brand movie. We will reveal more about the future of Eurol; developing innovative lubricants that contribute to groundbreaking perfor...

Eurol introduces the Ultrance Blue 0W-20, a fully synthetic fuel efficient engine oil. Eurol Ultrance Blue 0W-20 is specially developed for Ford EcoBlue diesel engines wher...

Dakar 2023 winners, TOYOTA GAZOO Racing’s Nasser Al-Attiyah and co-driver Mathieu Baumel, are ready for action at the upcoming Abu Dhabi Desert Challenge (ADDC). This rally...

And they do it again! Nasser Al-Attiyah and Mathieu Baumel win the 2023 Dakar Rally. We congratulate Nasser, Mathieu and the entire TOYOTA GAZOO Racing team on this amazing...

Nasser Al-Attiyah has taken his 5th Dakar Rally win after a dominant performance in Saudi-Arabia. Martin van den Brink did the Eurol Rallysport crew proud with a personal b...

The 2023 Dakar Rally is halfway. It’s been a tough first week of the race for everybody involved, but the teams with involvement of Eurol have shined during the eight stage...

In practice, the correct lubrication of agricultural equipment often falls short. Essential lubrication points are not lubricated or not lubricated properly. The result is ...

In the coming week, the teams of both the Dakar and the Classic Dakar Rally will meet the Empty Quarter. A part of the world where nothing lives, where no one comes and whe...

Eurol is renewing the design of its entire packaging line, including Eurol Specialty products. The design has undergone a fresh and modern update along with improved conven...

You probably are familiar with the following situation, you arrive at a traffic light and your engine stops running. Fortunately, it turns back on when you want to drive of...

The 2023 Dakar Rally is about to begin. On New Year's Eve, the starting gun will sound in Saudi Arabia for the first of 14 stages in the world's toughest rally. Eurol is su...

Last weekend, four-time Dakar winner Nasser Al-Attiyah and his French co-driver Mathieu Baumel finished second in the Andalucia Rally.

Eurol will become the new main sponsor of the Mammoet Rallysport team. The Dutch rally team will continue under the name 'Eurol Rally Sport' and will unveil a new team logo...

Curious about our new corporate identity? Read more here!

Kraakman, a John Deere dealer specializing in agricultural, garden, and park machinery, uses Eurol Specialty products.

Valtec, our dealer in Romania, has been named Specialty Dealer of the Year this year. Valtec earns this title because they have acquired more than 150 new customers.

What does a coolant actually do, what are the differences between technologies, and what properties do they have? Why is it no longer possible to make a choice based on the...

Eurol celebrates the Dakar rally victory with a 210 liter barrel in a special full color edition. This limited edition will be deployed from mid-May among the full-sy...

After winning the Dakar Rally earlier this year, Eurol is also supporting Nasser and Mathieu in the new competition: W2RC!

Toyota GAZOO Racing has won the 2022 Dakar rally. Driver Nasser Al Attiyah and navigator Mathieu Baumel set the fastest time on all 12 stages in Saudi Arabia. Toyota's reli...

Nasser Al-Attiyah has won the 2022 Dakar Rally. The Qatari was victorious after a long and tough 12 stages. It’s Al-Attiyah’s 4th win of his Dakar career.

Nasser Al-Attiyah has set his sights on a third overall win in the Dakar Rally. On the penultimate stage the Qatari didn’t make any mistakes, despite it being one of the to...

As the end of the Dakar Rally is starting to become visible, the going gets tough for some of the Eurol supported crews in Saudi Arabia. While bad luck struck for the Riwal...

Giniel de Villiers took his first stage win of this years Dakar Rally in a frantic stage 9. It wasn’t the only success for the teams supported by Eurol as two of De Villier...

“You have to respect the Dakar because the Dakar is the Dakar”, Nasser Al-Attiyah said after a gruelling and long stage 8 in the 2022 Dakar Rally. The Qatari defended his l...

The teams supported by Eurol came out flying on the first day of the second half in this years Dakar Rally. Martin van den Brink drove his best stage of the race while Nass...

After six gruelling stages in the 2022 Dakar Rally, the teams supported by Eurol have deserved a rest day. Stage 6 brought some excellent surprises to round out the first w...

After a few close calls Henk Lategan has finally won his first stage in the Dakar Rally. The South African took the fifth stage, but it was far from easy for the driver of ...

Nasser Al-Attiyah extended his lead in the overall classification on the 4th stage of the Dakar Rally. The Qatari driver did that with a marginal stage win on Wednesday. In...

After a few tough days the third stage of this years Dakar Rally was a bit shorter for the crews supported by Eurol, but a lot happened during the course of the race. Nasse...

After a tough opening stage of the 2022 Dakar Rally, the second stage on Monday was a bit more straightforward for the Eurol supported teams. Nasser Al-Attiyah finished in ...

Nasser Al-Attiyah has taken a commanding stage win on Sunday. The first major stage of the race brought big difficulties for many competitors, but Al-Attiyah benefitted fro...

Toyota Gazoo Racing’s Nasser Al-Attiyah has started 2022 in the best way possible. The Qatari took a big win on Saturday to start of the 2022 Dakar Rally in Saudi Arabia. H...

As of 2011, diesel passenger cars must have a manufacturer-fitted particulate filter to meet European emission requirements. It is therefore all the more important to ensur...

The original ZF automatic transmission fluid was not developed for racing conditions. The protection at high temperatures is not optimal. In addition, the wear was relative...

Too much wear on components and too many different oils in use. Also, the life span of the oil has to be at least 6 Dakar Rally stages.

Eurol once again partner of the TOYOTA GAZOO Racing Team. The new Toyota GR Dakar Hilux, which will also compete in the 2022 FIA World Rally-Raid Championship, is part of T...

From now on the Riwald Dakar team part of the Dakar Future project. The Dakar team has also opted for a hybrid off-road truck for the upcoming Dakar rally.

Eurol introduces the Supreme Classic 10W-40 and 20W-50, mineral engine oils specially developed for classic cars.

The Toyota factory team has been working hard to develop a new Hilux for the 2022 Dakar rally. The new Toyota has received many changes compared to the last version.

A new fully synthetic engine oil for gasoline and diesel engines with official Renault RN17 approval and ACEA C3 classification.

New coolant suitable for modern cars of various Japanese and Korean car brands. This coolant prevents formation of deposits, corrosion, foaming, sludge and leakage.

In the first editions of the Dakar Rally with The Beast, a standard 75W-140 transmission oil was used. This resulted in a rather large amount of wear particles (iron and co...

Eurol teams up with Hendriks Motorsport as its lubricant partner in the NASCAR Whelen Euro Series. The partnership got off to a great start. Filled with Eurol Specialty Rac...

A fifth wheel normally lasts as long as the life of a truck, but in Bolk Transport's situation an extra fifth wheel is most of the time needed.

Trucks are subject to increasingly strict environmental regulations. Not only do emissions of harmful substances need to be reduced, but CO2 emissions also need to come dow...

The new ‘Specialty E-line’ by Eurol guarantees durability, sustainability and efficiency. Eurol sees an enormous growth in the use of heavy duty electrical equipment as a s...

Engine ran on a standard 10W-60 every year. Engine experienced engine wear throughout Dakar rally because of sand ingress. Also occasional drop in oil pressure.

Eurol is once again partner of Tom Coronel in the upcoming racing season of the FIA World Touring Car Cup. Coronel will start with the brand new Audi RS 3 LMS, supported by...

Porsches on track are racing with standard Porsche A40 level engine oil. Owners experienced lower oil pressure when the engine came up to temperature.

The gearbox was operating at more than 130°C sump temperature during a 12h endurance race with the current transmission oil. Outside temperature was approximately 17°C.

Overheating differential in BMW E46 M3 GTR. Differential cannot be filled with 75W-140 because of used oil cooler. Therefore a 75W-90 differential oil with exceptional wear...

Bob de Jong is a famous Dutch rally driver and also the Dutch Rally Champion. Bob is always looking for better performances and less friction for the car by using the best ...

Eurol Specialty introduces a racing lubricant line with groundbreaking properties in wear protection and performance enhancement. Leading racing teams were involved in the ...

Engines tuned for Mobil1 0W-30, difficult to get hold of. Dutch tuner APP Racing Engines works with a NASCAR engine with flat tappet cams which produces more than 150bhp/L,...

A torque converter transfers power from the engine to the transmission. When unlocked, the torque converter constantly slips, causing friction and heat. The Beast 2019 used...

Porsche uses active torque vectoring in a corner by applying the brakes on the inside wheels to increase corner speed. When track racing, applying the brakes in every corne...

During the Dakar Rally, the engine runs at full load for hours, causing temperatures to rise. In these conditions, the engine oil often becomes contaminated with grains of ...

Good lubrication of machines is of great importance. Especially for equipment used in the offshore market, in which environmental and wheather conditions play a major role....

This water-resistant grease has excellent creep properties and is very suitable for machinery in the food and pharmaceutical industries.

Eurol Specialty Lubricants introduces Eurol Grease HY-1/101 FD LT. This new, synthetic foodgrade lubricating grease ensures smooth operation of bearings, especially at very...

The past twelve days have been very challenging, but most of the teams supported by Eurol have reached the finish of the 2021 Dakar. At the end of the race we look back at ...

The second to last stage in the 2021 Dakar Rally was decisive in most categories. Nasser Al-Attiyah took once again a big stage win, but has to settle for second in the gen...

The ninth stage of the 2021 Dakar Rally brought some adversity for the teams supported by Eurol. But even with an uphill battle in the upcoming days, the fighting spirit re...

The 2021 Dakar Rally is well into the second week and every mile is getting more important from now on. On Monday, the competitors from Eurol did their best in a tricky sec...

The second part of the Dakar Rally is underway and there is still a lot to play for. The competitors supported by Eurol started well on Sunday during a tough first part of ...

The competitors supported by Eurol have reached the rest day of the 2021 Dakar. A tough first week took its toll for all the crews, but there’s a lot to fight for with the ...

Competitors in the Dakar Rally reached a whole new level of difficulty on the fifth stage. The teams supported by Eurol fought their way through it and were successful whil...

Nasser Al-Attiyah has taken a third stage win in the 2021 Dakar Rally. The Qatari fought a tremendous battle with young teammate Henk Lategan, who impressed once again. Ove...

The third stage of the 2021 Dakar Rally created some mixed emotions among the teams supported by Eurol. Nasser Al-Attiyah took a big win while Henk Lategan surprised with a...

After losing a few minutes in the first stage of the Dakar, Nasser Al-Attiyah hit back on Monday. The Qatari was the fastest of the cars during the 457 km Bisha to Wadi Ad-...

The prologue was a tasty appetizer for what was to come, but on Sunday the Dakar Rally got underway with a proper first stage. In a stage where danger could be found everyw...

The 2021 Dakar Rally started with a promising result for the competitors of Eurol during this years race. Toyota Gazoo’s Nasser Al-Attiyah was on the money straight away wi...